Control method for curved-tooth angle gear chamfering

A technology of a spiral bevel gear and a control method, applied in the field of gear processing, can solve problems such as difficult quality assurance, and achieve the effects of long service life, smooth operation and meshing, and easy understanding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

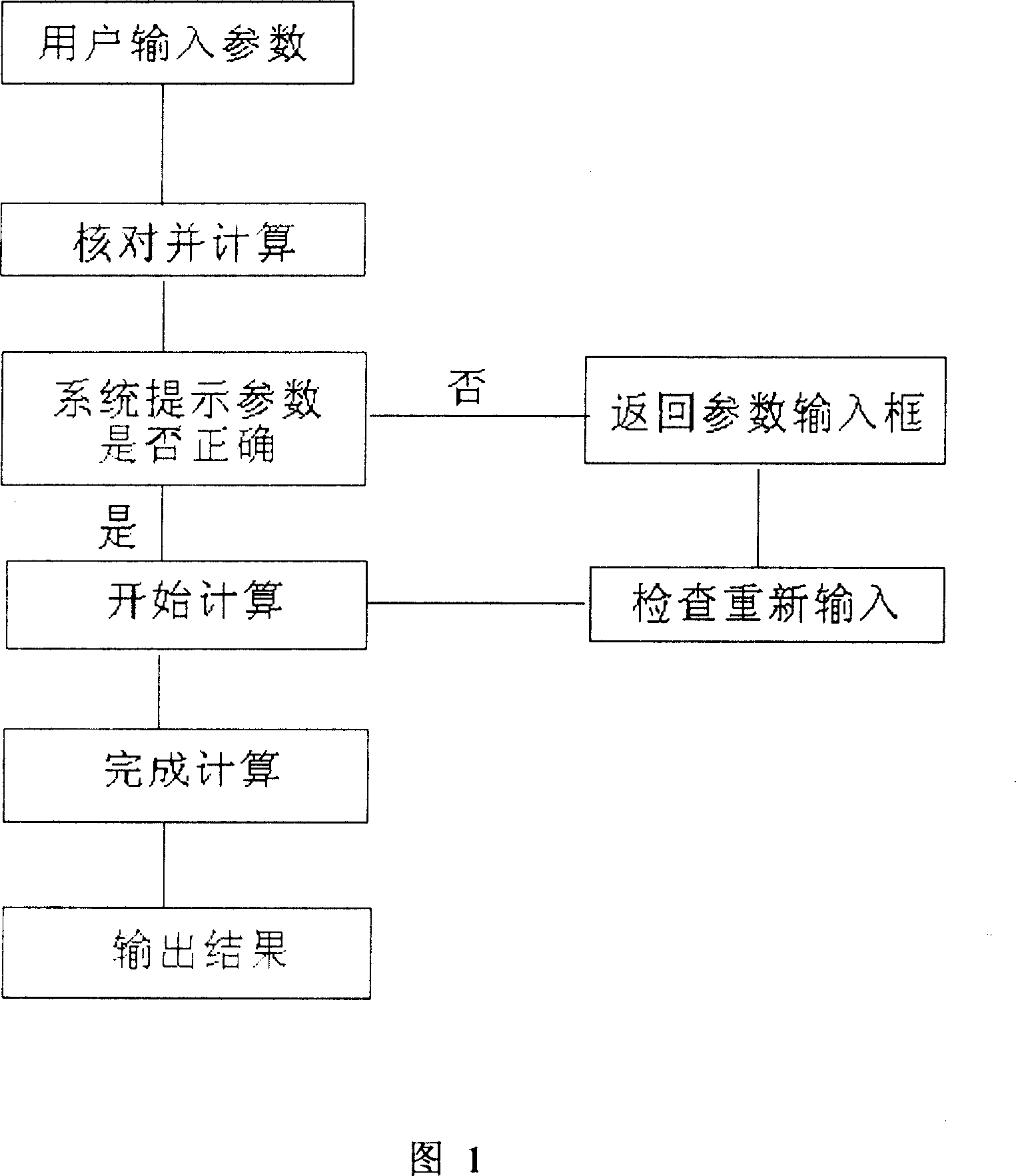

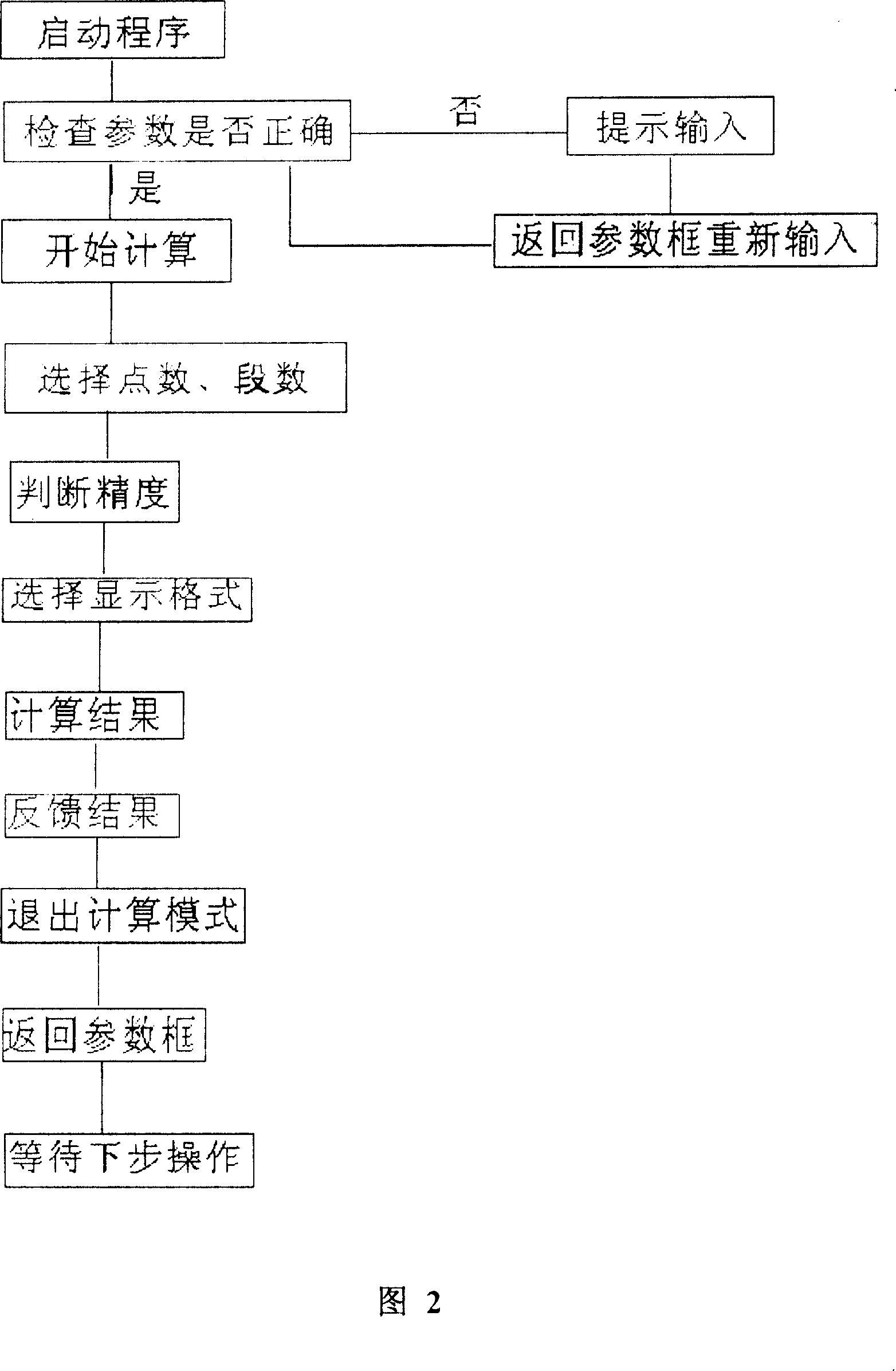

[0026] With reference to accompanying drawing 1 and Fig. 2.

[0027] The method of controlling the chamfering of the spiral bevel gear controls the three-axis linkage machine tool. According to the layout of the chamfering machine tool and the coordinates of the movement, the spiral bevel gear machining calculates and controls the conical positioning tool and the tooth top ridgelines on both sides of the concave and convex tooth grooves, and determines the position between the chamfered workpiece tooth groove and the workpiece spindle of the machine tool The relationship between the tool and the tooth top ridge line on both sides of the concave and convex of the tooth groove is double-touched; the control of the three-axis linkage machine tool for gear chamfering processing is realized.

[0028] Calculation control includes the stage of automatic analysis, the stage of segmented calculation according to the input parameters, the stage of numerical feedback prompt, and the stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com