Optimizing method for forging modeling process

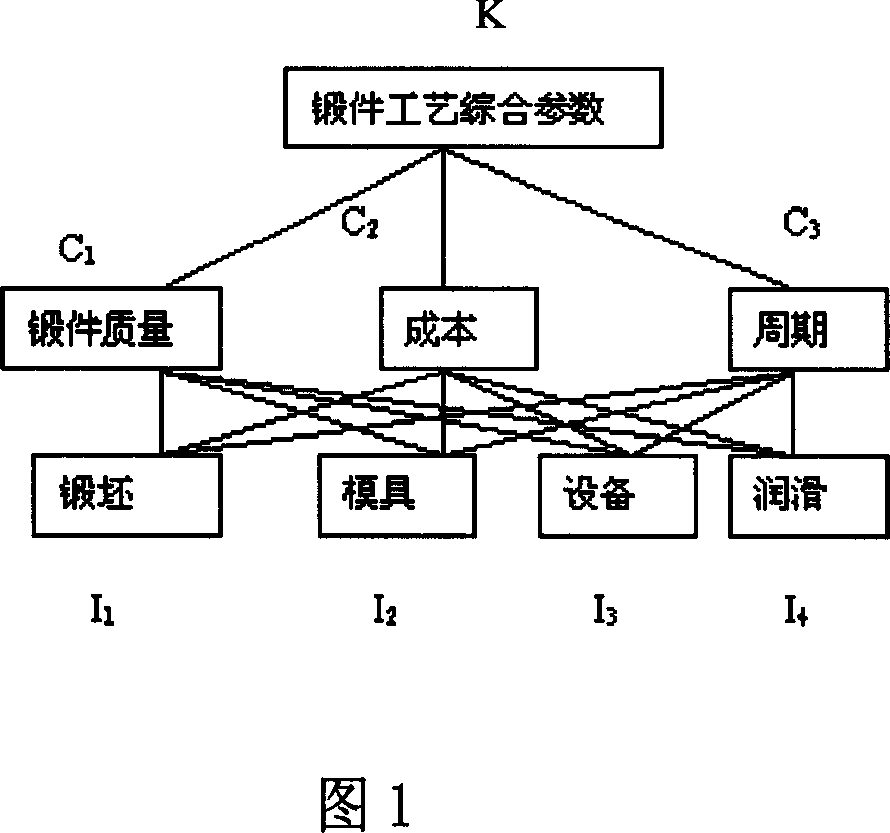

A technology of forming process and optimization method, which is applied in the field of forging, can solve problems such as poor accuracy of forging process optimization and no specific quantification of optimization analysis, and achieve the effects of shortening the design cycle of forging process, saving time, and improving optimization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Optimum Design of Forging Process for a Connecting Rod of a Diesel Engine

[0049] 1. Forging billet design: take connecting rod M d =153Kg, M p =177Kg, δ takes 3.75%, according to a=M d / [(1-δ)M p ], a = 0.898 is obtained.

[0050] 2. Equipment selection: The equipment uses a 5600T screw press, and the actual required deformation force curve of the forging is shown in Figure 2. According to F d =βF e , F e =5600T,F d =5300T, resulting in β=0.95.

[0051] 3. Lubrication and heating process

[0052] When the connecting rod is hot forged, use water-based graphite, spray evenly, and the lubrication coefficient μ is 0.3, press μ p =1.06~0.533μ calculation, get μ p = 0.9.

[0053] 4. Mold

[0054] Through computer numerical simulation, determine the minimum compressive stress p of the die when the forging is fully filled min , Figure 3 is the force diagram of the mold, the stress level is represented by color spots, the displayed value is 712MPa, and ...

Embodiment 2

[0061] Example 2: Optimal design of forging process for rocker arm of a certain diesel engine

[0062] 1. Forging billet design: take rocker arm M d =16.5Kg, M p =20Kg, δ takes 3.75%, according to a=M d / [(1-δ)M p ], a = 0.857 is obtained.

[0063] 2. Equipment selection: The equipment uses a 3500T press. The actual required deformation force curve of the forging is shown in Figure 4. The stress level is represented by color spots, and the displayed value is 700MPa. The maximum compressive stress on the surface of the lower die is also 700MPa. According to F d =βF e , F e =3500T,F d = 3315T, resulting in β = 0.95.

[0064] 3. Lubrication and heating process

[0065] When the rocker arm is hot forged, use water-based graphite, spray evenly, and the lubrication coefficient μ is 0.3, press μ p =1.06~0.533μ calculation, get μ p = 0.9.

[0066] 4. Mold

[0067] Through computer numerical simulation, determine the minimum compressive stress p of the die when the forging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com