Stroke-variable engine

An engine and stroke technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of a large number of parts in the valve transmission mechanism, high mechanical noise, and difficulty in achieving high speed, so as to improve durability performance, and the effect of improving installability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

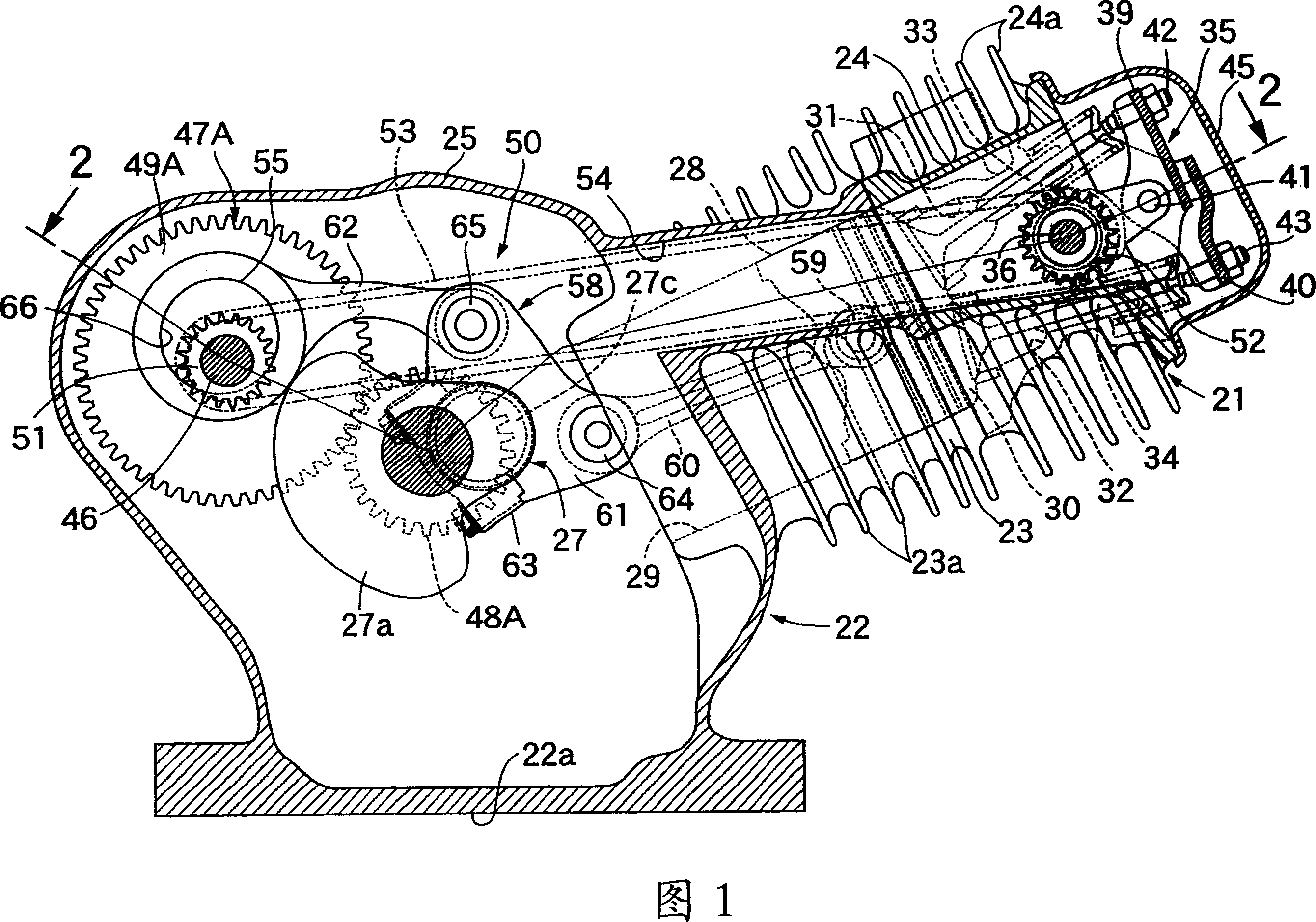

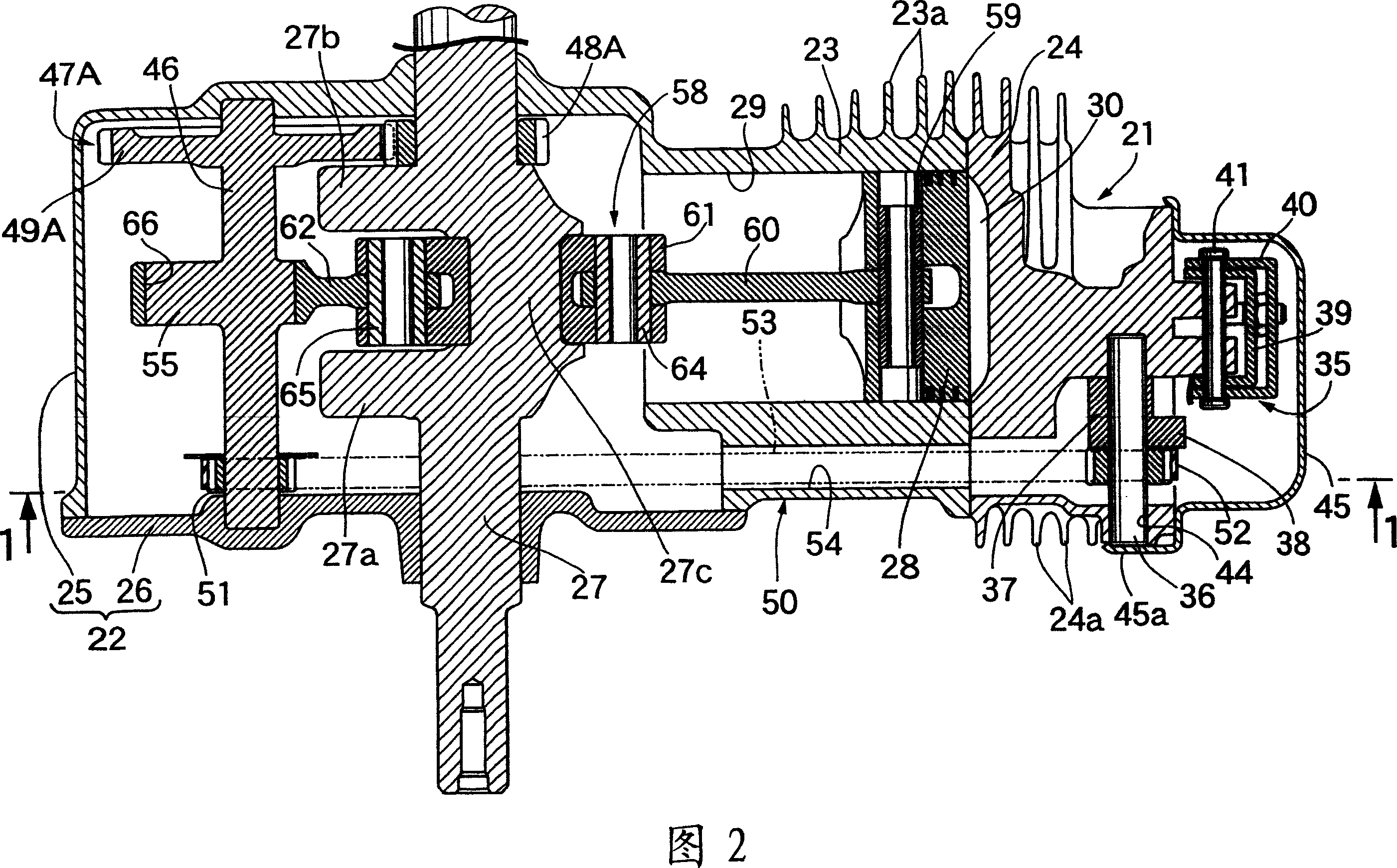

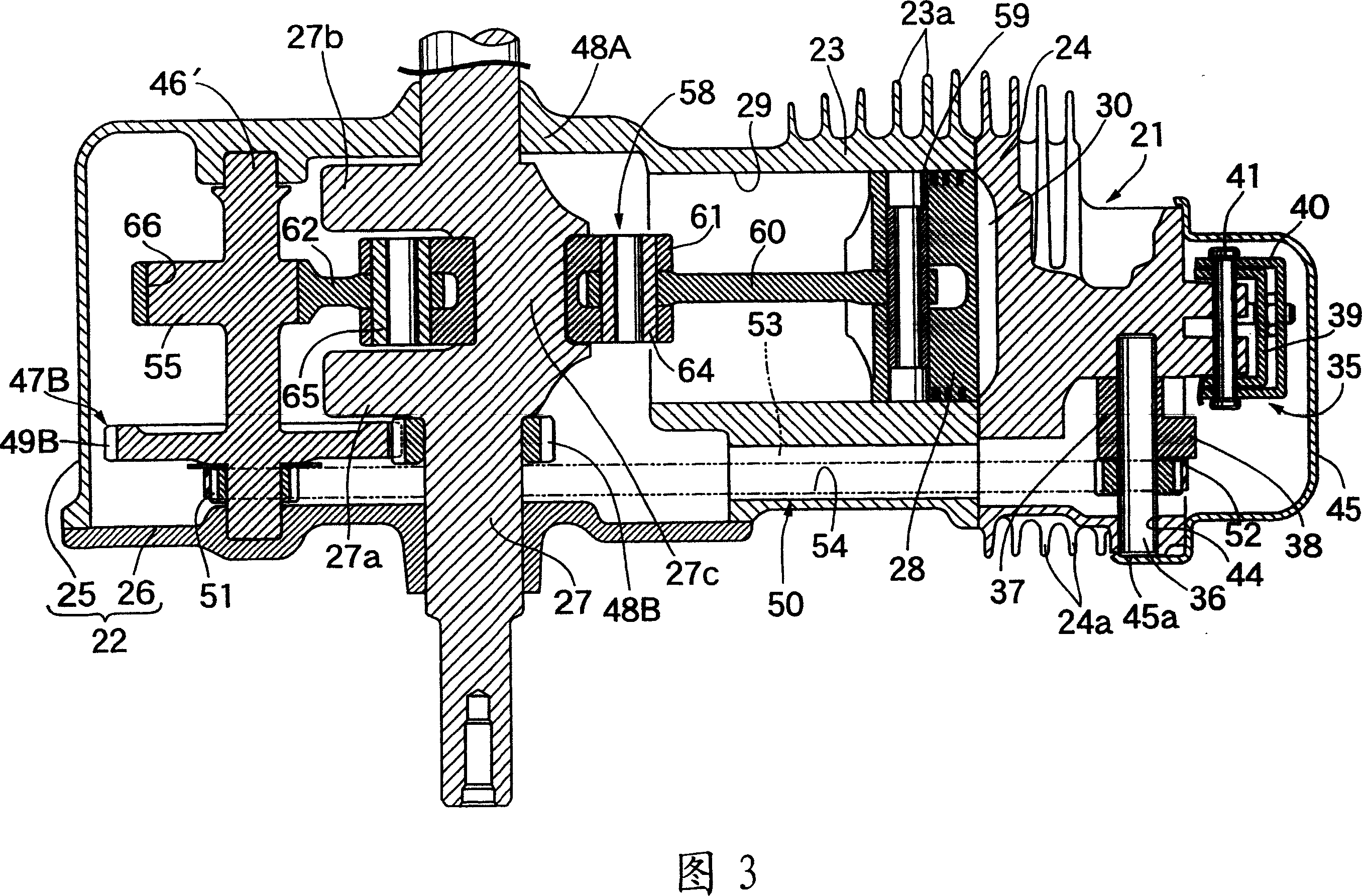

[0021] While referring to Fig. 1 and Fig. 2, the first embodiment of the present invention is described, and this engine is for example utilized in the air-cooled single-cylinder engine in working machine etc., and engine main body 21 is made up of following parts: crankcase 22; 23, which protrudes slightly upward from one side of the crankcase 22; and a cylinder head 24, which is joined to the head of the cylinder block 23, and on the outer sides of the cylinder block 23 and the cylinder head 24, a plurality of air cooling Use fins 23a..., 24a.... In addition, the crankcase 22 is mounted on the engine bed of various working machines by using the mounting surface 22a on the lower surface of the crankcase 22 .

[0022] The crankcase 22 is composed of a case main body 25 which is cast integrally with the cylinder block 23 and which is opened on one side, and a side cover 26 which is joined to the open end of the case main body 25 . The crankshaft 27 integrally includes a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com