Alcohol-base vaporizing reforming fuel combustor

A burner and fuel technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of inappropriate fuel combustion, tempering, and insufficient combustion, and achieve less emissions, high combustion efficiency, and increased load The effect of adjusting the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

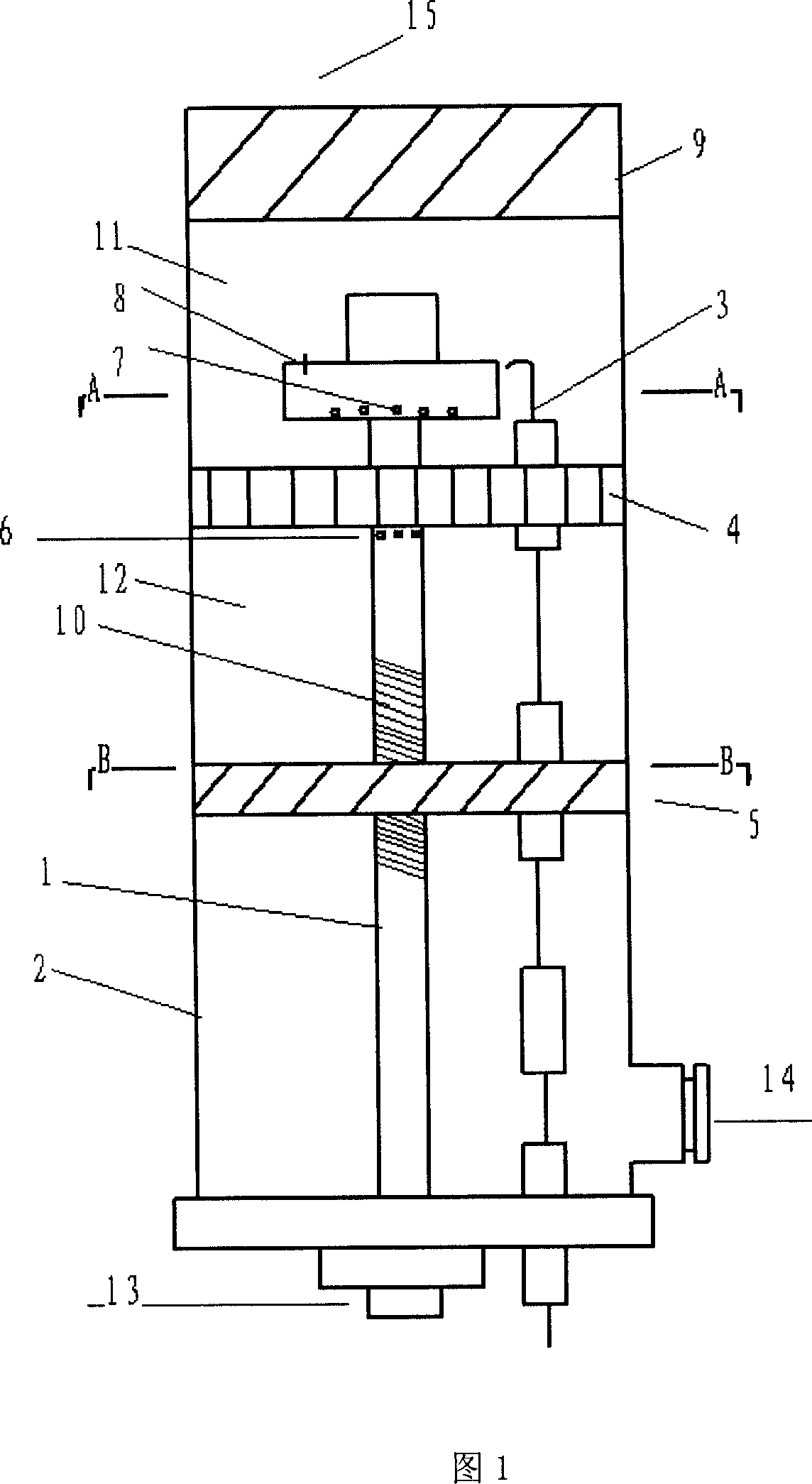

[0016] Further illustrate the present invention below in conjunction with accompanying drawing.

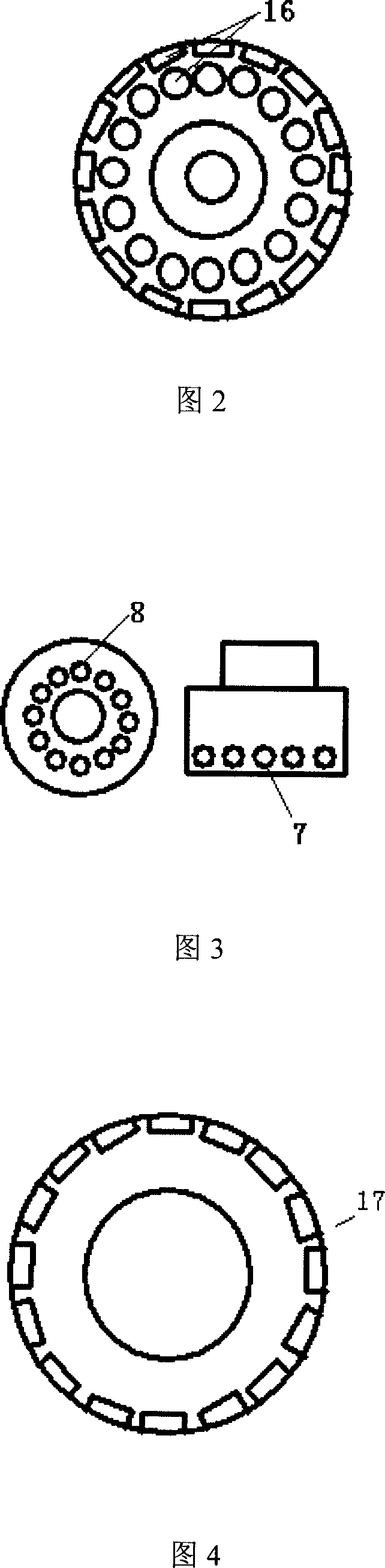

[0017] Fig. 1 is a schematic diagram of the structure of the present invention. Among them, 1. Intake pipe, 2. Burner shell, 3. Electric igniter, 4. Direct current piece, 5. Swirling flow piece, 6. Gas nozzle I, 7. Gas nozzle II, 8, Gas nozzle III, 9, Heat gathering diffuser, 10, thread, 11, mixing one chamber, 12, mixing two chambers, 13, gas inlet, 14 hot air inlet, 15, flame surface. An alcohol-based gasification and reforming fuel burner, which consists of an intake pipe (1), a burner casing (2), an electric igniter (3), a direct current piece (4), a swirl piece (5), a gas nozzle I (6 ), gas nozzle II (7), gas nozzle III (8), and heat-gathering diffusion sheet (9);

[0018] Air intake pipe (1) is arranged in the burner casing (2), and the lower part of the air intake pipe (1) is an air inlet (13); there are threads and a group of horizontal gas nozzles I (6) on the air intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com