Peeling and kernel removing machine for lychee

A core peeling machine and litchi technology, applied in the field of litchi peeling and peeling machine, can solve the problems of increased processing cost, high pulp loss rate, low work efficiency, etc., and achieves strong reliability and stability, low processing loss rate, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

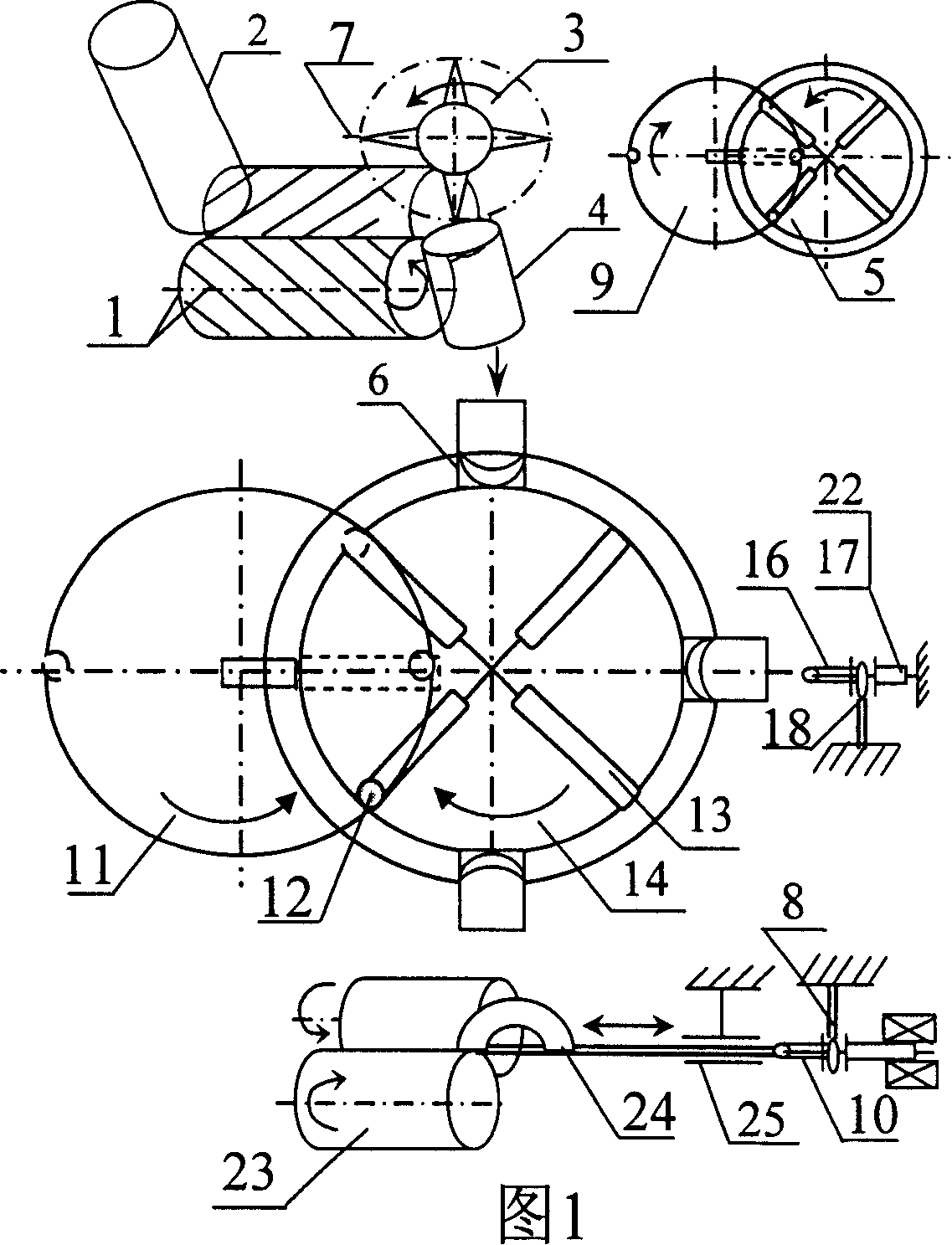

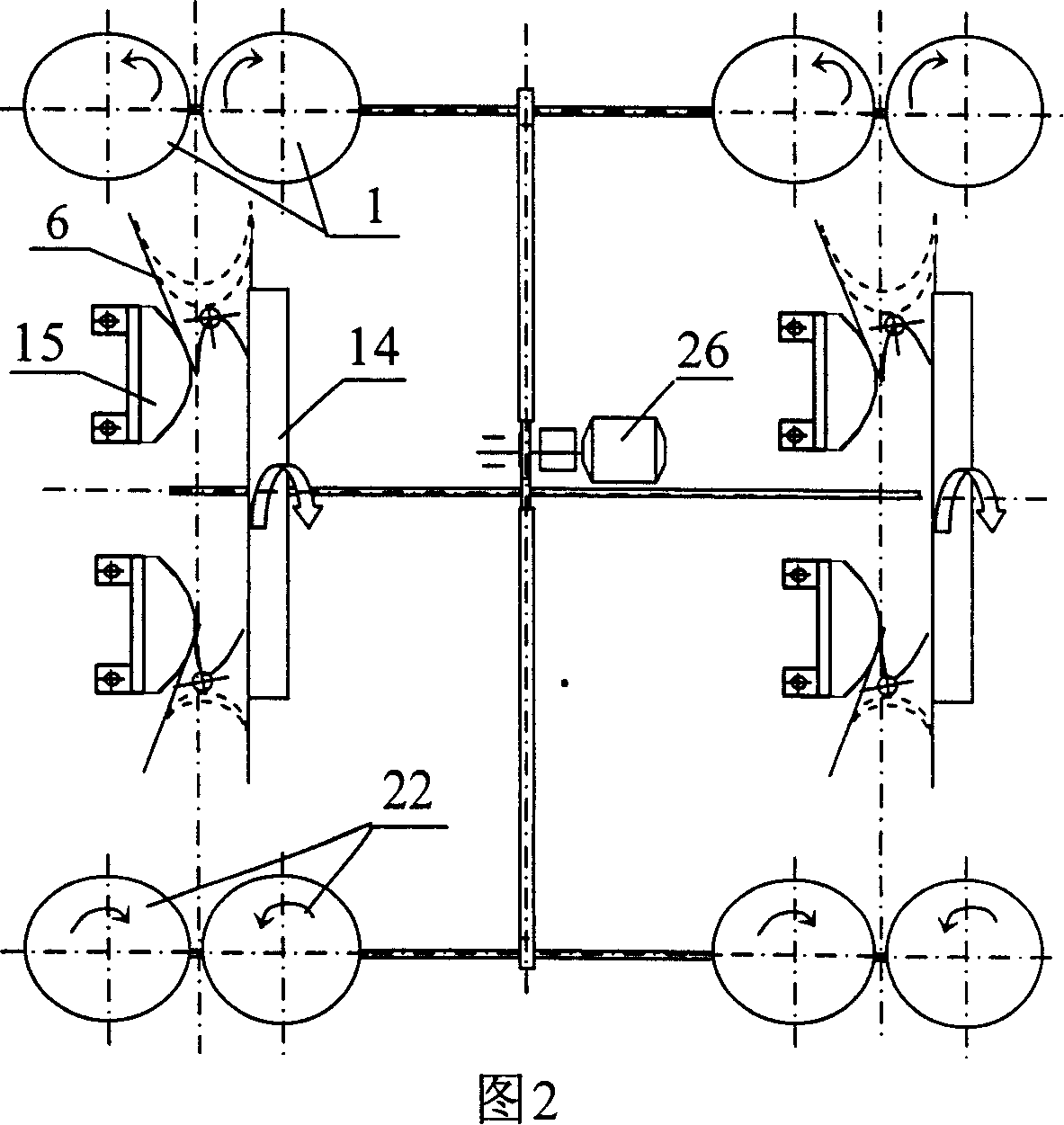

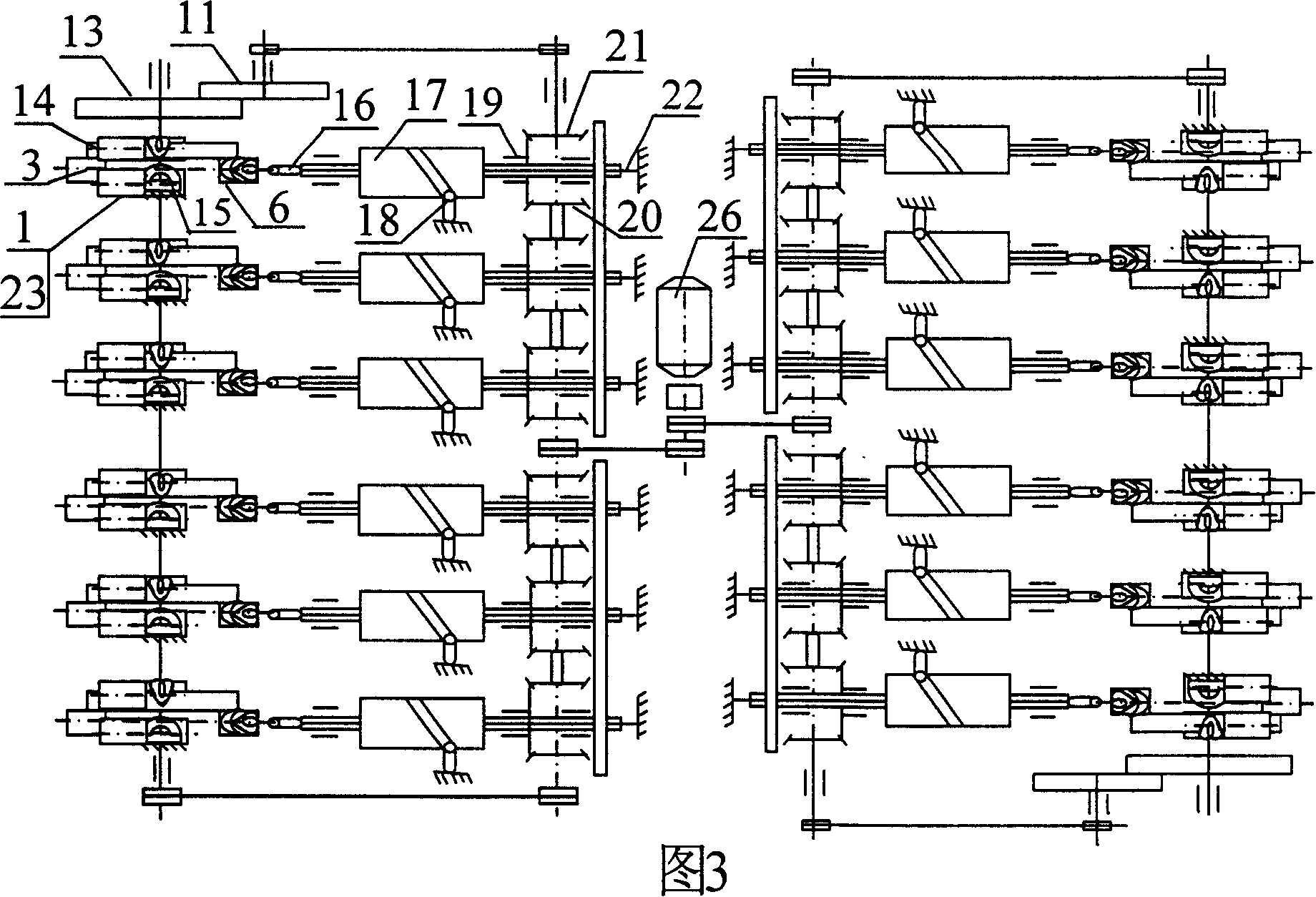

[0027]As shown in Figure 1, the lychee core removal and shelling machine includes a feed positioning mechanism, a core removal mechanism, a peeling mechanism and a driving device; the feed positioning mechanism is arranged on the top and includes a pair of feed rollers 1, Material receiving pipe 2, discharge wheel 3, feeding conduit 4, shell breaking knife 7, dial 9 and outer sheave 5, material receiving pipe 2 is located above the side of feeding roller 1, and is installed on the same root as outer sheave 5 The discharge wheel 3 on the shaft is located above the other side of the feed roller 1, the feed conduit 4 is located below the other side of the feed roller 1, and the shell breaking knife 7 is embedded in the outer circular end face of the discharge wheel 3; The nuclear mechanism is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com