Multi-pipe composite reacting apparatus

A combined reaction and multi-tube technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of complex devices, small amount of information, cumbersome operations, etc., and achieve convenient operation, strong versatility, and device integration high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

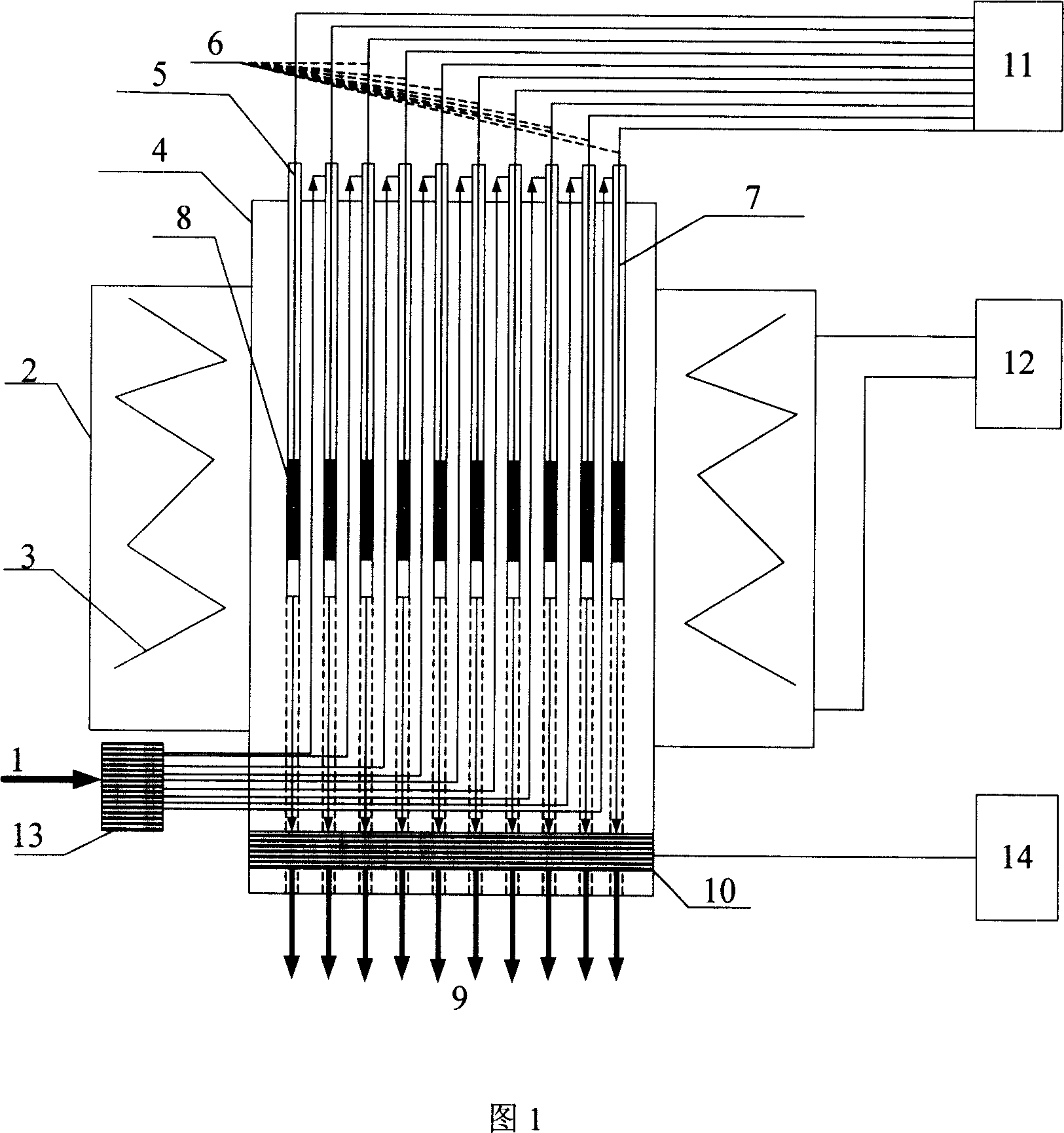

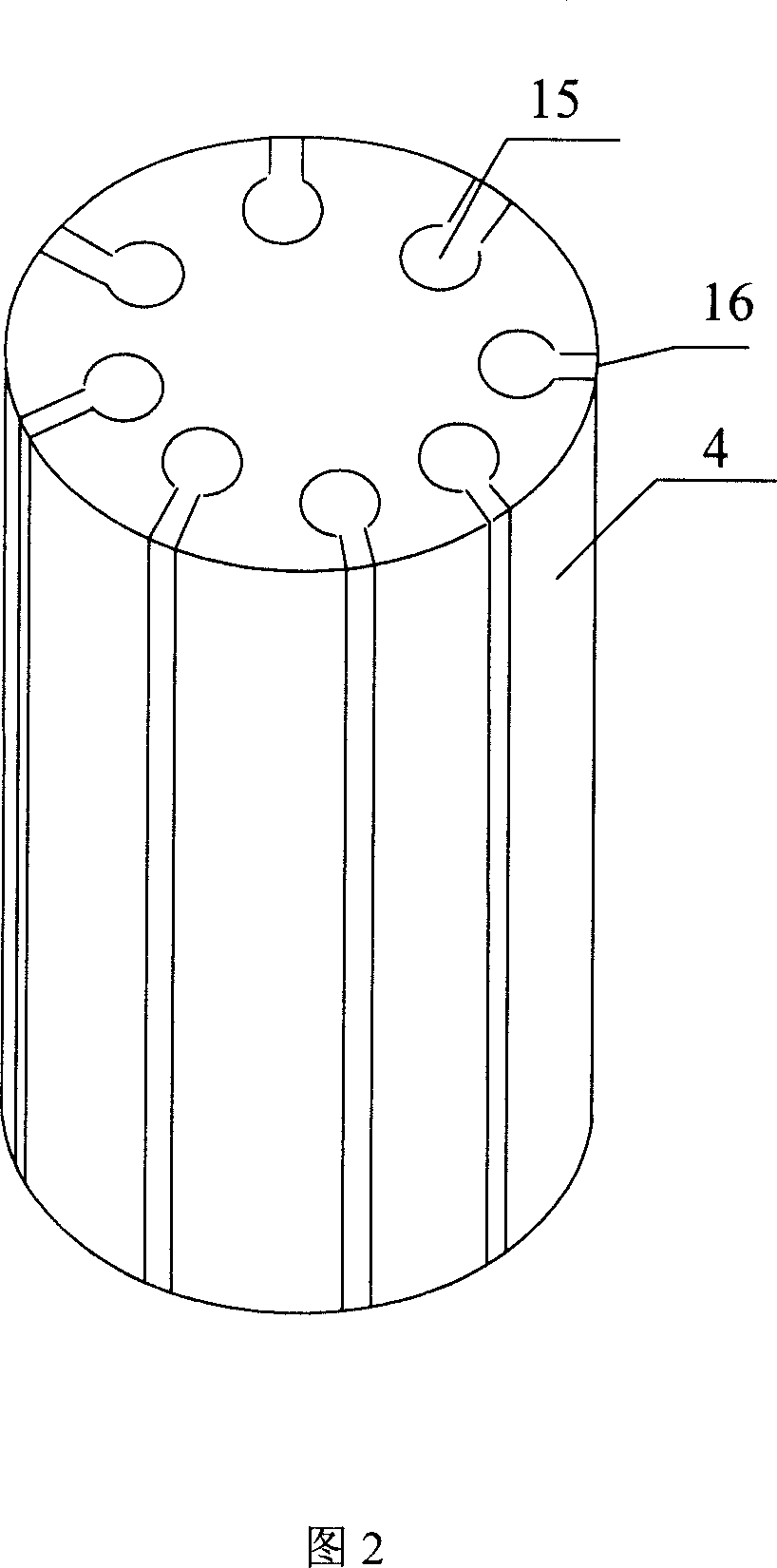

[0019] The main body of the present invention consists of a raw material inlet 1, a heating furnace 2, a heater 3, a heat conducting rod 4, a reaction tube inlet 5, a temperature measuring thermocouple 6, a reaction tube 7, a catalyst bed 8, a product outlet 9, a multi-channel switching valve 10, It consists of a temperature measuring instrument 11, a temperature controller 12, a flow distributor 13, a multi-channel switching valve controller 14, a reaction tube introduction channel 15 and a pipeline connection guide groove 16. The heat conduction rod 4 is located in the hollow area provided inside the heating furnace 2; the heater 3 is located in the heating furnace 2, outside the hollow area; the heat conduction rod 4 is provided with at least two reaction tube introduction channels 15 to place the reaction tube 7, each reaction tube The feed ports of each reaction tube are connected with the flow distributor 13, and the discharge ports of each reaction tube are connected wit...

Embodiment 2

[0022] According to the multi-tubular combined reaction device described in Example 1, only the reaction tubes are 6 reaction tubes. Using 1-butene as feed and ZSM-5 molecular sieve as catalyst, the molar ratio of silicon to aluminum is SiO 2 / Al 2 o 3 At 200, the reaction temperature of each reaction tube is 450°C, 480°C, 500°C, 530°C, 550°C, 580°C, each reactor is filled with the same catalyst, and the weight space velocity is 5 hours-1. Investigate, the yield of ethylene propylene is shown in Table 1 and Table 2.

[0023] Response time, hours

[0024] Response time, hours

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com