Microwave sulfur lamp with rised energy coupled field intensity

A technology of energy coupling and microwave, applied in the direction of discharge lamps, electrical components, circuits, etc., can solve the problem of low energy coupling efficiency and achieve the effect of enhancing light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

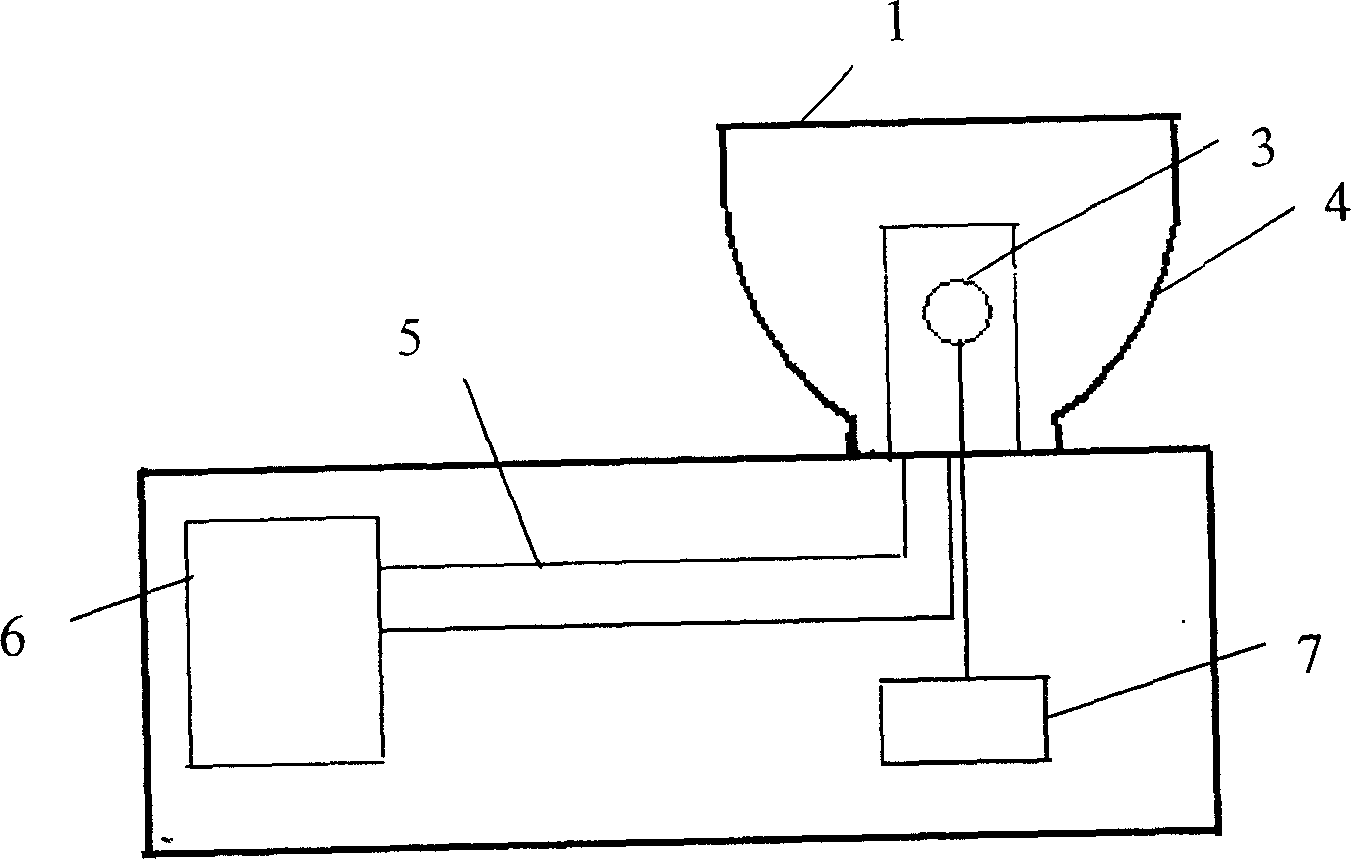

[0016] The microwave sulfur lamp with improved energy coupling field strength of the present invention will be described with reference to the accompanying drawings and embodiments.

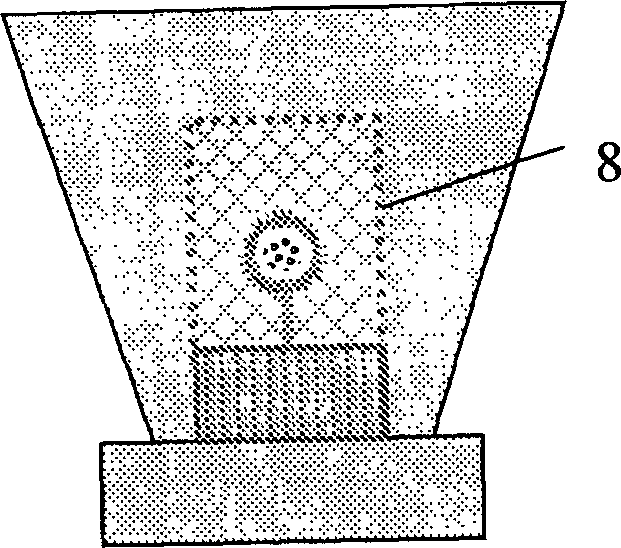

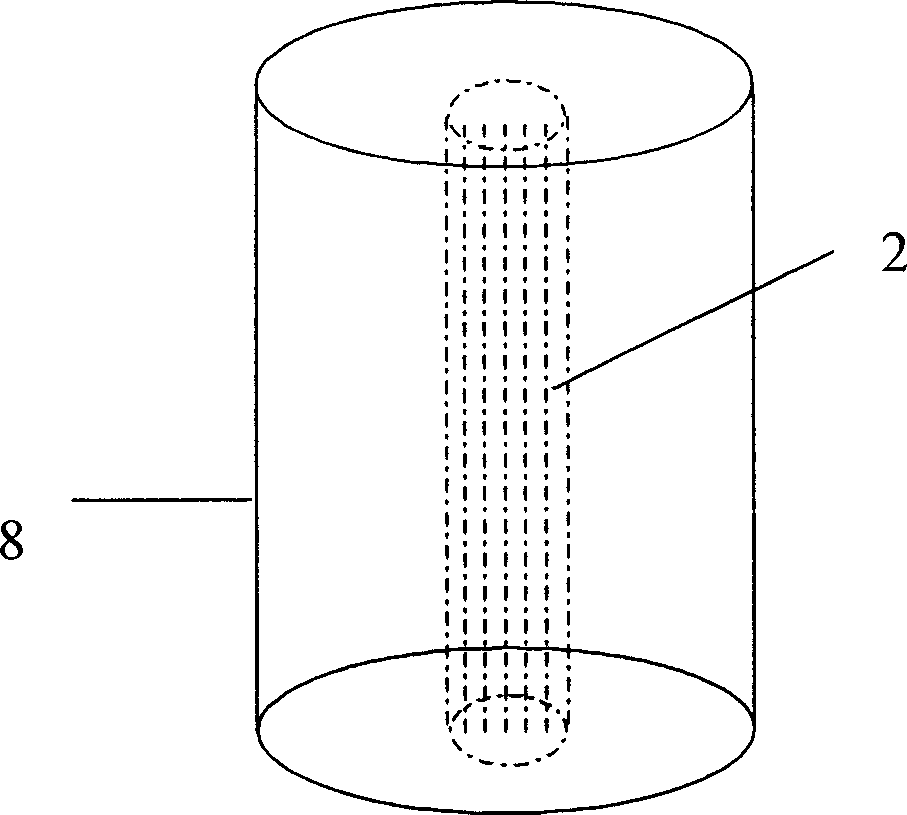

[0017] The structure of the microwave sulfur lamp for improving the energy coupling field strength of the present invention includes a magnetron 6 that emits microwaves, a quartz bulb 2, a mesh cover 8 sleeved outside the quartz bulb 2, and the shape of the quartz bulb 2 It has a cylindrical shape and is on the same axis as the mesh cover 8 so that the field strength of the microwave energy coupling from the magnetron 6 is distributed on the coaxial line of the mesh cover 8.

[0018] The working principle of the system is as follows: the magnetron generates microwaves driven by DC high voltage, and transmits them to the resonant cavity through the wave guide. The microwaves are coupled with the sulfur plasma contained in the quartz bulb in the resonant cavity to excite sulfur molecular radiation. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com