Stator permanent-magnet double salient pole fault-tolerant motor

A permanent magnet, doubly salient pole technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of poor phase independence, increased motor weight, large eddy current loss, etc. problems, to achieve high reliability, reduce torque ripple, and easy cooling design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

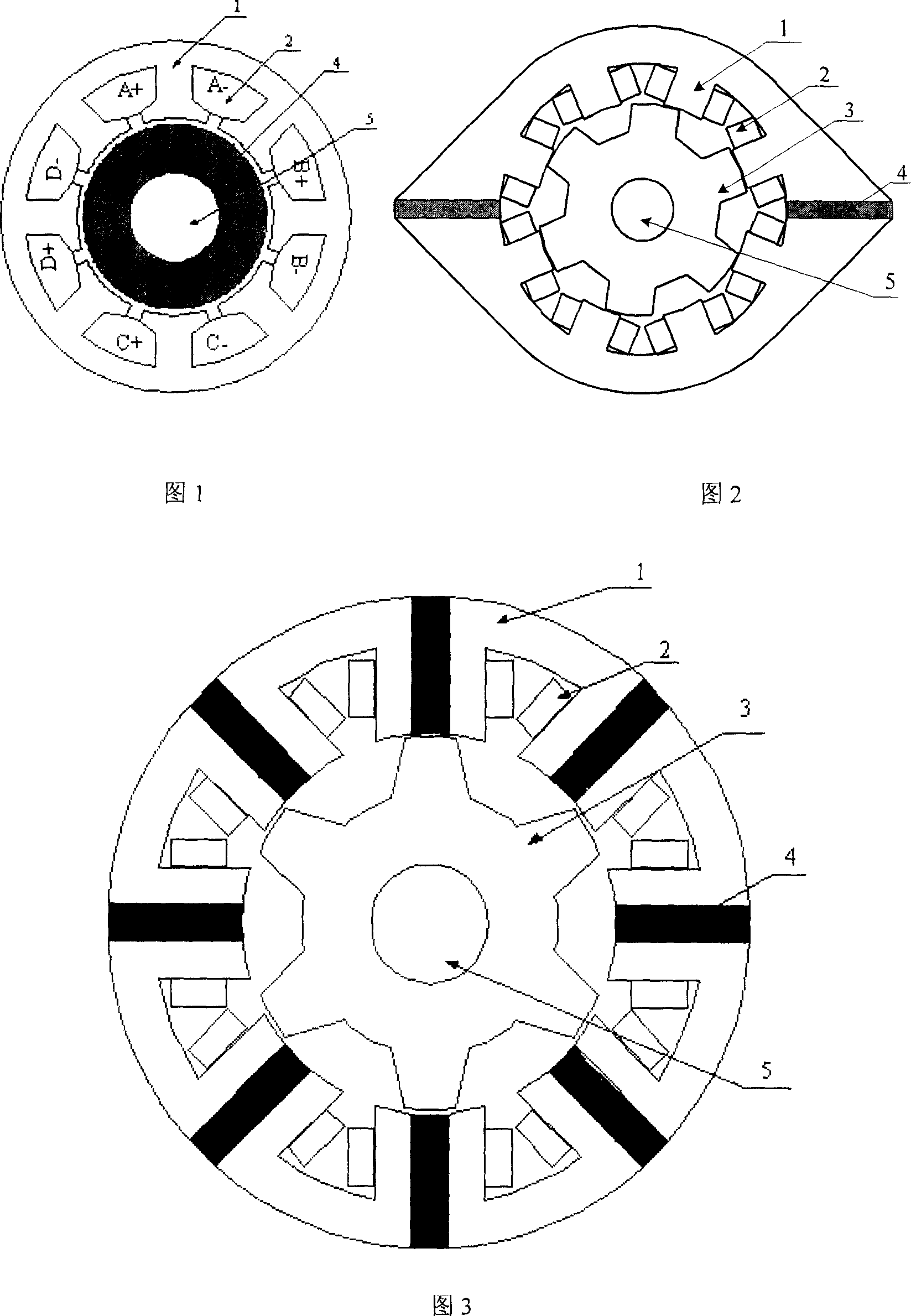

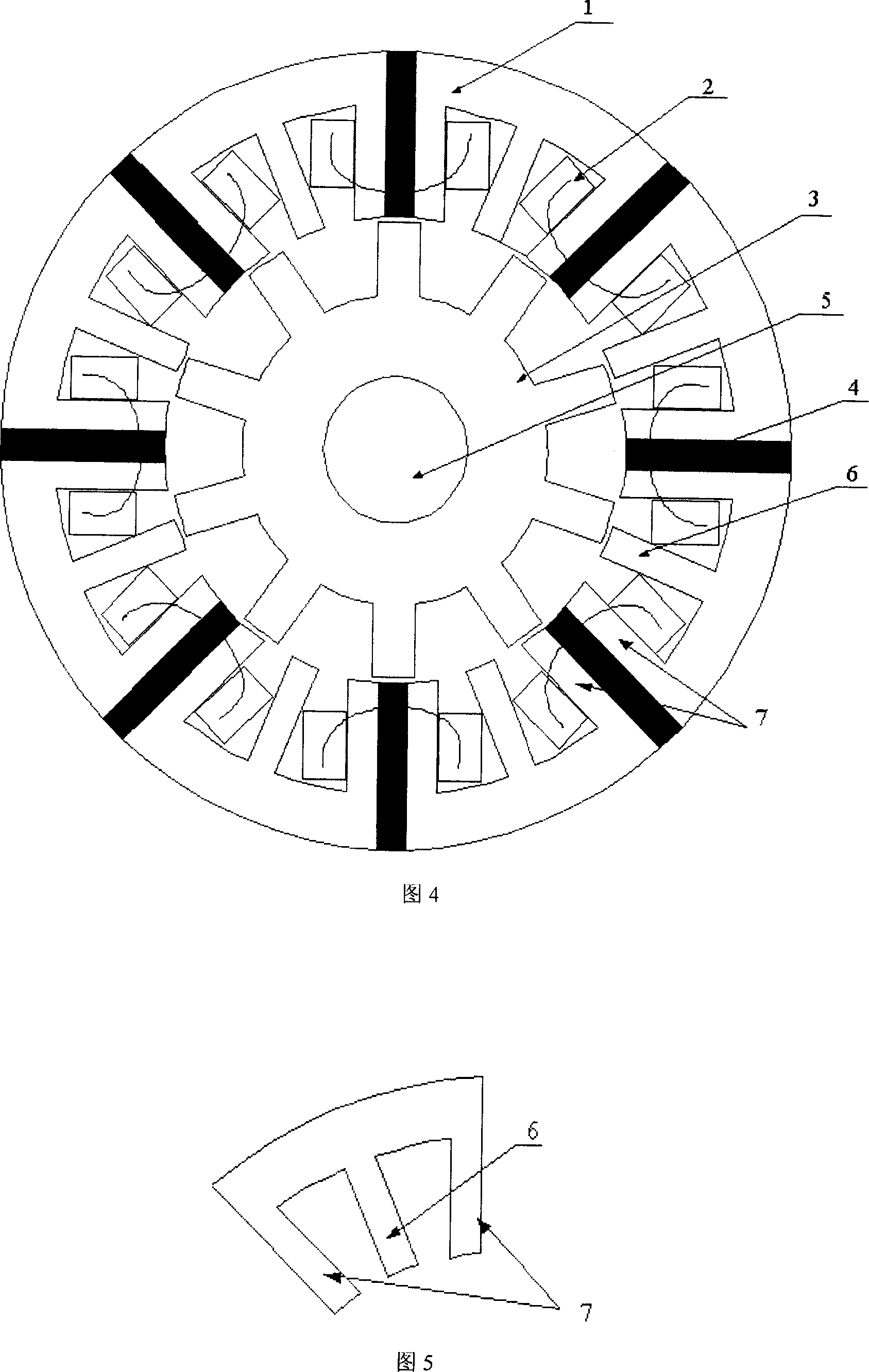

[0027] Taking a four-phase stator permanent magnet double-salient pole fault-tolerant motor as an example, its cross-sectional view is shown in Figure 4. The stator is composed of 8 mountain-shaped stator cores 1 and 8 permanent magnets 4. The mountain-shaped stator core 1 and rotor core 3 are punched into punching sheets with silicon steel sheets with a thickness of 0.37mm according to the shape shown in Figure 5 and the rotor shape shown in Figure 4, and enough punching sheets are laminated to form stator core 1 and Rotor core 3. The stator winding 2 is a concentrated winding, which is wound on the armature teeth with the permanent magnet 4, and each slot has only one phase winding 2, and the radially opposite two-pole windings 2 are connected in series to form a phase, and the phase and phase windings are connected by a fault-tolerant Teeth 6 are isolated, and there is no winding on the fault-tolerant teeth 6, and no permanent magnets.

[0028] The following is a rated pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com