Hall sensor array based steel ropes nondestructive examination method and device

A hall sensor and non-destructive testing technology, applied in the direction of magnetic sensor array, material magnetic variable, etc., can solve the problems of quantitative identification of unfavorable defects, the circumferential distribution of defects that cannot be identified, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Fig. 5 is a schematic flowchart of an embodiment of the non-destructive testing method for steel wire ropes based on Hall sensor arrays in the present invention.

[0032] The detection method comprises the following steps:

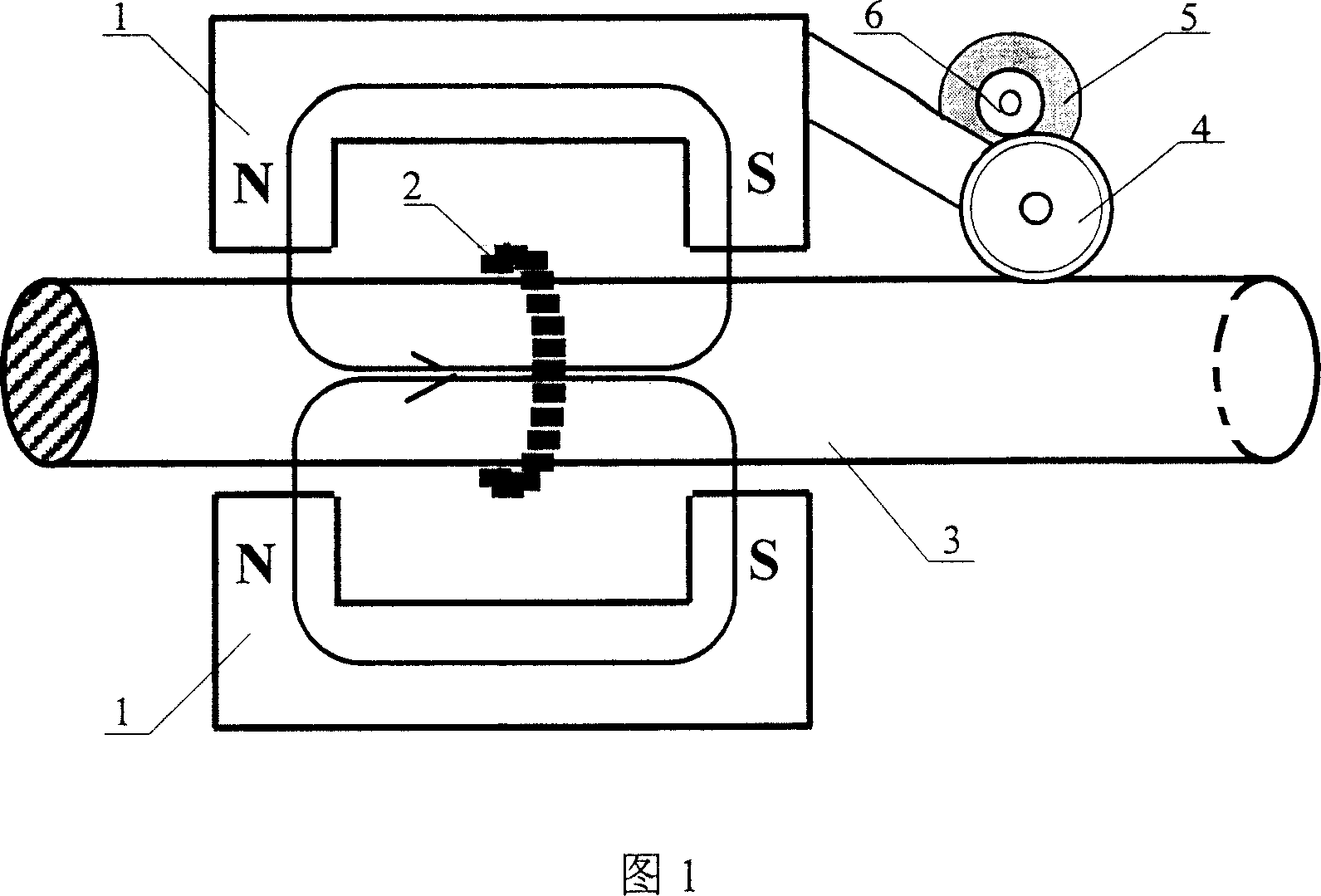

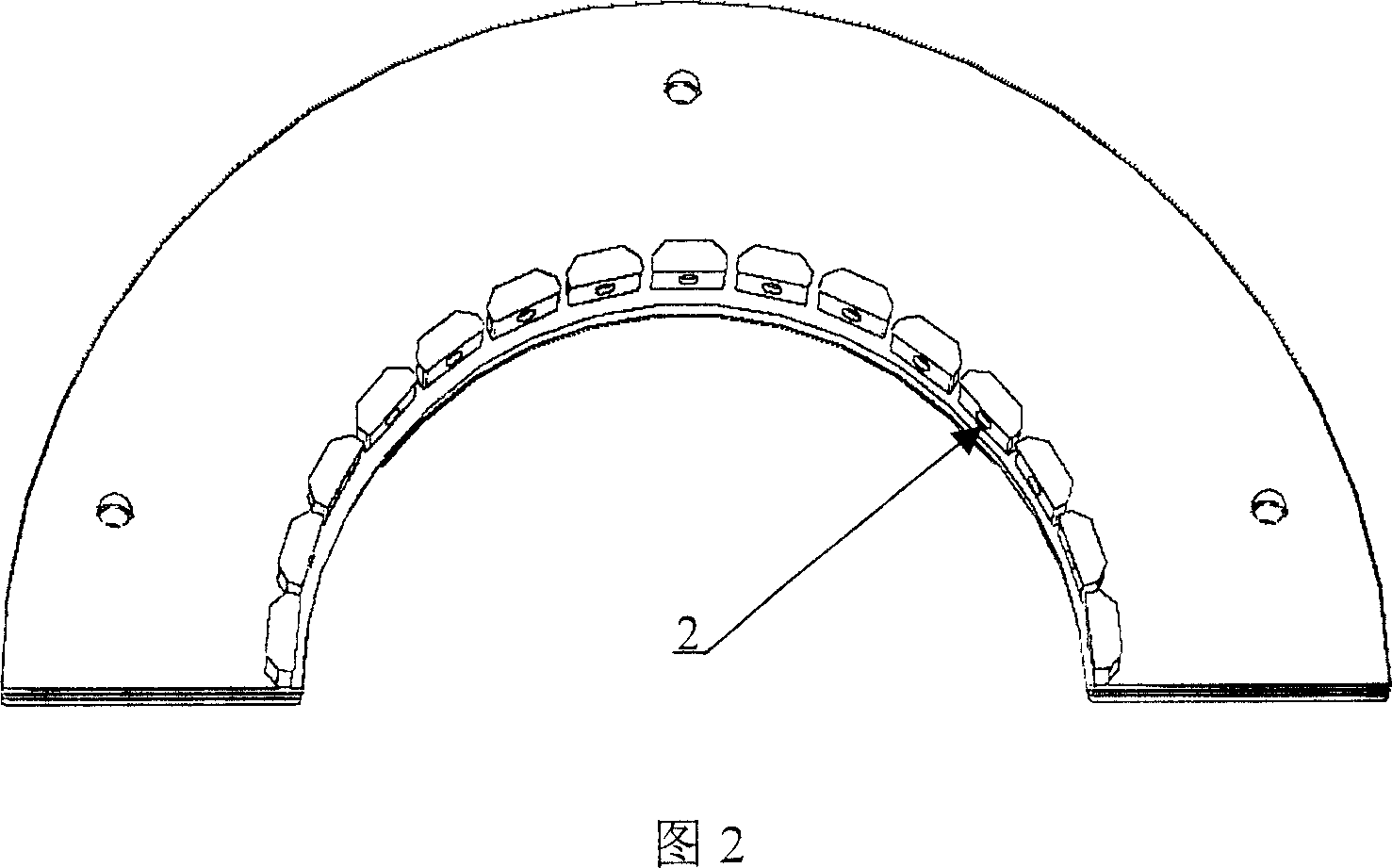

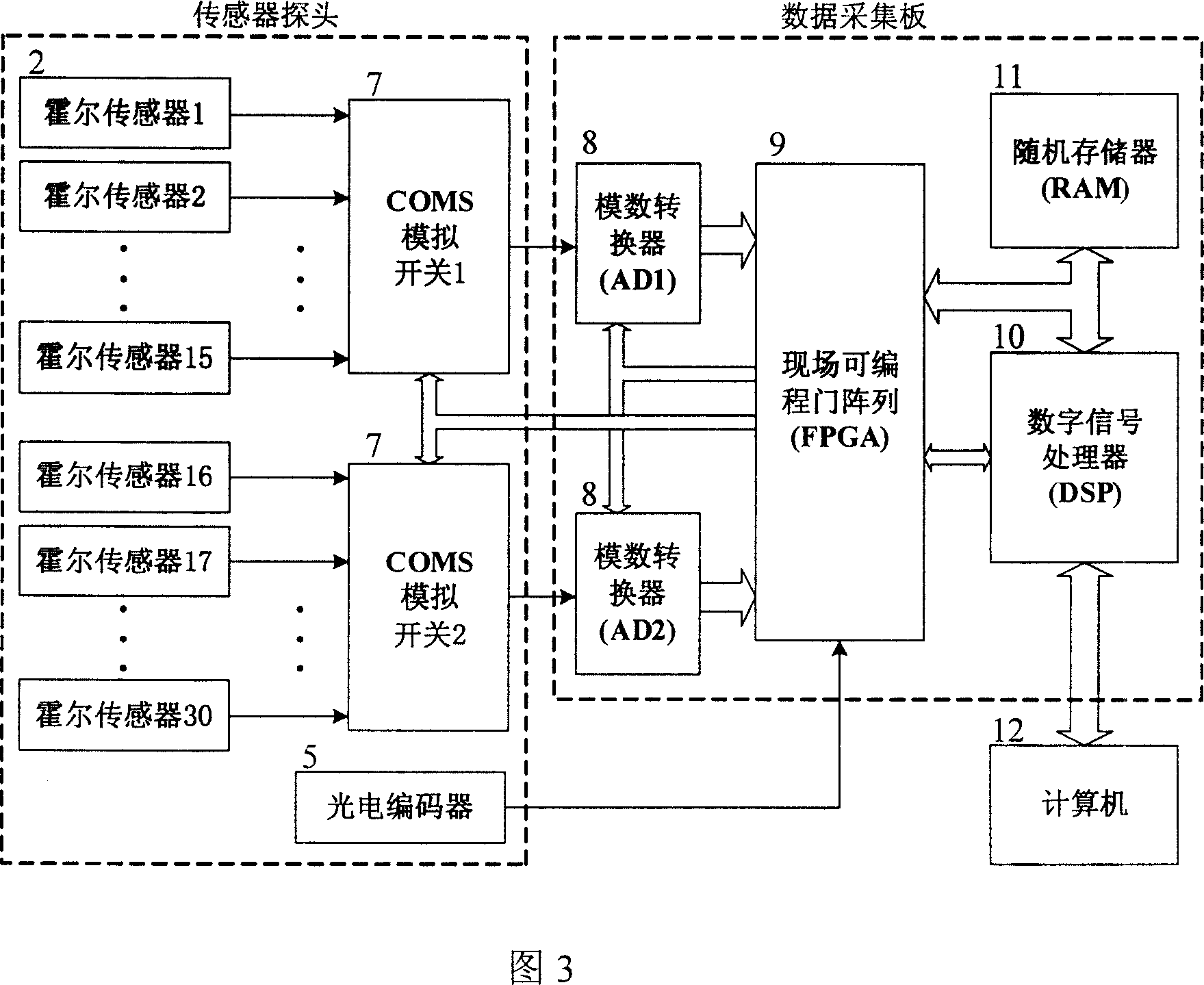

[0033] 1. Make a standard sample of typical defects at the end of the steel wire rope under test without defects, use the permanent magnet excitation mechanism 1 to excite the steel wire rope in the axial direction, and use the Hall sensor array 2 densely distributed on the surface of the steel wire rope to capture the diameter of each typical defect. MFL data;

[0034] 2. In the PC, by adjusting the notch frequency of the notch filter to make it track the spatial frequency of the strand wave of the wire rope, the original data is filtered by the filter;

[0035] 3. The filtered signal is subjected to size normalization and amplitude normalization processing, wherein the size normalization divides the collected two-dimensional signal into matrices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com