Control method for online quality detection

A control method and quality technology, applied in the direction of adaptive control, electrical program control, general control system, etc., can solve problems such as unreasonable quality control plan standards, inability to effectively analyze massive quality inspection data, etc., and achieve early warning of process abnormalities and intelligent diagnosis, the effect of reasonable quality control plan standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

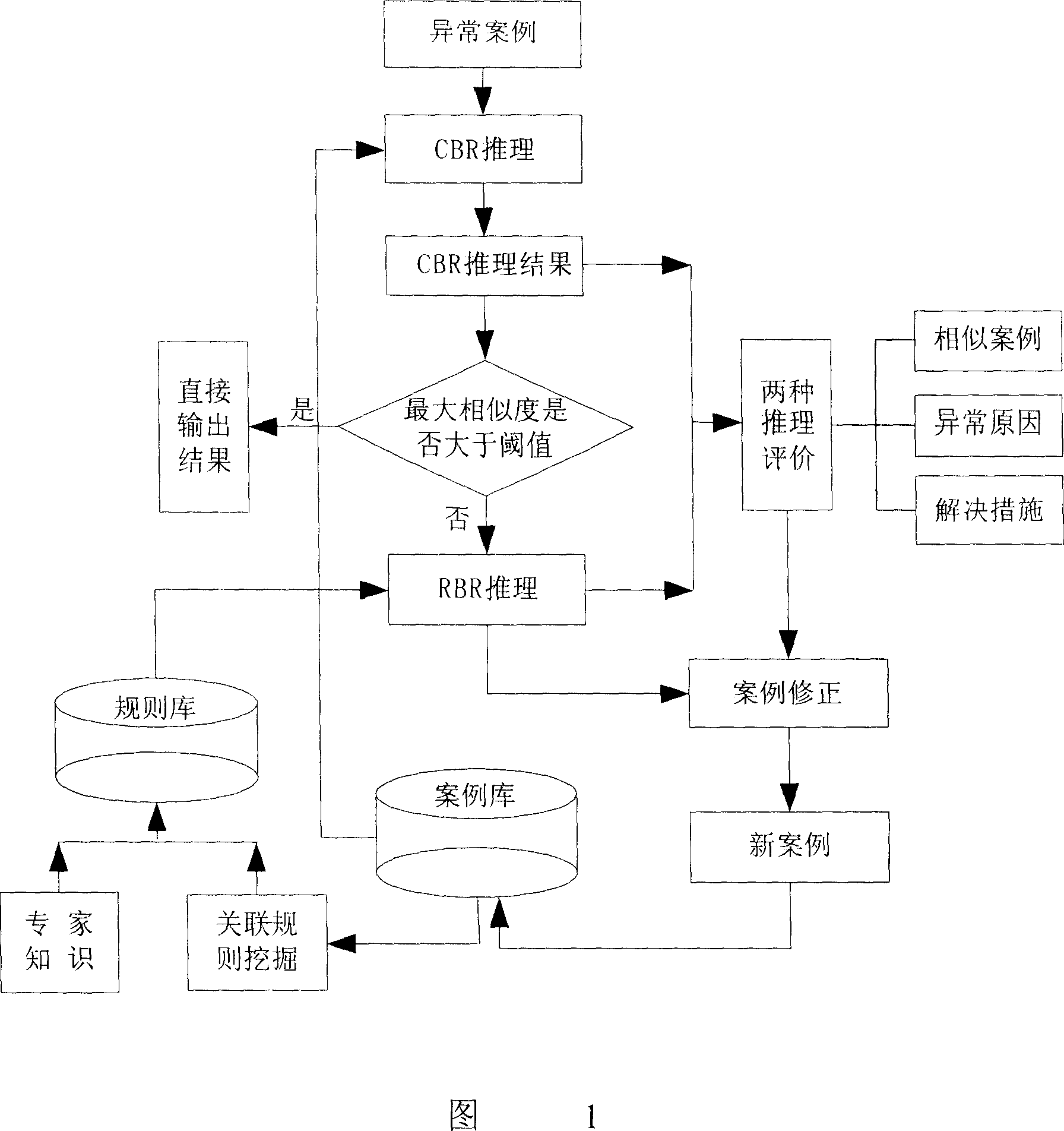

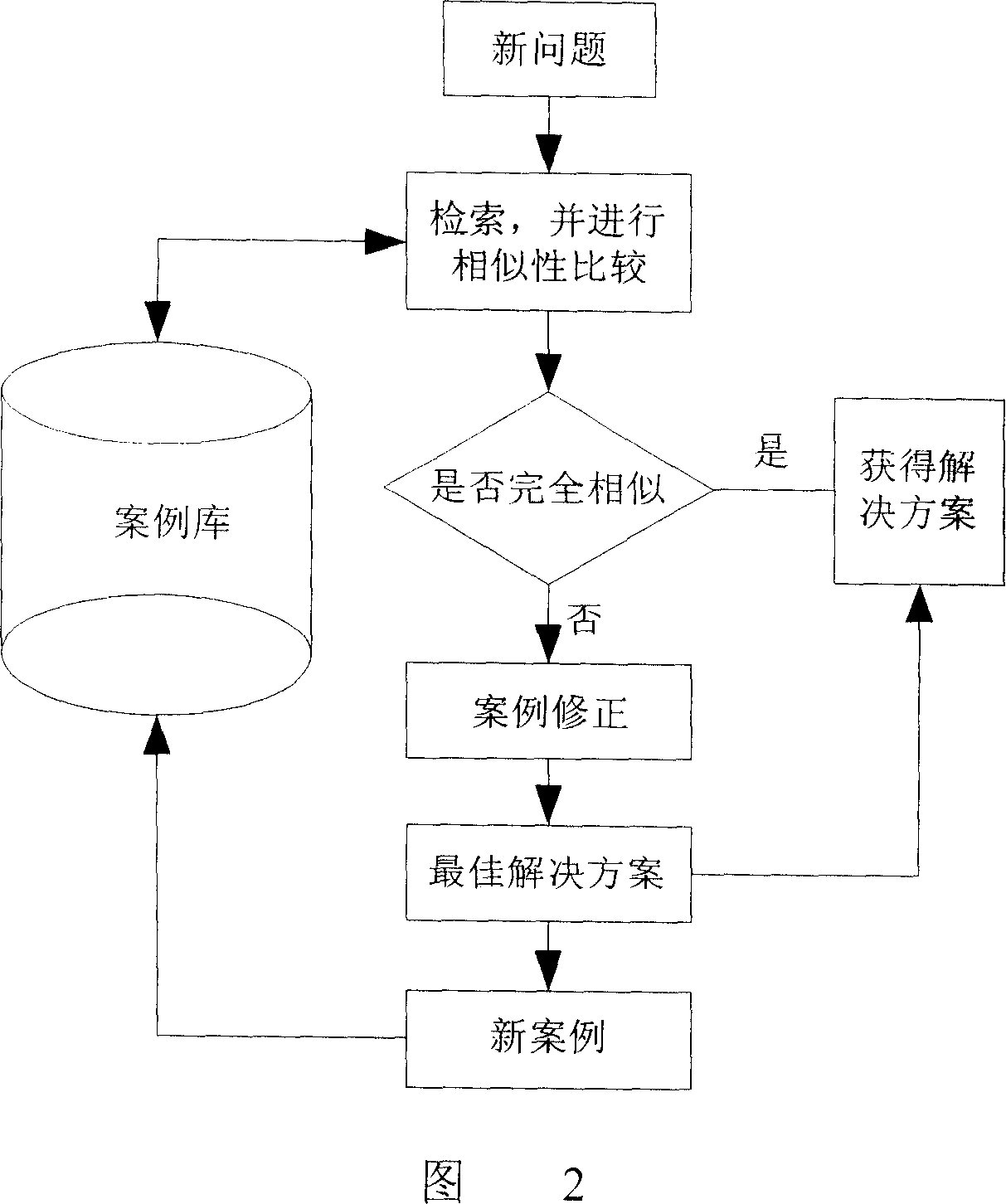

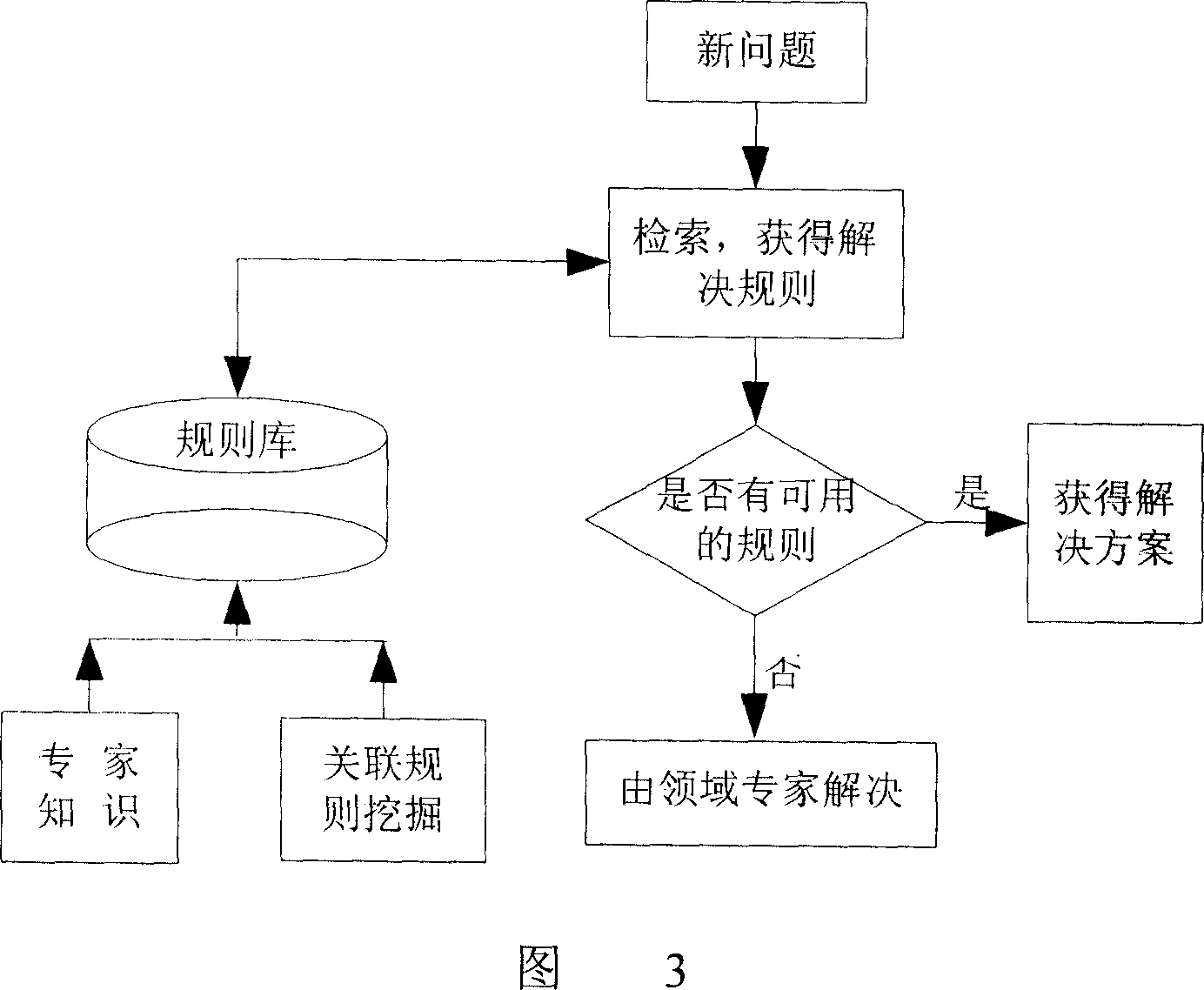

[0035] With reference to Fig. 1, Fig. 2, Fig. 3, a kind of control method of online quality detection, described control method comprises the following steps:

[0036] (1) Establish a case base and a rule base: In the case base, record the abnormal cases, abnormal causes and solutions for each online quality control process, and decompose the characteristic attributes of each case; in the rule base, through expert knowledge and Association rule mining establishes rules for various cases;

[0037] (2) In the process of product online quality inspection, abnormal cases are found;

[0038] (3), abnormal diagnosis:

[0039] (3.1) Decompose the current abnormal case into characteristic attributes, and compare it with the existing cases in the case library:

[0040] The nearest neighbor method is used to calculate the similarity between two cases, and the calculation formula is shown in formula (1):

[0041] NN ( A , ...

Embodiment 2

[0165] Referring to FIG. 1 , FIG. 2 , and FIG. 3 , use the online quality detection control method of Embodiment 1 to detect abnormal motor quality cases.

[0166] Fault history: On October 22, 2004, in the motor product inspection workshop, the no-load current Io of a certain type of Y802-2 motor was detected to be normal, and the no-load loss Po was normal, but the short-circuit current Id was too small and the short-circuit power consumption Pd was too large symptoms.

[0167] Cause of failure: Through analysis and testing, it is found that the rotor resistance is too large. Check the motor rotor and find that the rotor is defective in cast aluminum.

[0168] Measures to be taken: (1) replace the motor rotor; (2) strengthen the quality inspection of the rotor casting.

[0169] First, analyze the failure process of the above case, and the following information can be extracted:

[0170] Motor model: Y802-2

[0171] No-load current Io: normal

[0172] No-load loss Po: nor...

Embodiment 3

[0186] Referring to Figure 1, Figure 2, and Figure 3, use the online quality detection control method of Example 1 to detect abnormal motor quality cases.

[0187]Fault process: In the processing workshop of the motor spindle, the machine tool model is C6132, and the speed is 1200r / min. A certain type of motor spindle is D203, the material is A3, and the shaft diameter is (φ20±0.005). It is found that the points of the spindle measurement control chart often show abnormalities. The abnormal phenomena are: the points fall outside the control limit, and there is a large offset between the center line and the specification center.

[0188] Cause analysis: first adjust the tooling to ensure that the center line coincides with the specification center. After the adjustment, it was found that there were still many out-of-boundary points. Finally, it was analyzed that the precision of the main shaft of the machine tool could not meet the processing requirements. It can be seen that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com