Crank lubricating filtering device

A technology of filtering device and lubricating oil, which is applied in the installation/connection of lubricant purification device, lubricating parts, pressure lubricant, etc., can solve the problem of increasing the filtering capacity of the filter 4, the poor universality of the filter 4, and the limitation of and other problems, to achieve the effect of increasing the filtration volume, improving the wide applicability, and improving the lubrication function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

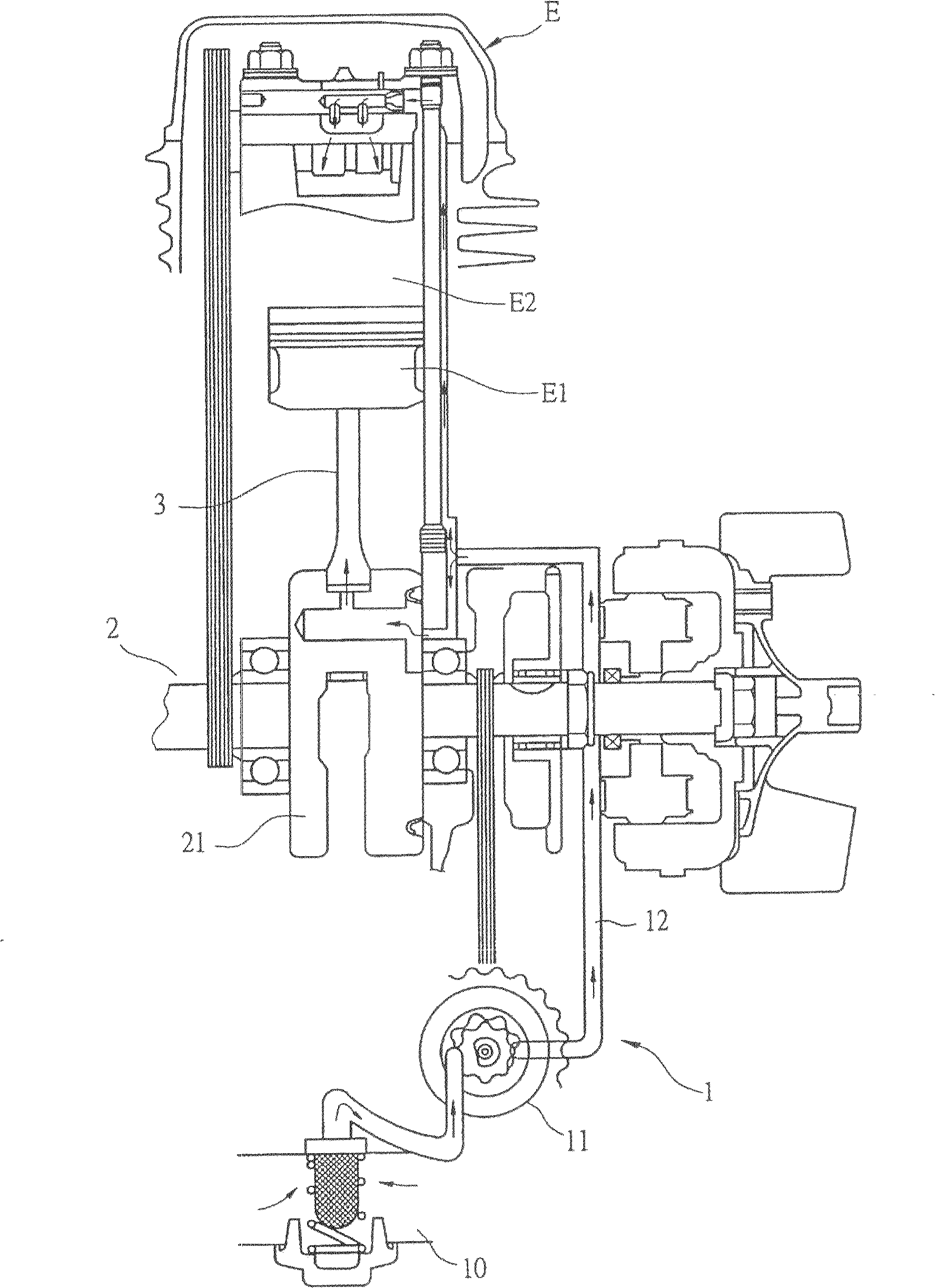

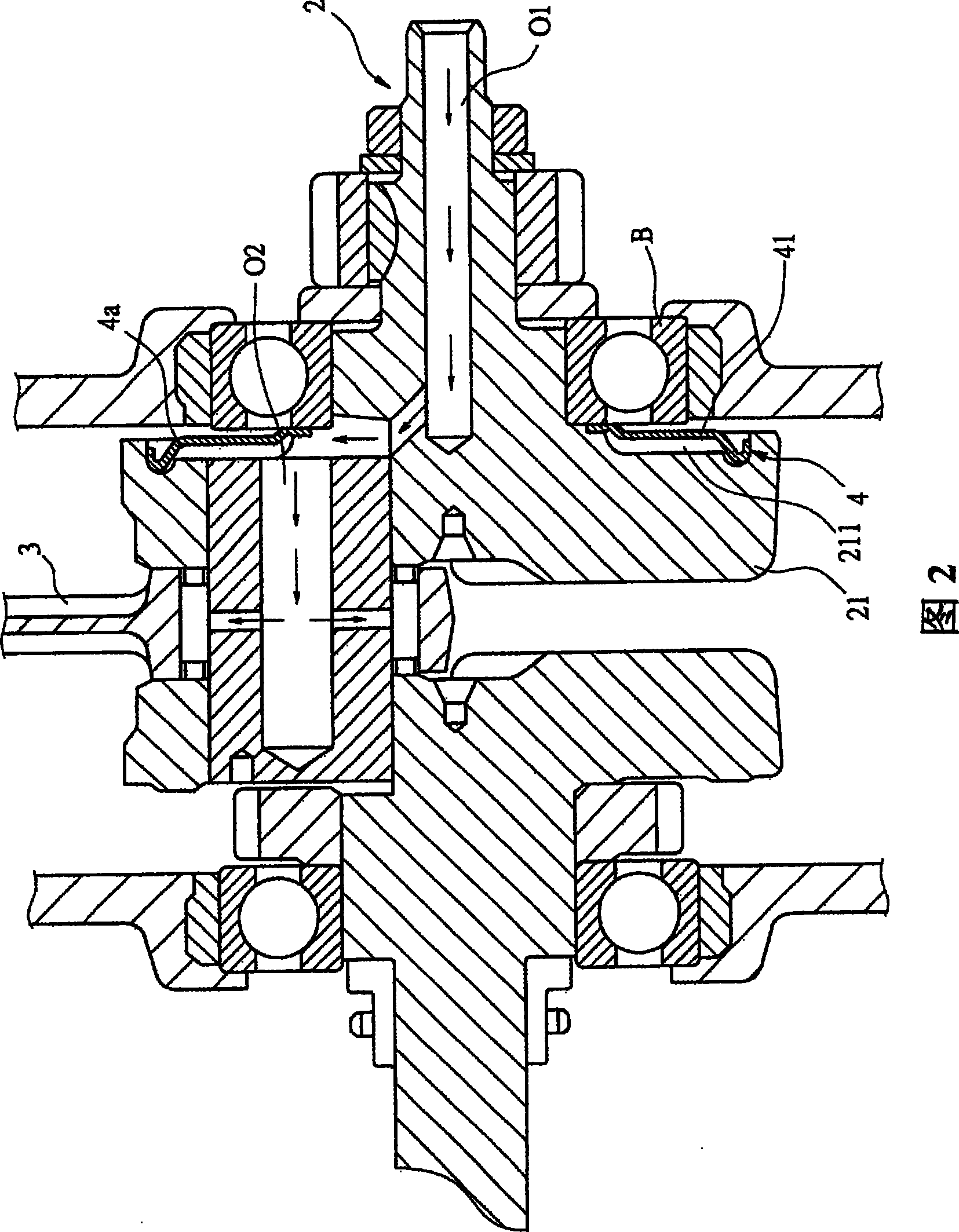

[0025] In order to be easier to understand the structure of the present invention and the effect that can be achieved, the description is as follows in conjunction with the accompanying drawings:

[0026] The present invention is mainly about the filtering device of the crankshaft lubricating oil, other lubricating parts of the engine without modification, so it will not be described in detail. Below, only the part of the present invention will be described in detail, and it will be described first.

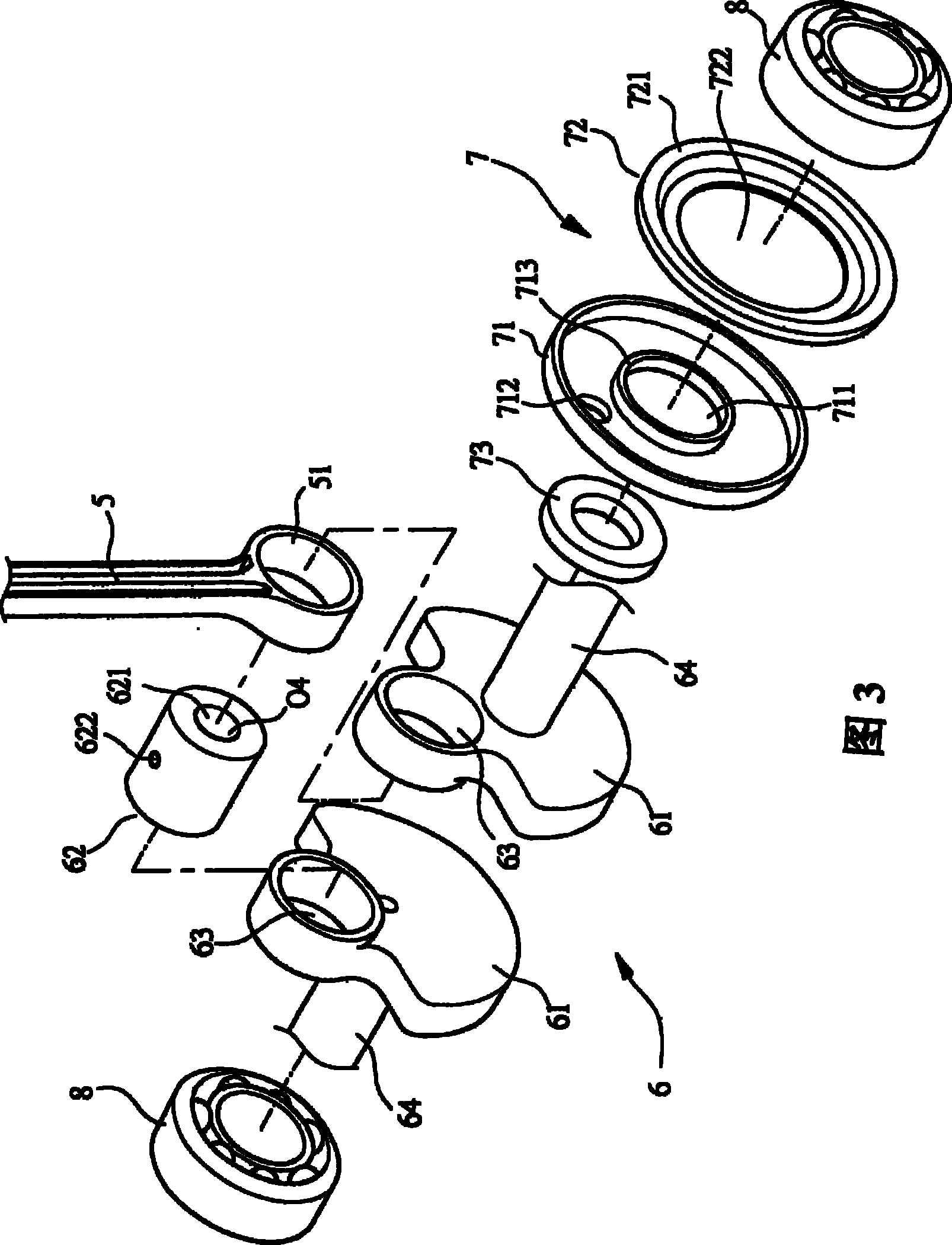

[0027] First, please refer to Figures 3 and 4, the bottom end of the piston connecting rod 5 has a connection hole 51, the connection hole 51 can be used for the penetration of the crank pin 62, and the crank pin 62 is then inserted into the crank connection hole 63, Piston connecting rod 5 promptly gets connected with crankshaft 6 by this, and can drive crankshaft 6 to make circular motion when piston connecting rod 5 burns and does reciprocating motion in engine (not drawing in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com