Method of forming circuit pattern on printed circuit board

A printed circuit board, circuit pattern technology, applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve problems such as short circuit, error, non-uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

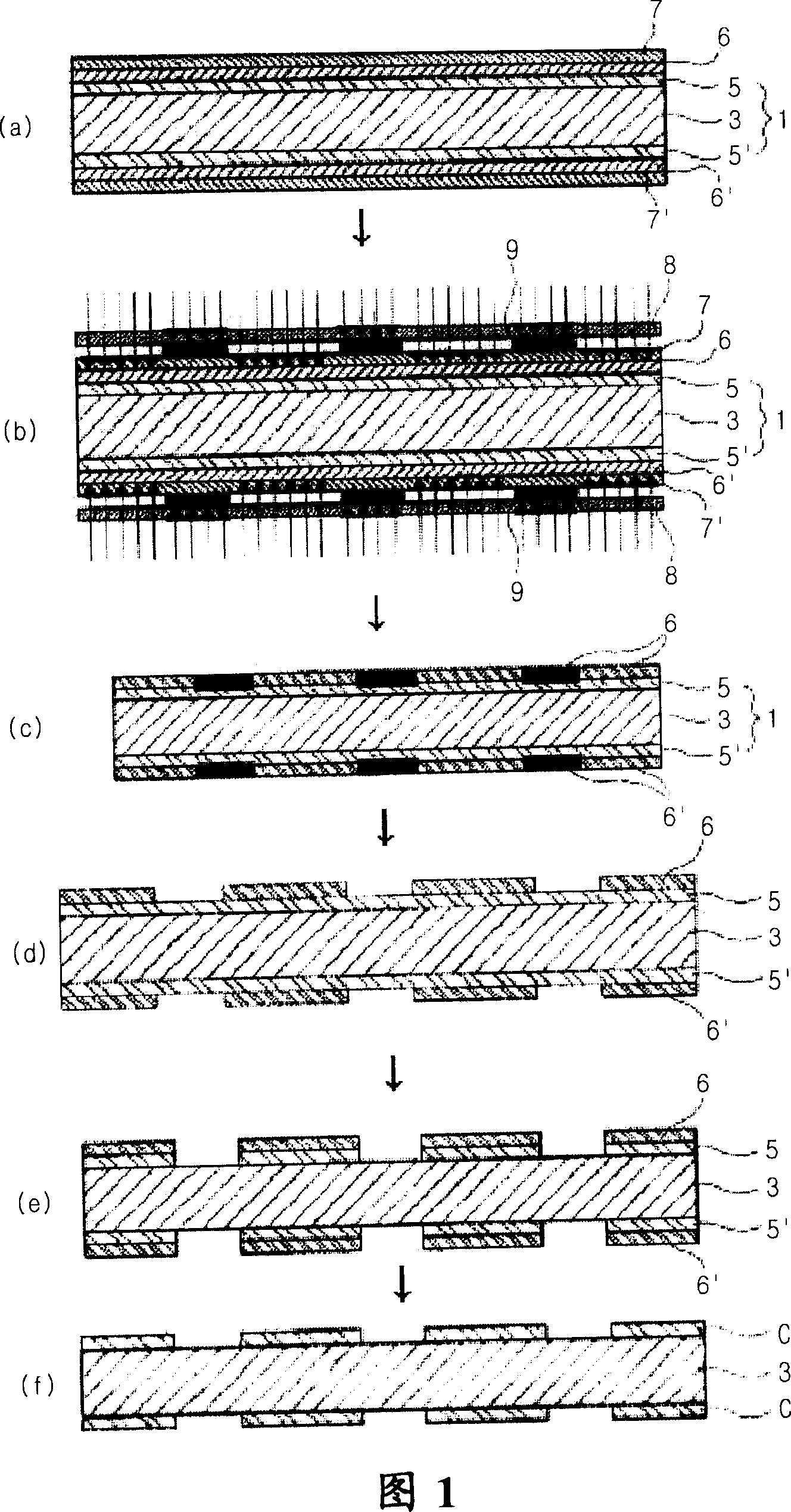

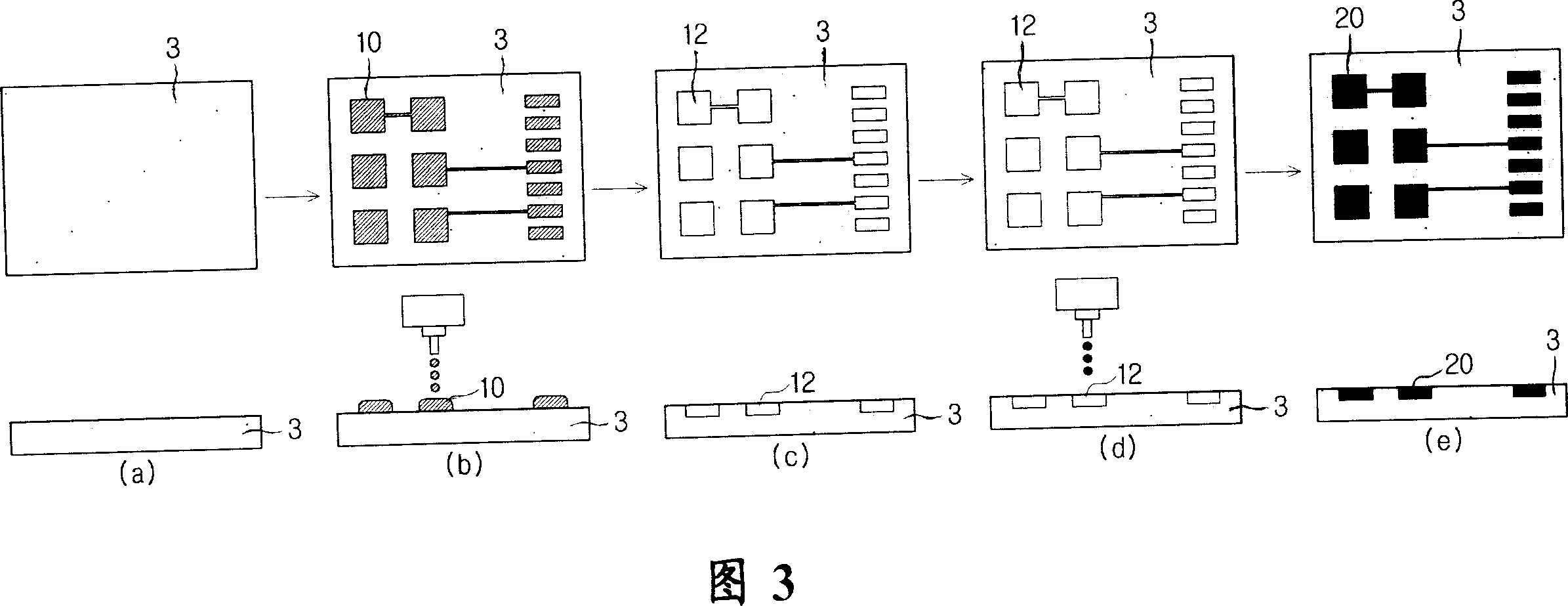

[0030] Hereinafter, embodiments of the present invention will be described in more detail with reference to the accompanying drawings. In the description with reference to the drawings, those same or corresponding components are given the same reference numerals regardless of whether the figure numbers are the same, and redundant explanations are omitted.

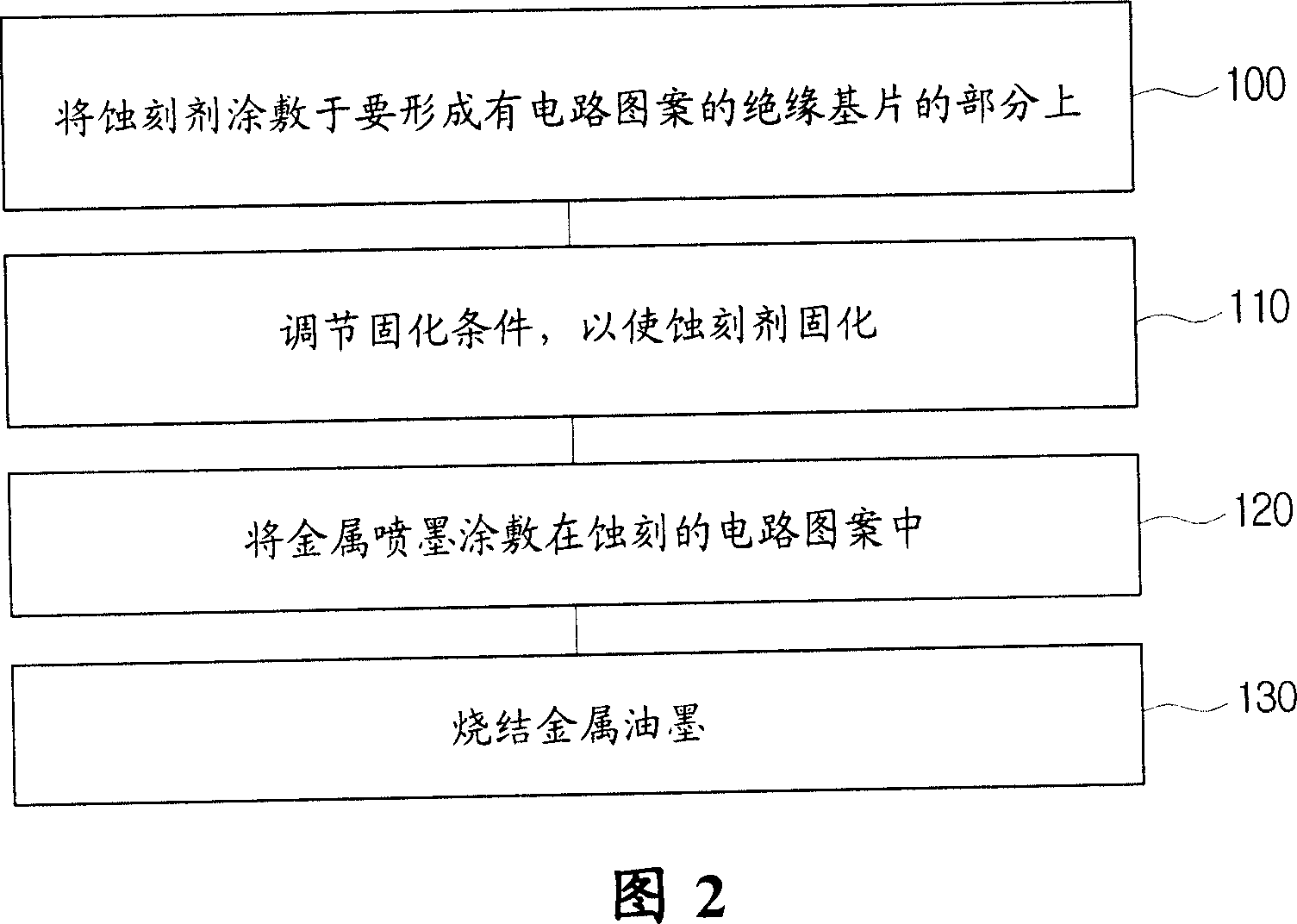

[0031] FIG. 2 shows a flowchart of a process of forming a circuit pattern on a printed circuit board according to an embodiment of the present invention.

[0032] The present invention is characterized by a method of forming a circuit pattern on a printed circuit board, wherein processes such as plating, exposure, and etching (typically time-consuming and expensive circuit patterning processes) are eliminated, and by The printing method sprays etchant and metal ink to form circuit patterns to provide fine patterns and realize pattern width adjustment.

[0033] To this end, an etchant is first applied (100) on a portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com