Voltage boosting type device and method of consecutive correcting power factor in average electric current control mode

A technology of power factor correction and average current control, applied to output power conversion devices, control/regulation systems, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

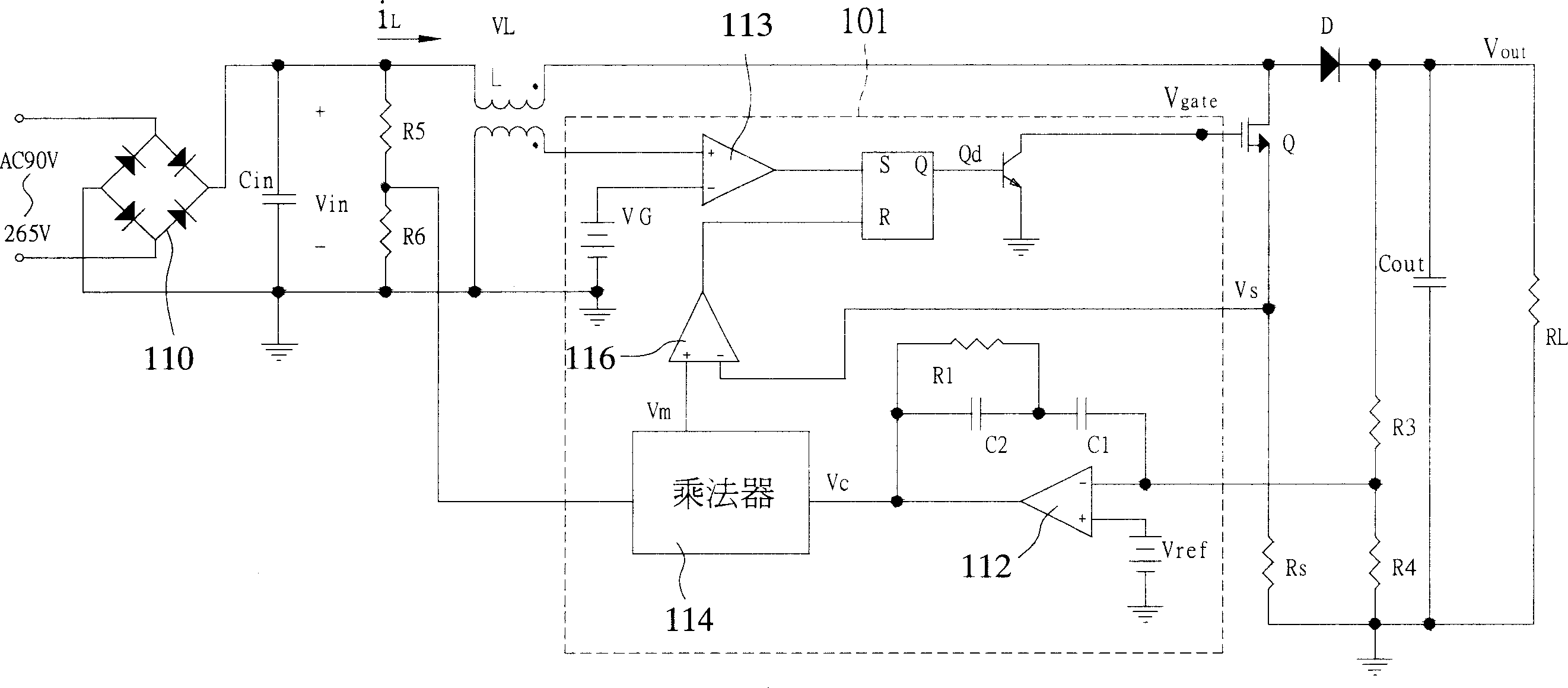

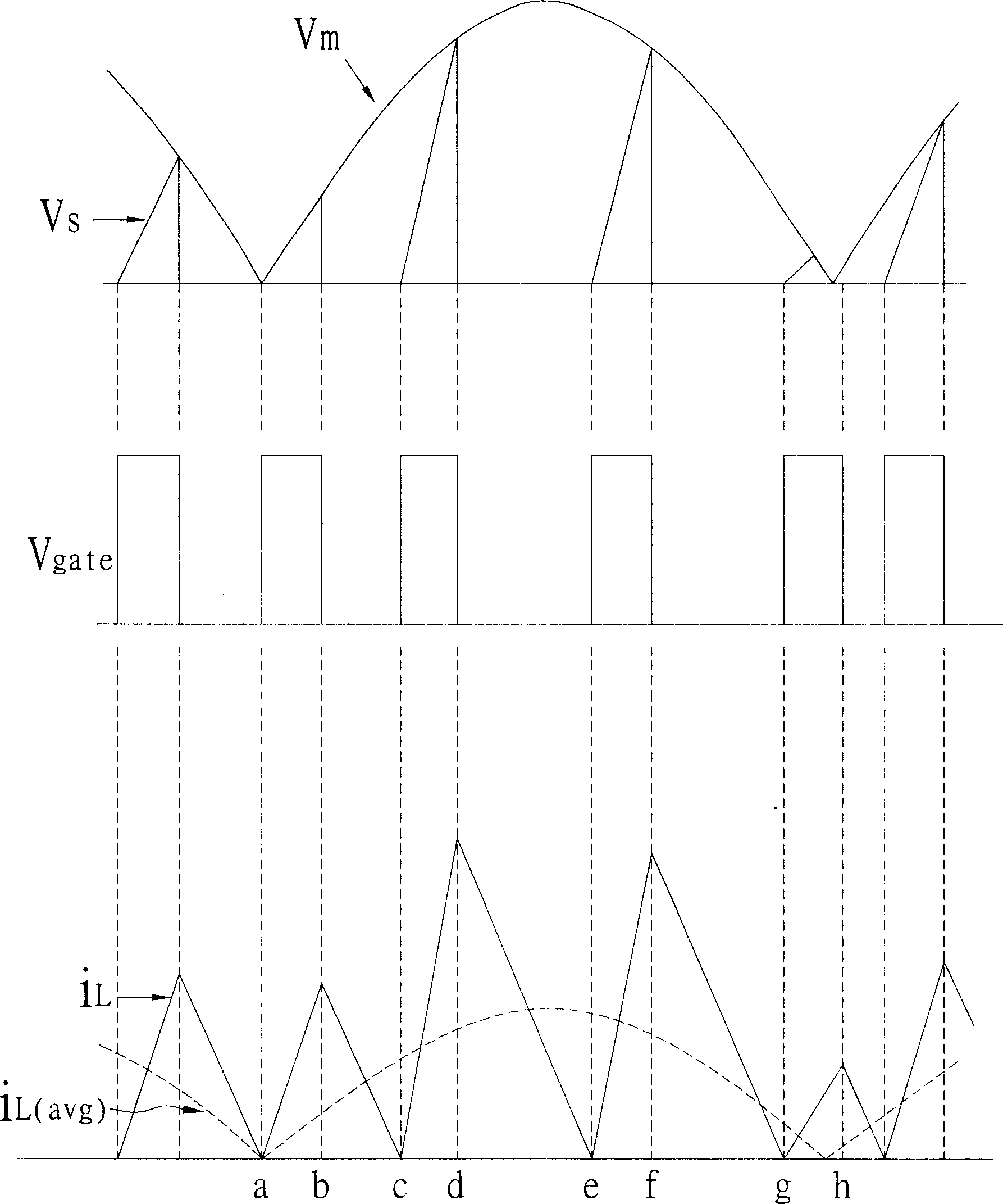

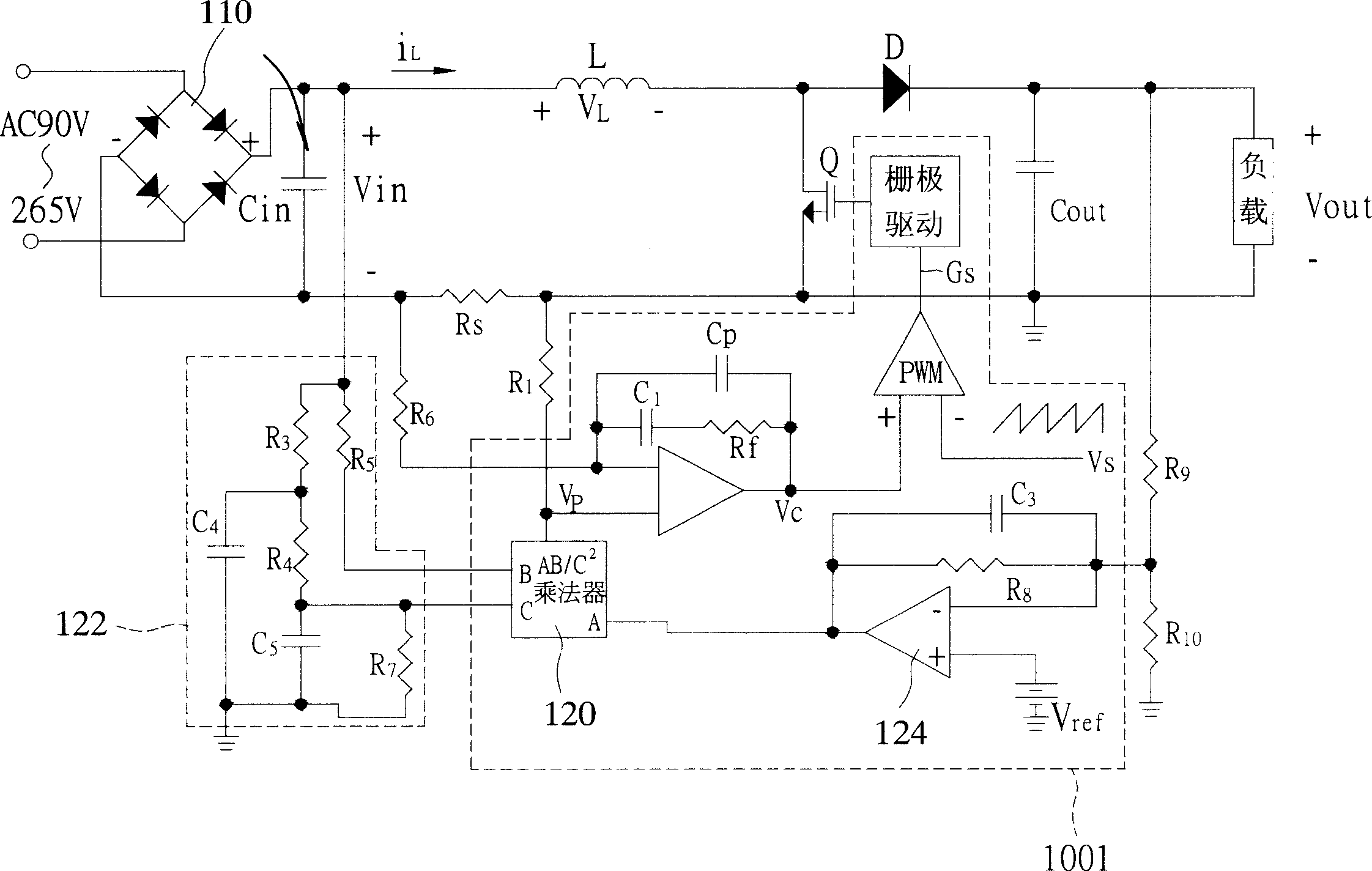

[0051] see Figure 5 , is a schematic diagram of the structure of the first preferred AC / DC power converter used in the present invention. The step-up continuous power factor correction device 1 in the average current control mode of the present invention controls the input by controlling the periodic switching action of a switch Q. Current I in Then control the input voltage V rectified by the rectifier device BD in , so that the input current I of the AC / DC power converter in with input voltage V in It is proportional and in phase, and can obtain high power factor and low total harmonic distortion (Total Harmonic Distortion; THD).

[0052] please cooperate Figure 5 refer to Figure 6 , which is a schematic circuit block diagram of the first embodiment of the present invention. The step-up continuous power factor correction device 1 of the average current control mode of the present invention is applied in the AC / DC power converter, and is used to control the switching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com