Piston and method of manufacture

一种活塞、感应加热的技术,应用在活塞、金属加工设备、制造工具等方向,能够解决无法感应线圈放置在、通道有限、活塞设计困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

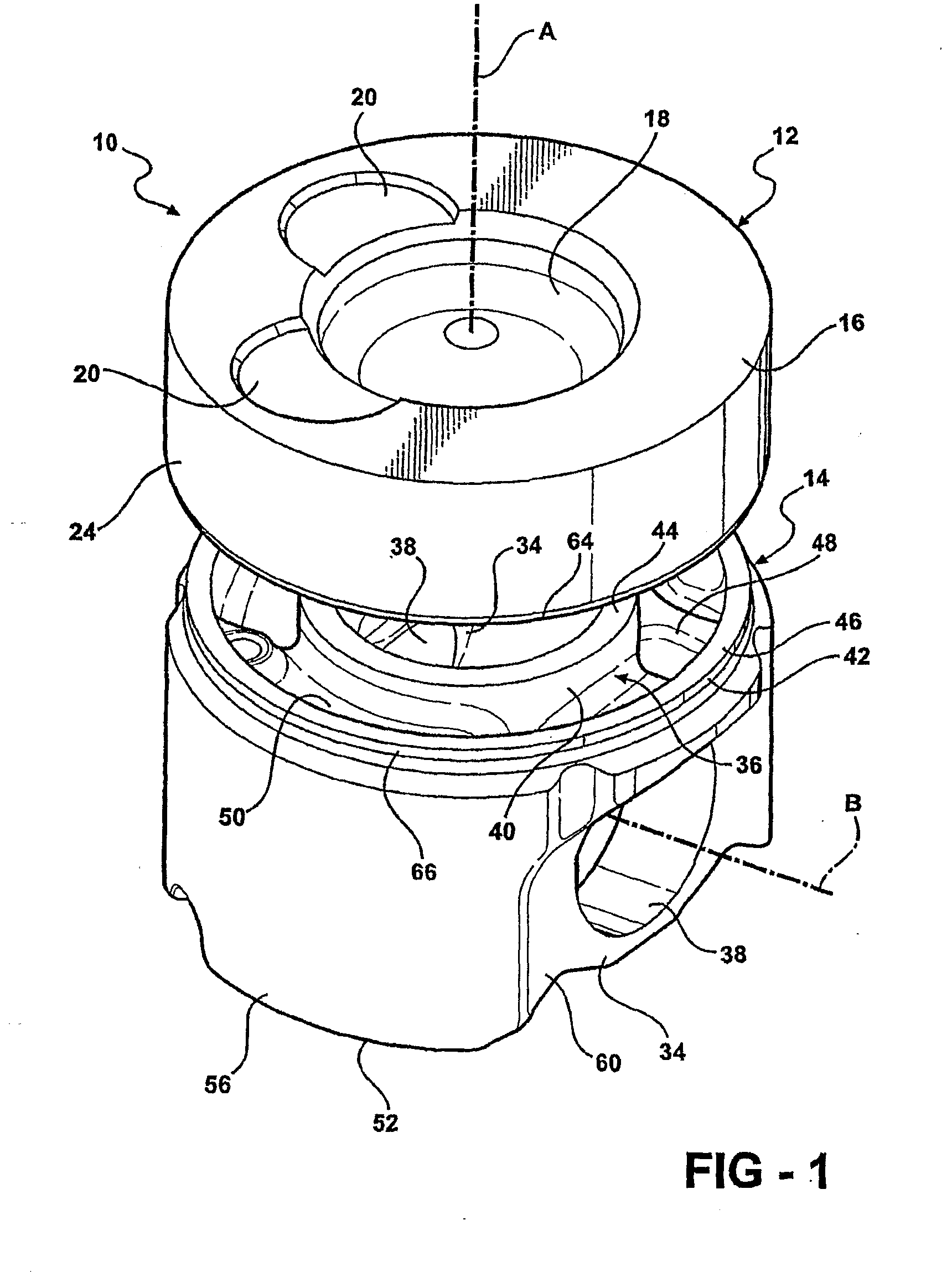

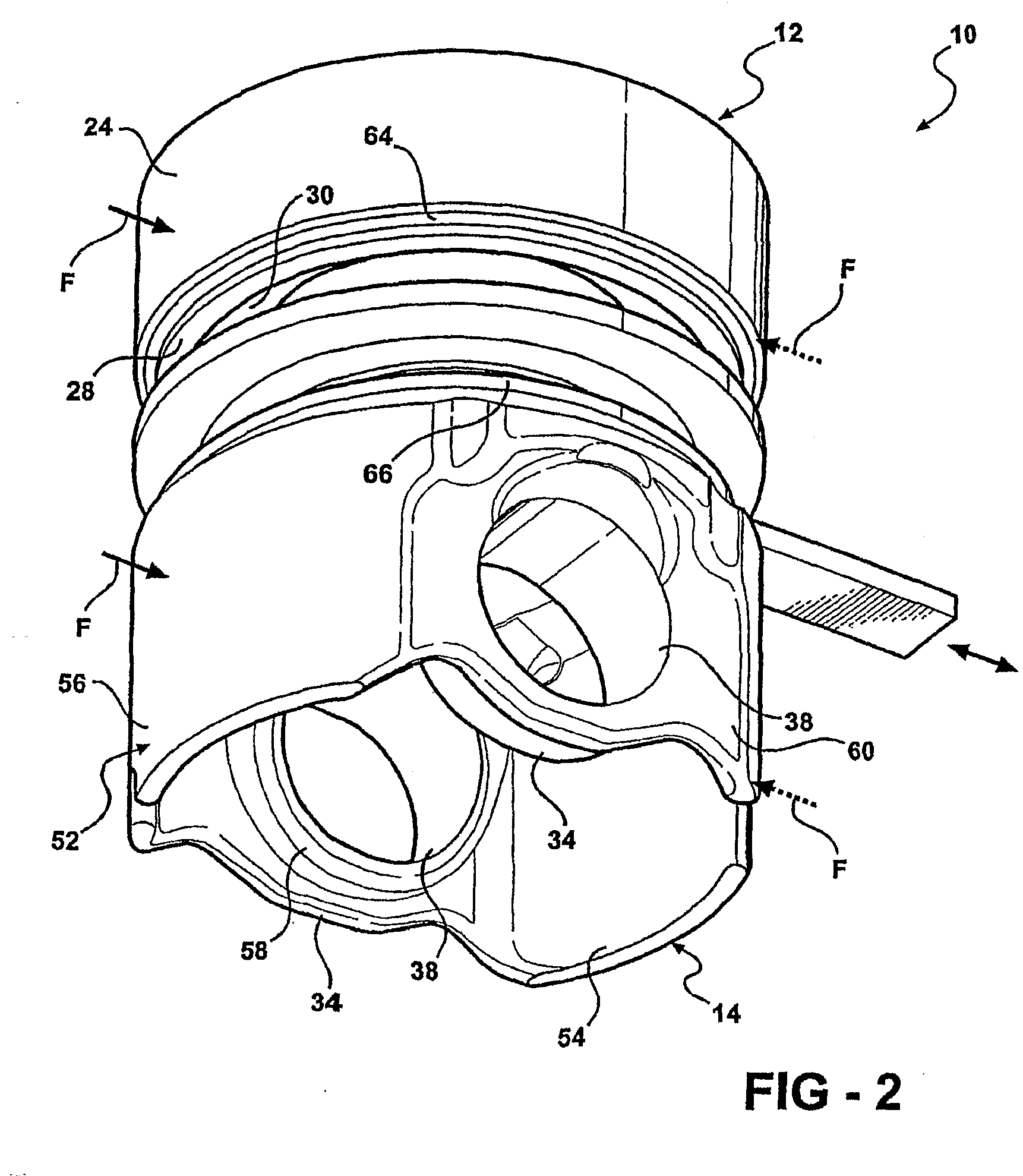

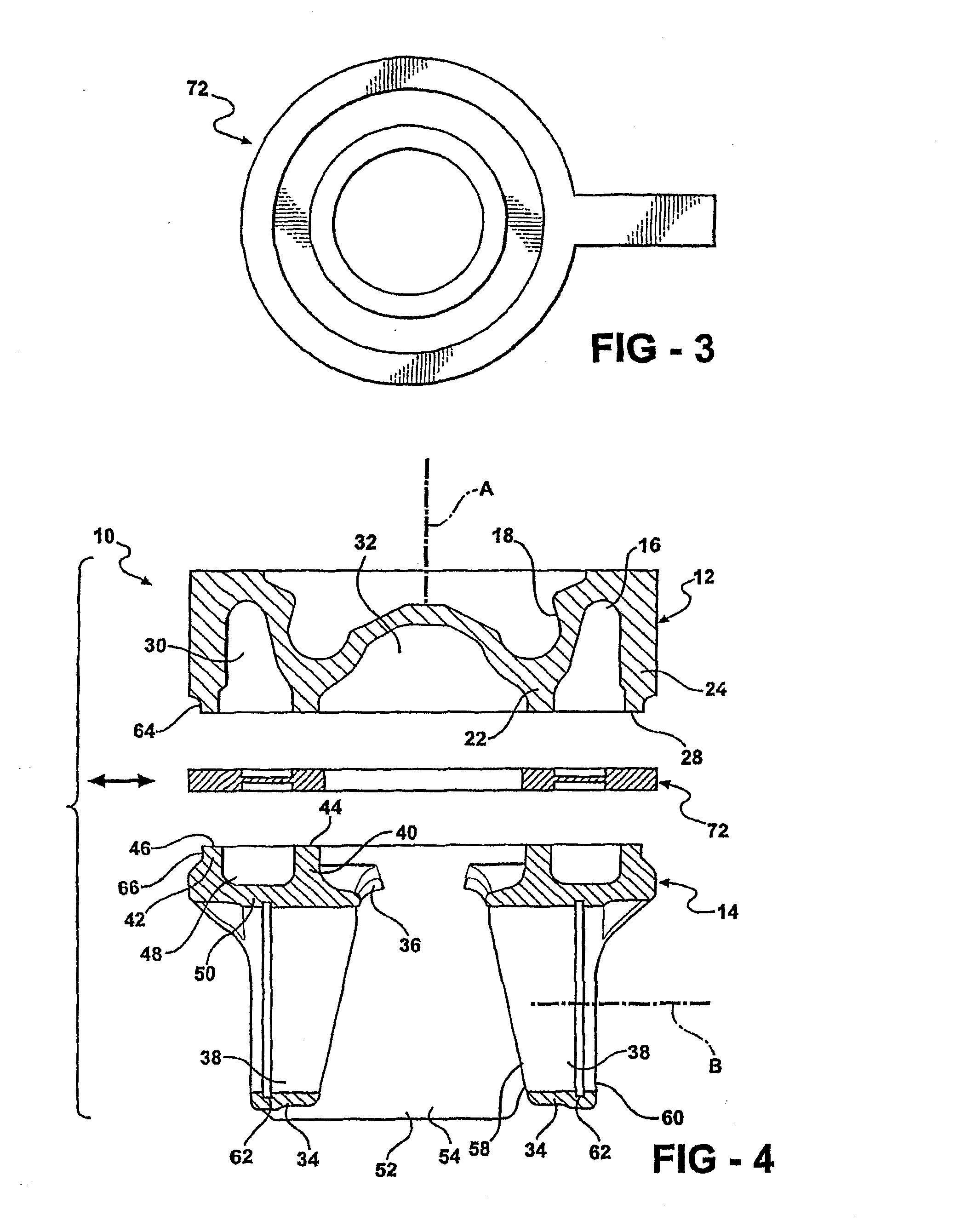

[0026] Reference numeral 10 in the figure generally shows a piston manufactured according to the presently preferred embodiment of the present invention, which is composed of at least two separate parts, with at least one pair or preferably at least two pairs of cooperating welds extending circumferentially. On the surface, they are initially separated from each other, then heated to a temperature suitable for welding, and after heating, they are joined to each other to form a permanent weld between the parts.

[0027] In the illustrated embodiment, the piston 10 includes a first component 12 and a second component 14 . Both parts 12 and 14 are made of metal—preferably alloy steel, although the material of the present invention is not limited thereto. The first and second parts may be cast, forged, produced by powder metallurgy, or manufactured by any other method of making metal parts. The first and second parts 12, 14 can be made of the same or different alloys, so the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com