Method for improving level-dyeing property of chitin/cotton fiber mixed fabrics

A fabric dyeing and blending fabric technology, applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve problems such as difficult to achieve level dyeing effect, complicated process, energy consumption, etc., to improve level dyeing, simplify Dyeing process, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, a kind of processing method that improves dyeing levelness of chitin / cotton blended fabric comprises:

[0027] Pretreatment: Accurately weigh 2g of chitin / cotton (5 / 95, 8 / 92, 10 / 90, 12 / 88 or 20 / 80) blended fabric, add 40g of water with a bath ratio of 1:20, add cationic etherification agent ( 3-chloro-2-hydroxypropyltrimethylammonium chloride or 2,3-epoxypropyltrimethylammonium chloride) 20g / L, sodium hydroxide 5g / L and JFC0.5g / L, warming up to Stir continuously at 100°C, keep warm for 20 minutes, then cool down to 40°C, dehydrate, rinse with clean water, dehydrate, dry, and use as the fabric to be dyed.

[0028] Dyeing: Take 2g of the fabric to be dyed, and prepare the dye solution at a bath ratio of 1:20, add reactive red B-3BF, reactive orange-2RLN or Megafix yellow B-4GLN1% (percentage relative to the quality of the fabric to be dyed), and add O 0.5g / L, JFC 0.5g / L; dyeing temperature 80°C, dyeing time 30min.

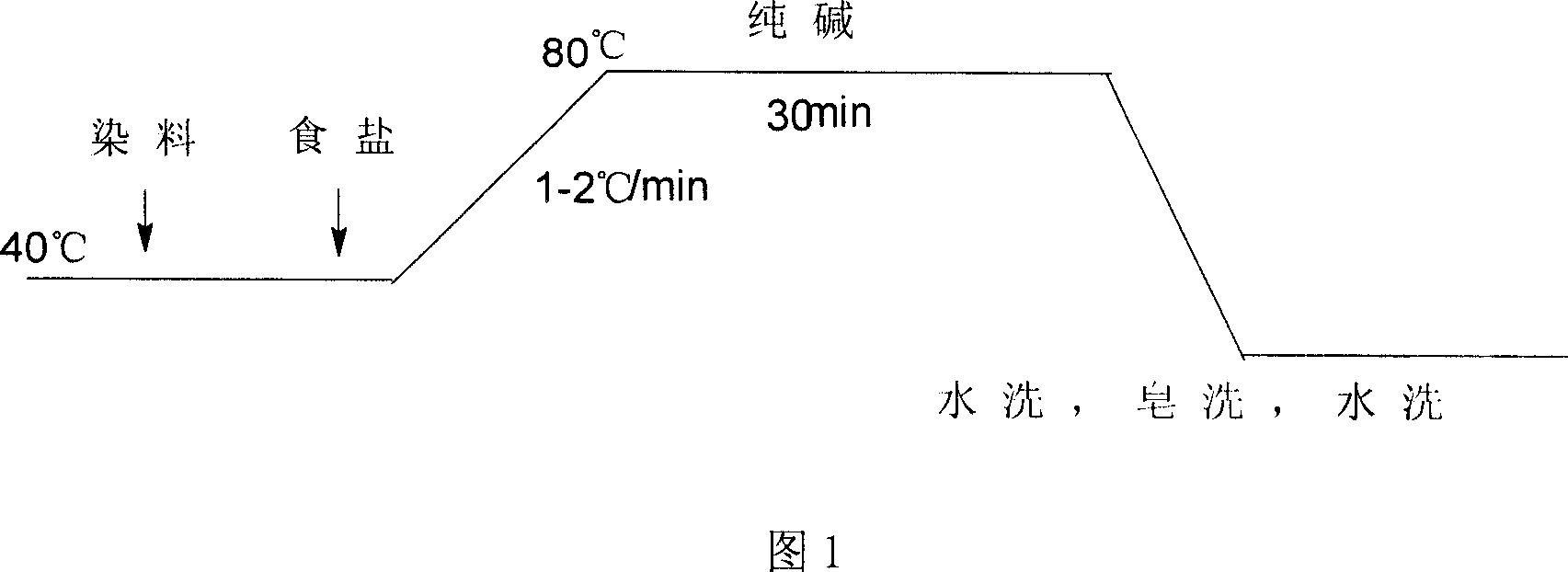

[0029] The dyeing process curve is shown...

Embodiment 2

[0031] Embodiment 2, a kind of processing method that improves dyeing levelness of chitin / cotton blended fabric comprises:

[0032] Pretreatment: Accurately weigh 2g of chitin / cotton (5 / 95, 8 / 92, 10 / 90, 12 / 88 or 20 / 80) blended fabric, add 80g of water at a bath ratio of 1:40, add cationic etherification agent ( 3-chloro-2-hydroxypropyltrimethylammonium chloride or 2,3-epoxypropyltrimethylammonium chloride) 70g / L, sodium hydroxide 25g / L and JFC2g / L, heat up to 40°C , stirring continuously, keeping warm for 60 minutes, then cooling down to 20°C, dehydrating, rinsing with clean water, dehydrating, and drying, as the fabric to be dyed.

[0033] Dyeing: Take 2g of the fabric to be dyed, and prepare the dye solution according to the bath ratio of 1:50, add reactive red B-3BF, reactive orange-2RLN or Megafix yellow B-4GLN1% (percentage relative to the quality of the fabric to be dyed), add O evenly 2g / L, JFC 2g / L; dyeing temperature 80°C, dyeing time 30min.

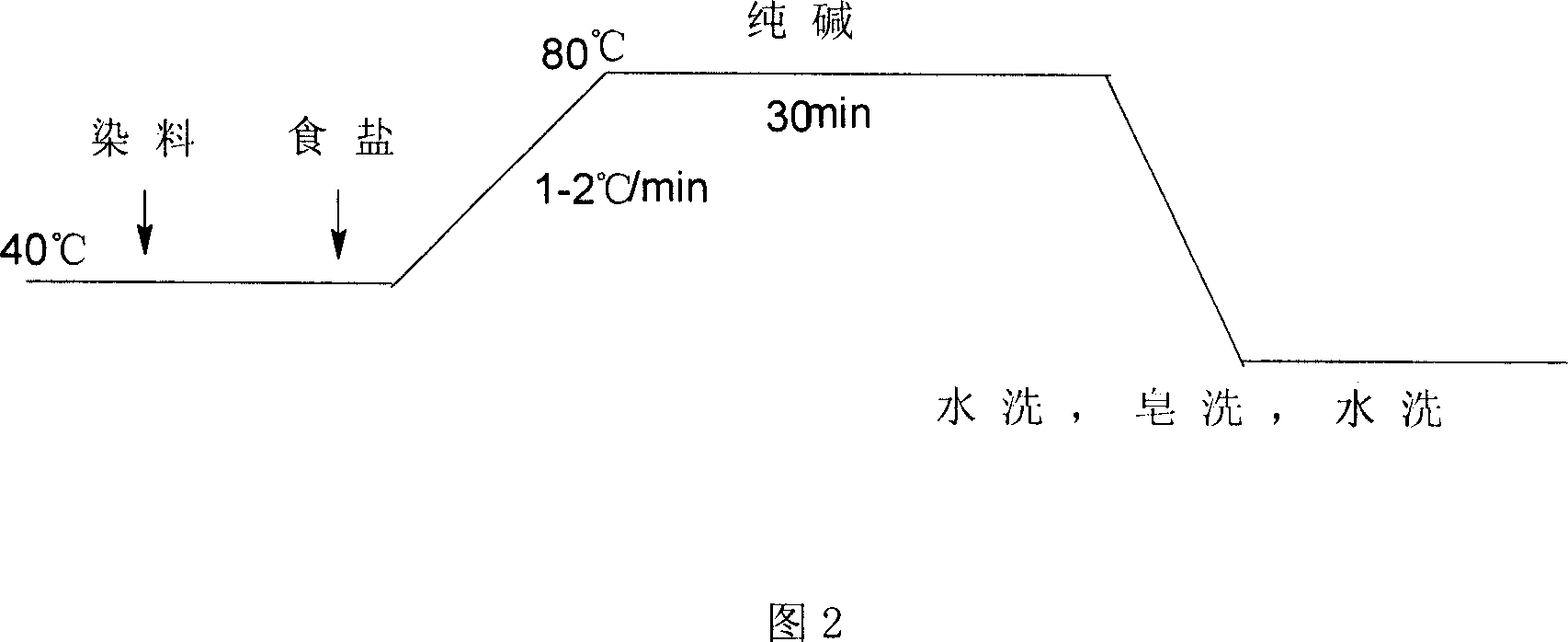

[0034] The specific dy...

Embodiment 3

[0036] Embodiment 3, a kind of processing method that improves dyeing levelness of chitin / cotton blended fabric comprises:

[0037] Pretreatment: Accurately weigh 2g of chitin / cotton (5 / 95, 8 / 92, 10 / 90, 12 / 88 or 20 / 80) blended fabric, add 60g of water at a bath ratio of 1:30, add cationic etherification agent ( 3-chloro-2-hydroxypropyltrimethylammonium chloride or 2,3-epoxypropyltrimethylammonium chloride) 50g / L, sodium hydroxide 15g / L and JFC1g / L, heat up to 80°C , stirred continuously, kept warm for 40 minutes, then cooled to 30°C, dehydrated, rinsed with clean water, dehydrated, dried, and used as the fabric to be dyed.

[0038] Dyeing: Take 2g of the fabric to be dyed, and prepare the dye solution at a bath ratio of 1:40, add reactive red B-3BF, reactive orange-2RLN or Megafix yellow B-4GLN 1% (percentage relative to the quality of the fabric to be dyed), and add O 1g / L, JFC 1g / L; dyeing temperature 80°C, dyeing time 30min.

[0039] The specific dyeing process is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com