Vertical shaft type windmill and blade for windmill

A vertical shaft and vane technology, applied in the field of starting mechanism, can solve the problems of device complexity, battery life damage, noise increase, etc., and achieve the effect of simple structure, improved starting performance and improved starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

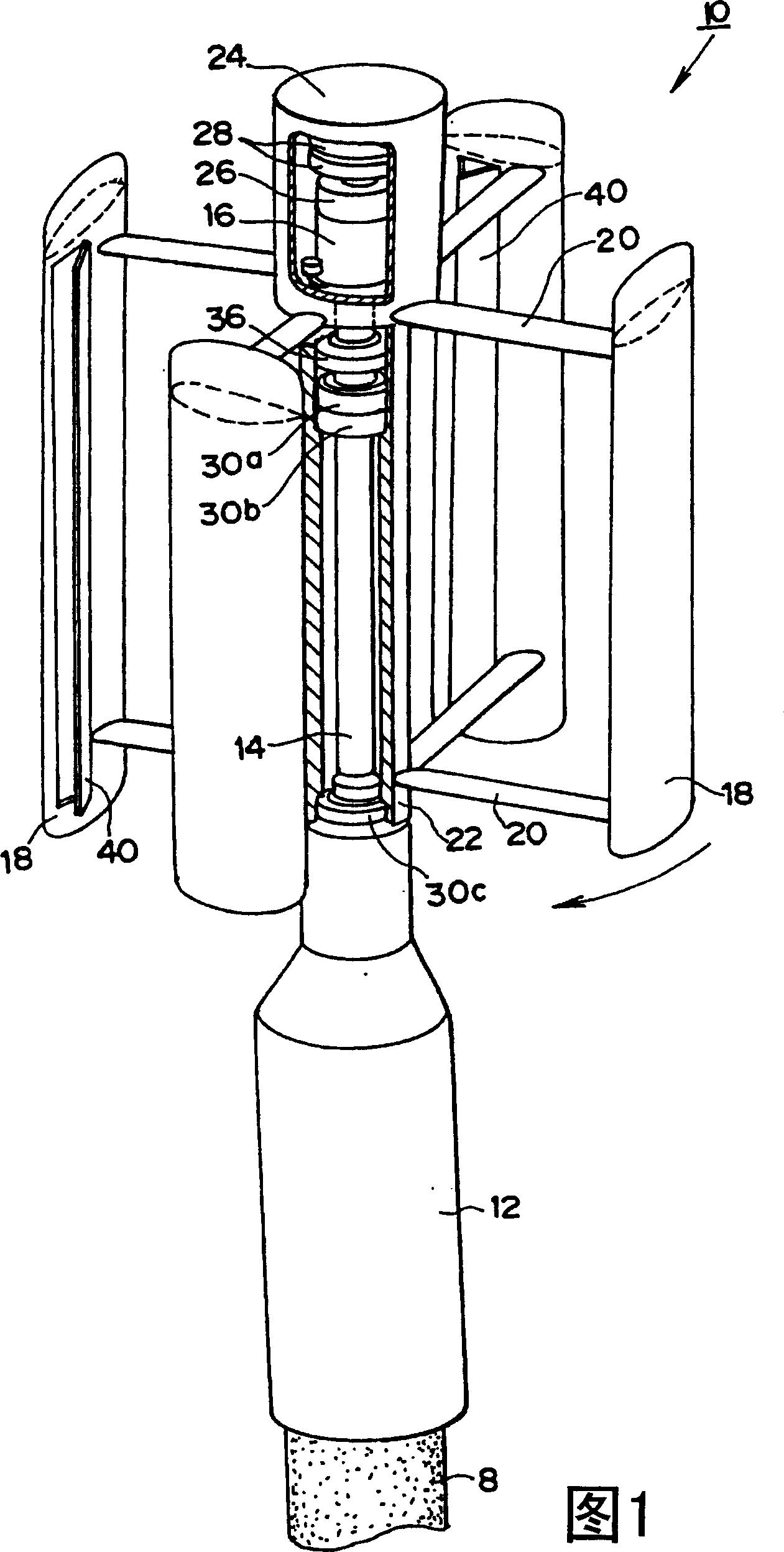

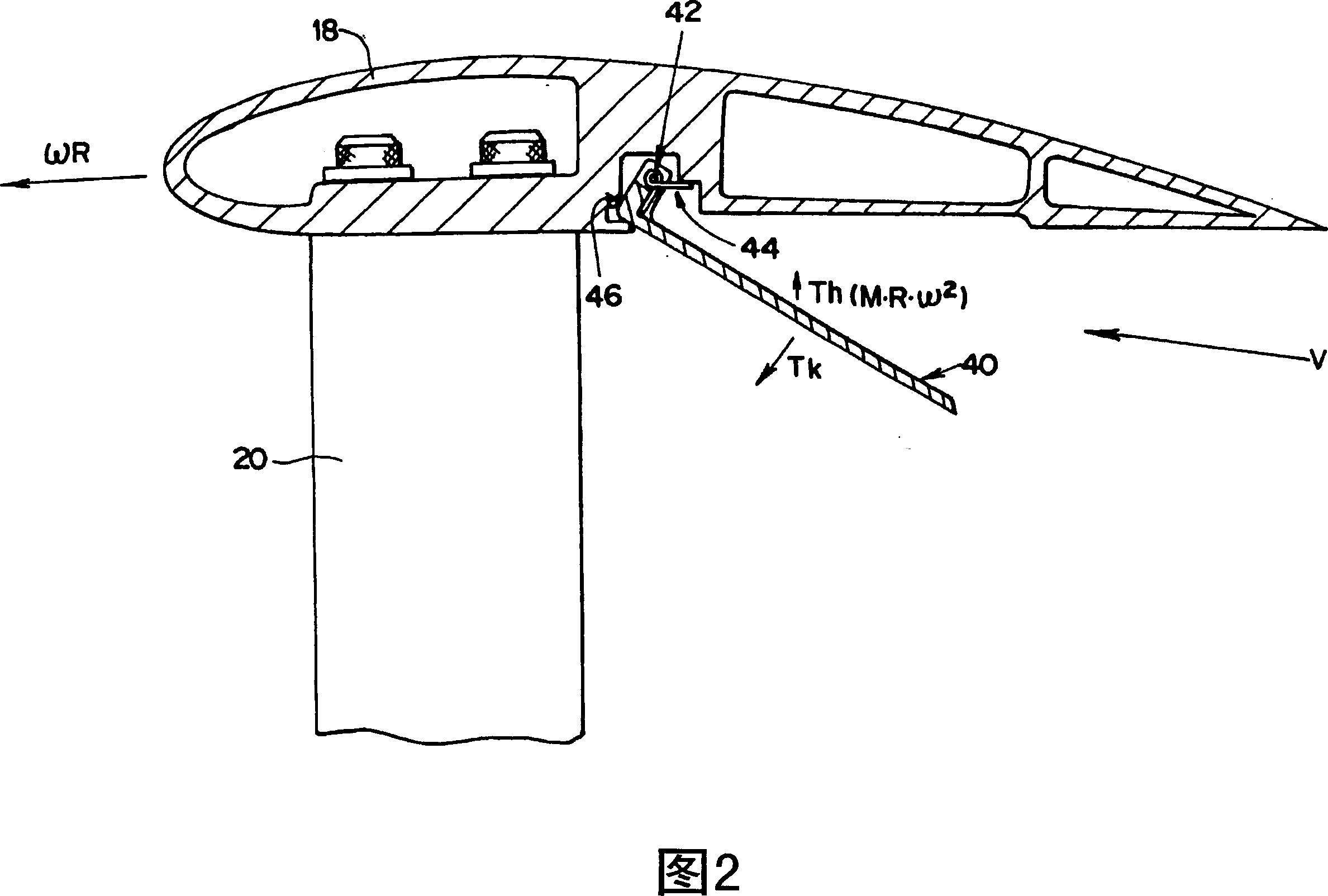

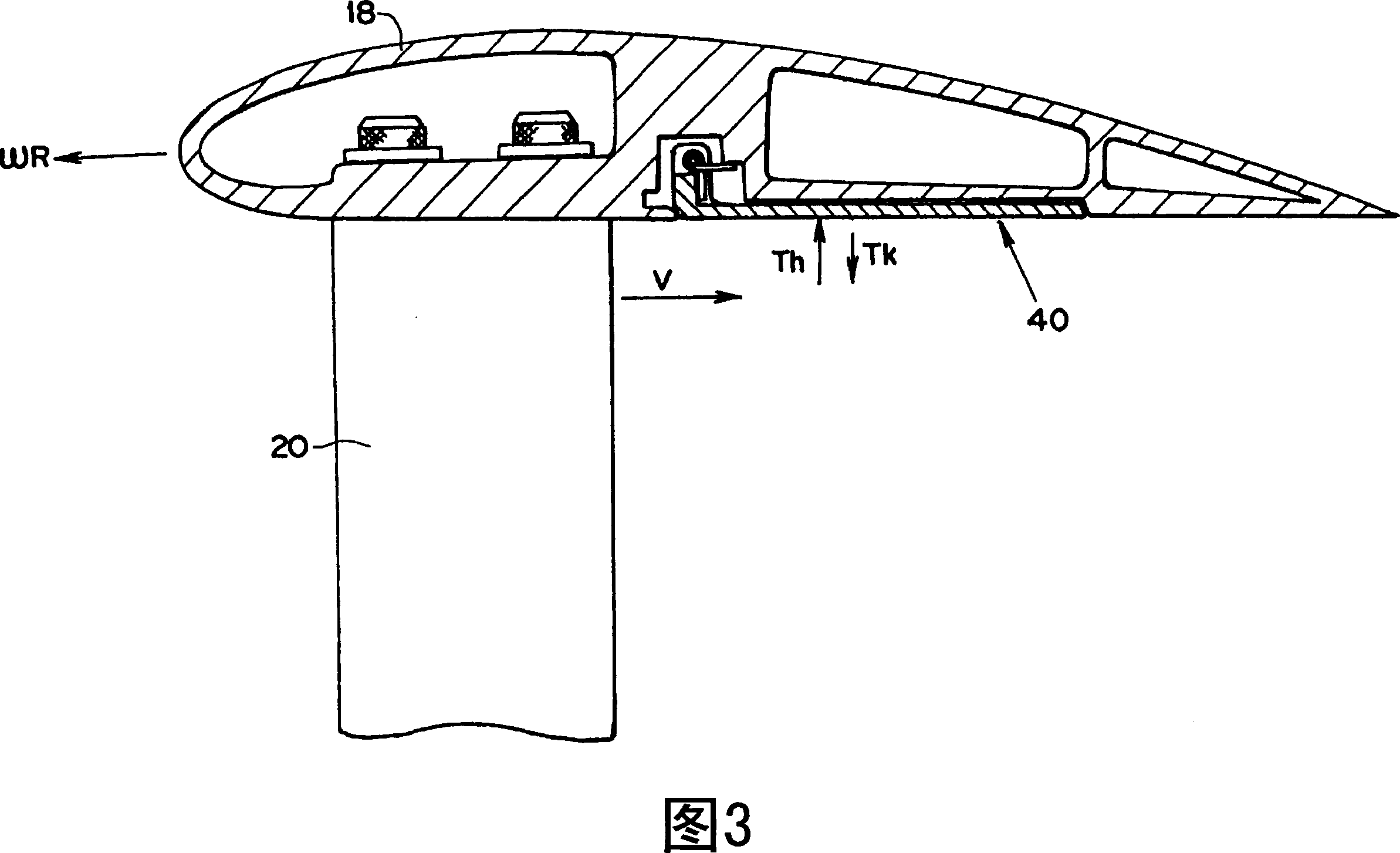

[0055] Hereinafter, the structure of the vertical-axis windmill and the blade for windmills concerning this invention is demonstrated. Fig. 1 is an external perspective view of a vertical axis windmill and blades for the windmill.

[0056] As shown in FIG. 1 , the vertical axis windmill 10 is provided with: a mounting part 12 installed on a utility pole or other poles 8; a fixed shaft 14 fixed together with the mounting part 12; a generator 16 arranged on the fixed shaft 14 Upper end; blade 18, which converts wind speed into lift force to generate torque; support arm 20, which has a streamlined section, supports blade 18 from up and down; outer ring sleeve 22, installs support arm 20; torque transmission cover 24, covers the outer ring The torque of the drum 22 is transmitted to the generator 16 .

[0057] In the example shown in FIG. 1 , a speed increaser 26 is attached to the input shaft of the generator 16 , and the rotation of the outer sleeve 22 is accelerated by the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com