Mechanical vapor generating device and method

A steam and mechanical technology, which is applied in the field of mechanical steam generating devices and steam generation in the petroleum industry, can solve problems such as potential safety hazards, achieve the effects of eliminating open flames, convenient operation, and solving potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

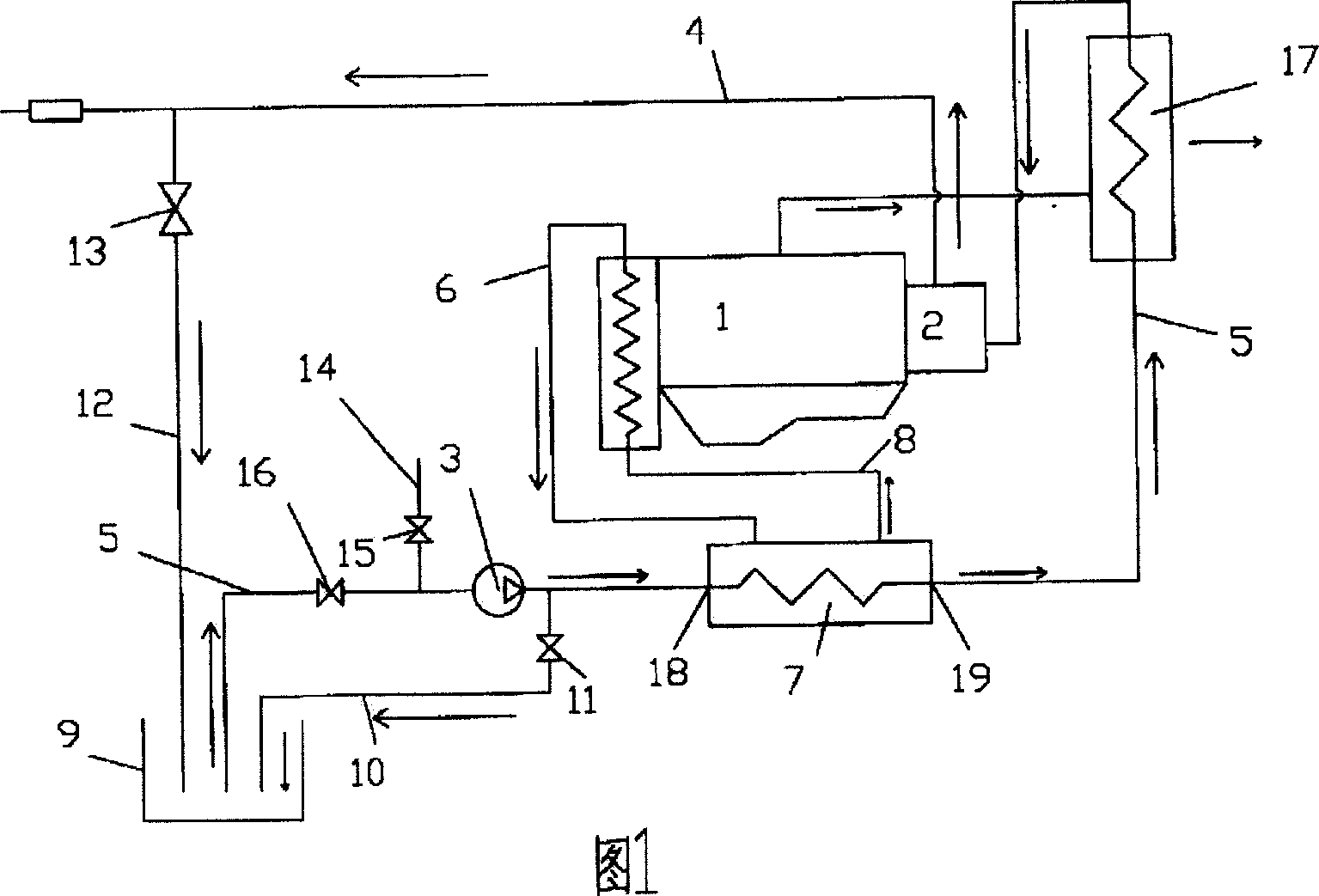

[0027] Embodiment 1, as shown in accompanying drawing 1, this mechanical generation steam device, it comprises engine 1, turbine heater 2 and water pump 3, and the power output shaft of engine 1 is connected with the rotating shaft of turbine heater 2, and turbine heater The inlet of 2 is a water inlet, and the heat output pipe 4 is connected on the heat outlet of the turbo heater 2, and the water inlet pipe 5 is connected on the water inlet, and the water pump 3 is installed on the water inlet pipe 5.

Embodiment 2

[0028] Embodiment 2, as shown in accompanying drawing 1, this mechanical generation steam method is carried out as follows: first cold water is pumped into the coolant heat exchanger 7 of required engine 1 by water pump 3, through primary heat exchange, absorbs engine coolant heat energy; secondly, the hot water after the required primary heat exchange enters the required exhaust heat exchanger of engine 1 to absorb the heat energy of the engine exhaust, and performs secondary heat exchange; and then passes through the above-mentioned required two-stage heat exchange The hot water finally enters the turbo heater, and the high-speed mechanical vortex friction generates heat to make the hot water temperature reach the required temperature, and provides hot water or / and steam through the heat output pipe. Accompanying drawing 1 shows the best embodiment of the method for mechanically generating steam in the present invention, but the non-essential technical features in Embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com