Permanent magnetic amtipodal gear wheel

An energy-gathering and permanent magnet technology, which is applied in the direction of belts/chains/gears, components with teeth, and the magnetism of inorganic materials, can solve the problem that there is no permanent magnet energy-gathering tooth and non-ferromagnetic wheel base mosaic structure, and power cannot be transmitted , more magnetic flux leakage and other problems, to achieve the effect of good mechanical buffer, small mechanical vibration and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

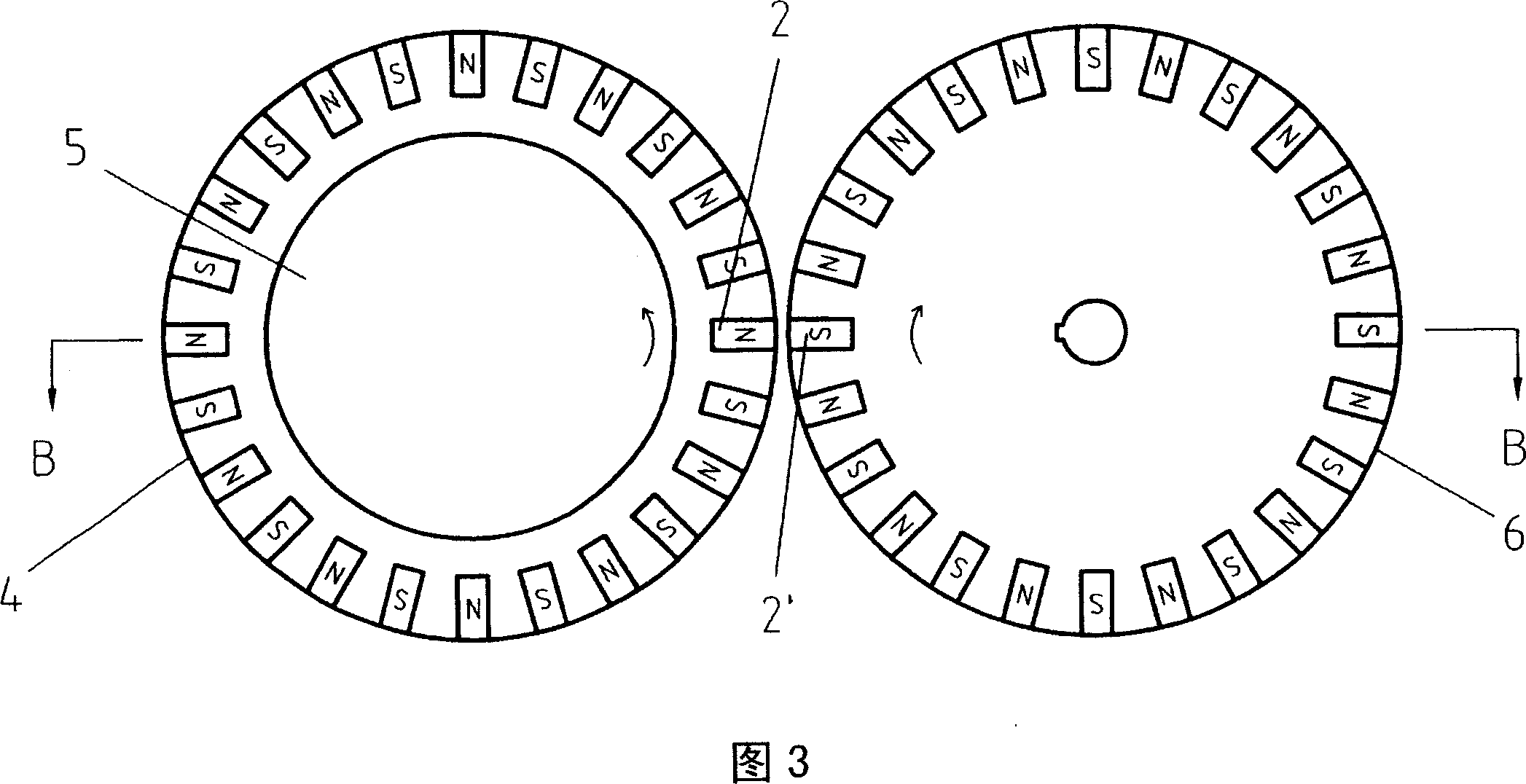

[0020] The following content is a detailed description of the present invention in conjunction with the accompanying drawings, but should not be construed as a limitation of the present invention.

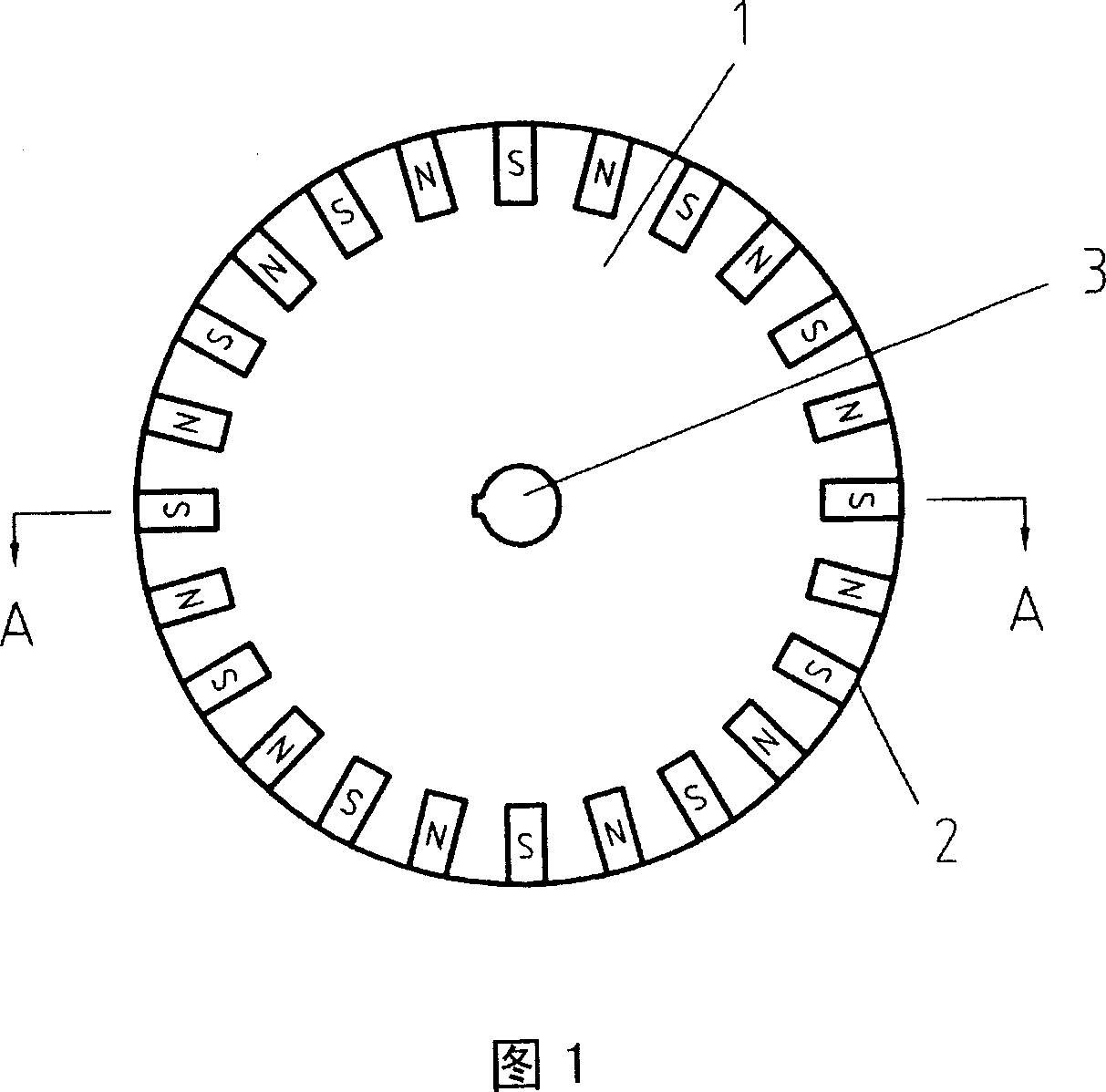

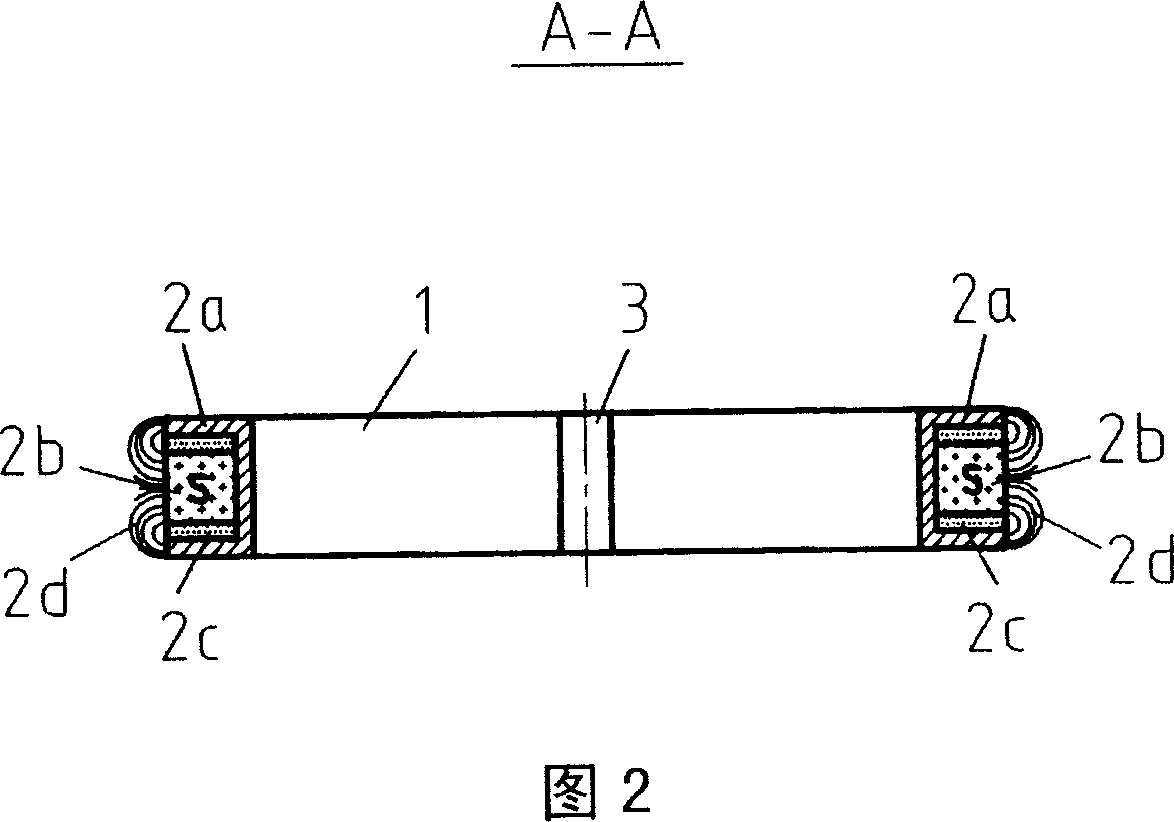

[0021] Please refer to Fig. 1, which is a schematic diagram of the general structure of the present invention. The wheel base 1 is made of non-ferromagnetic material (such as but not limited to: polytetrafluoroethylene, copper or aluminum, etc.), the circumference of the wheel rim is provided with gaps at equal intervals, and the center of the wheel base 1 is provided with a wheel shaft hole 3, To fix the wheel base 1 on the wheel axle. Permanent magnet energy-gathering teeth 2 are inlaid in the openings of the wheel base 1. The permanent magnet teeth 2 are dark teeth, and the surface thereof transitions smoothly with the rim, but here the magnetic field strength is highlighted on the non-ferromagnetic rim. A permanent magnet "field tooth" is formed.

[0022] The structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com