LCD driving mechanism for thin film transistor

A liquid crystal display and thin film transistor technology, which is applied in the field of thin film transistor liquid crystal display driving devices, can solve problems such as increasing the power consumption of modules, and achieve the effects of reducing power consumption and avoiding waste of dynamic current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

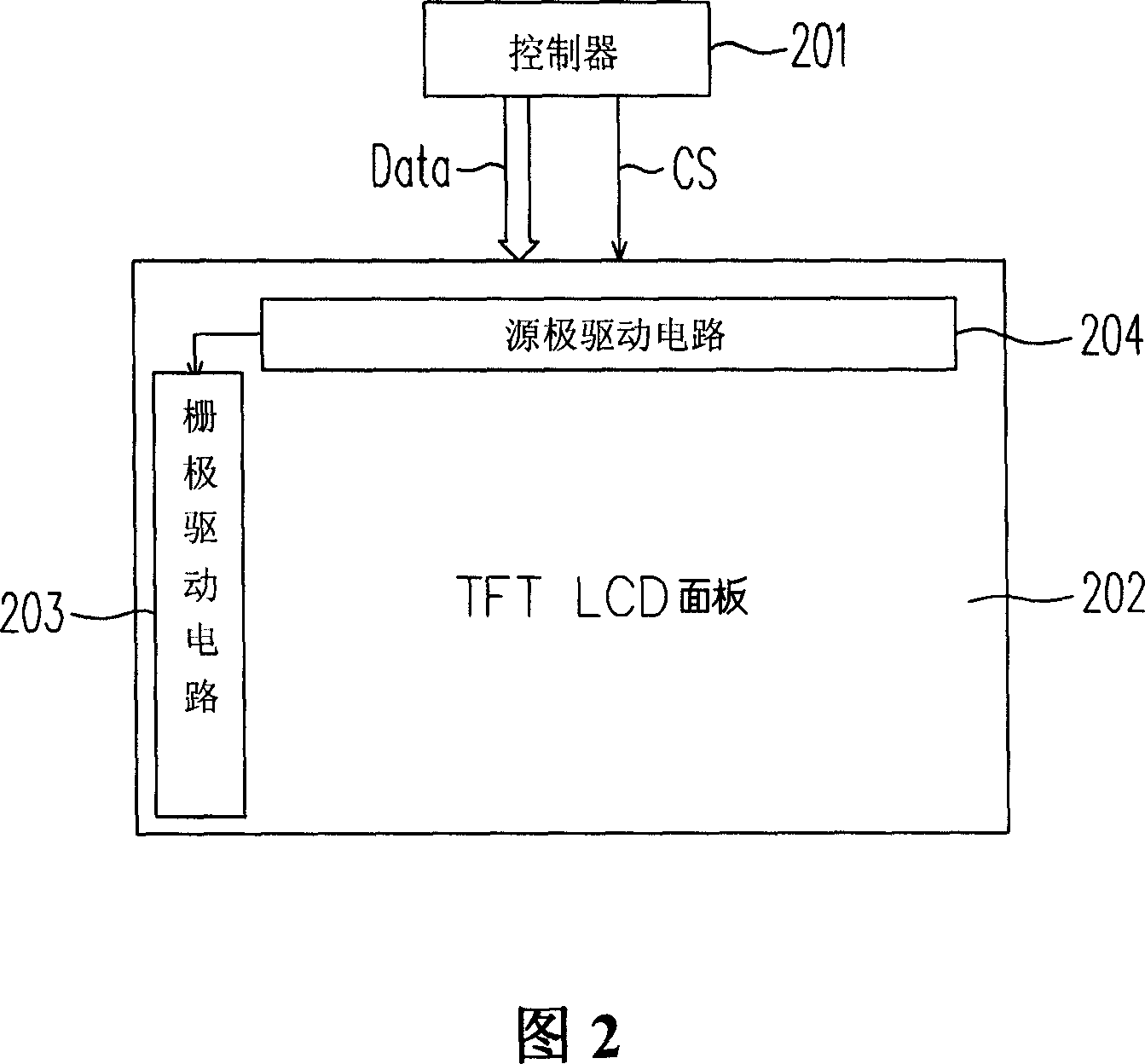

[0039] A thin film transistor liquid crystal display driving device according to an embodiment of the present invention will be described below. Please refer to FIG. 2 first. FIG. 2 is a driving circuit of the liquid crystal display of this embodiment, including a controller 201 , a source driving circuit 204 , and a gate driving circuit 203 .

[0040] In this embodiment, the controller 201 is an application-specific integrated-circuit (ASIC), responsible for outputting the pixel data Data and the control signal CS to the source driving circuit 204 . The control signal CS is a collection of multiple signals, including a start pulse signal (start pulse) and a latch pulse signal (latch pulse), etc. These signals will be described in more detail later.

[0041] The source drive circuit 204 has a plurality of output terminals, and its main function is to convert the pixel data Data from a digital signal to an analog data level according to the latch pulse signal, and then output i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com