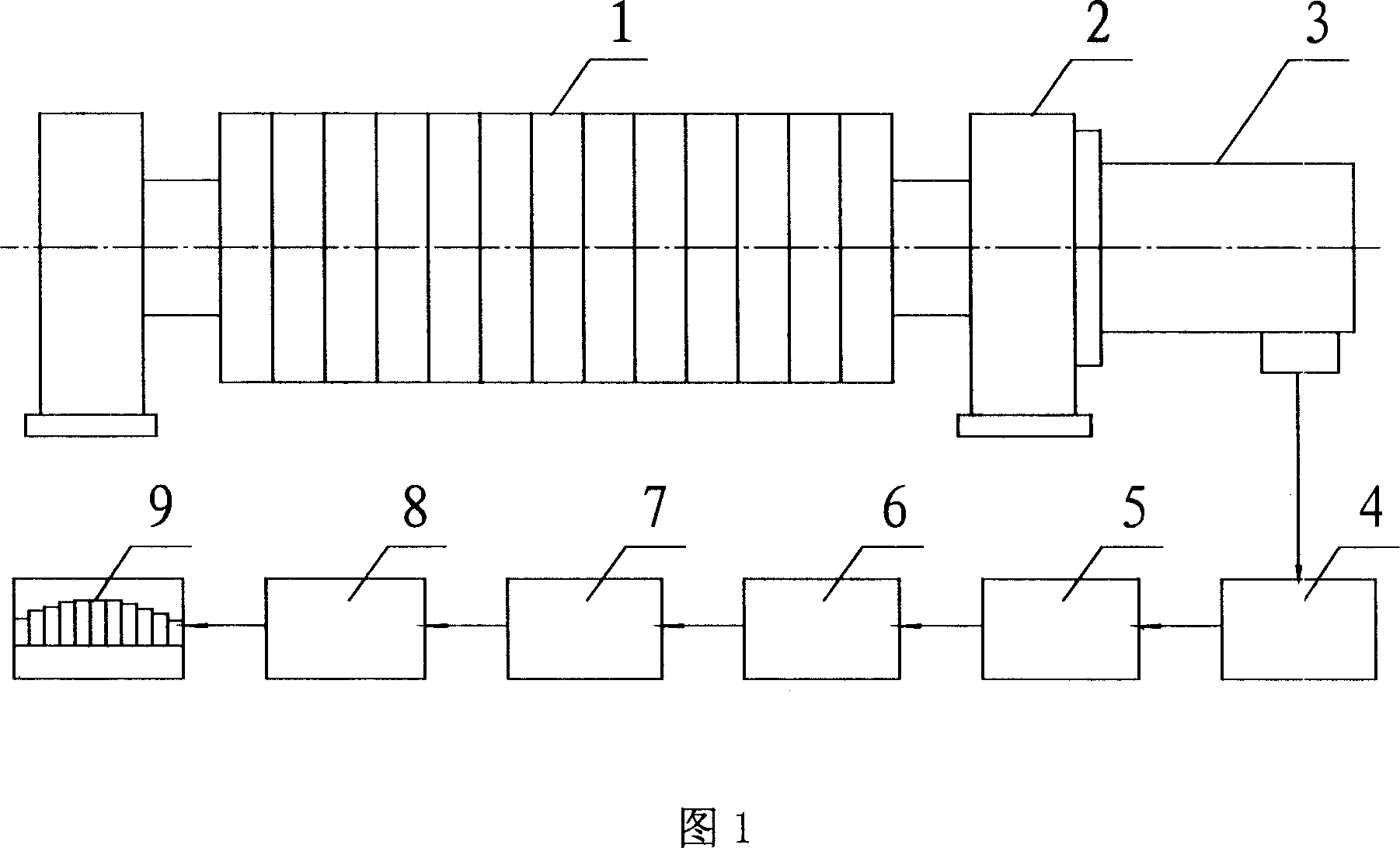

Split plate profile instrument with piezomagnetic internal pores

A shape meter, magnetic technology, applied in instruments, electromagnetic measuring devices, electrical/magnetic roughness/irregularity measurement, etc., can solve the problems of application limitation, harshness, and easy blocking of the air passage of the inspection roller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

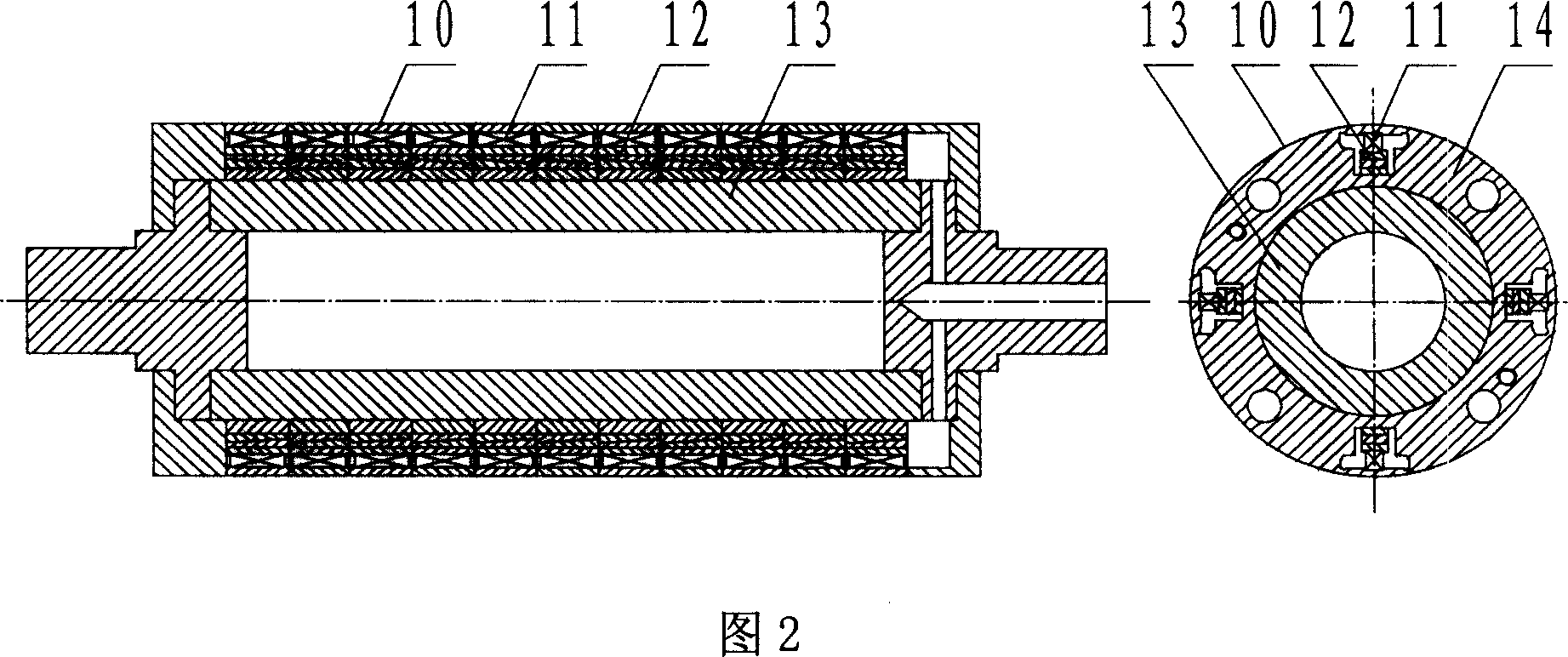

[0014] Fig. 2 is an embodiment of the slice inner hole piezomagnetic type shape meter disclosed by the present invention. The detection roller 1 installs 15 independent roller sheets 10 on a hollow mandrel 13 in the form of interference fit, and all The end covers at both ends of the roll sheet 10 and the roll body are fixedly connected together by four long pin bolts. Each roller sheet is composed of sheet body 14, piezomagnetic pressure sensor 11 and self-locking pad 12. Four piezomagnetic pressure sensors 11 with similar performance are installed in the cavity at the circumferential symmetrical position of sheet body 14. By self-locking The adjustment pad 12 fixes the sheet body 14 and the piezomagnetic sensor 11 as a whole, and at the same time, utilizes the extremely small inclination of the self-locking adjustment pad 12 to precisely adjust the preload of the piezomagnetic sensor 11 .

[0015] The working principle of the sliced inner hole piezomagnetic shapemeter is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com