Cooling device for vehicle dry type two clutches

A dual-clutch and cooling device technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of small heat capacity and poor heat dissipation ability, and achieve improved heat dissipation ability, reliable operation, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further elaborated below in conjunction with the accompanying drawings.

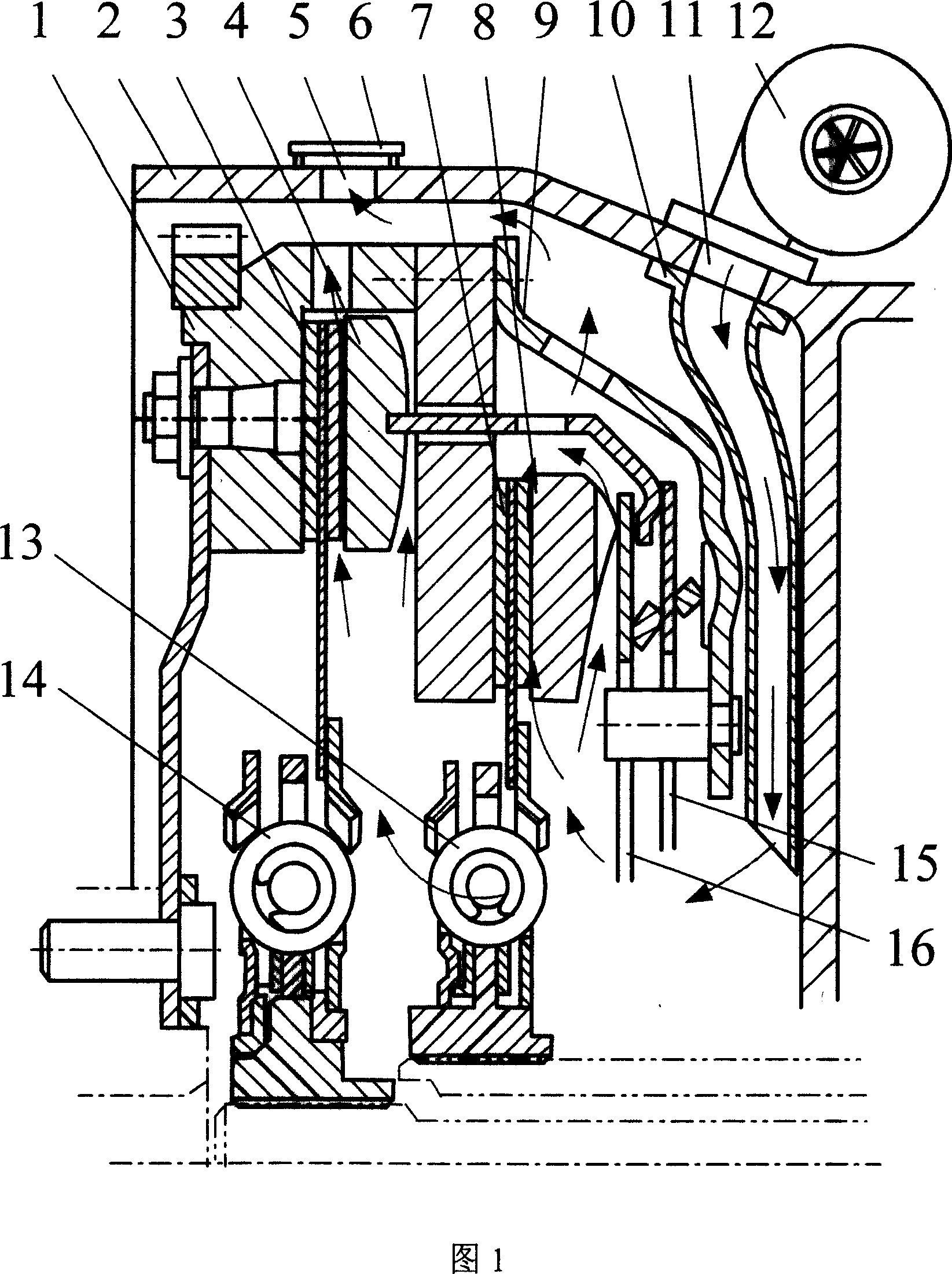

[0009] Fig. 1 has provided the structure of the present invention and the schematic diagram of the flow of cooling air, on the clutch housing 2 an air outlet 5 and an air inlet 11 are arranged, and on the clutch housing 2 the outside of the air outlet 5 is provided with a dust cover 6 , to prevent dirt and dust from entering. A motor-driven blower 12 is installed at the position of the air inlet 11 on the clutch housing 2, and a cooling air guide pipe 10 is installed at the position of the air inlet 11 in the clutch housing 2. The blower 12 is driven by the automobile power supply, and the cooling air blown out From the outlet of the guide tube 10 to the middle part of the clutch, and through the first clutch diaphragm spring 15 and the second clutch diaphragm spring 16, part of the cooling air passes through the back of the second clutch pressure plate 8 and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com