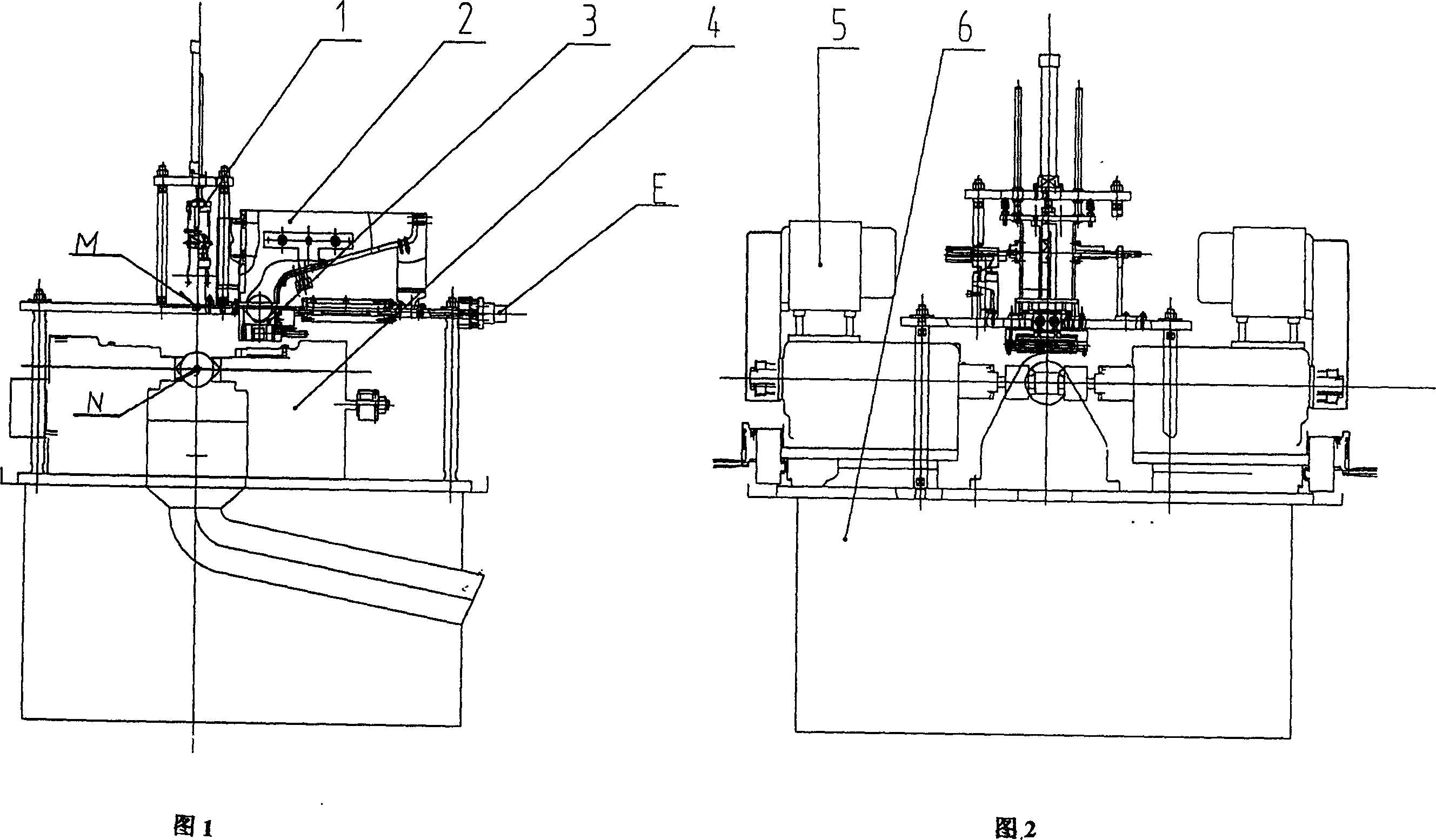

Automatic butt beveler of DC electric motor casings

A DC motor, fully automatic technology, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of difficulty in adapting to the development of DC motors, difficult to guarantee the machining accuracy of the shell, low processing efficiency, etc., and is conducive to uniformity. The effect of wear, dust and chip resistance, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

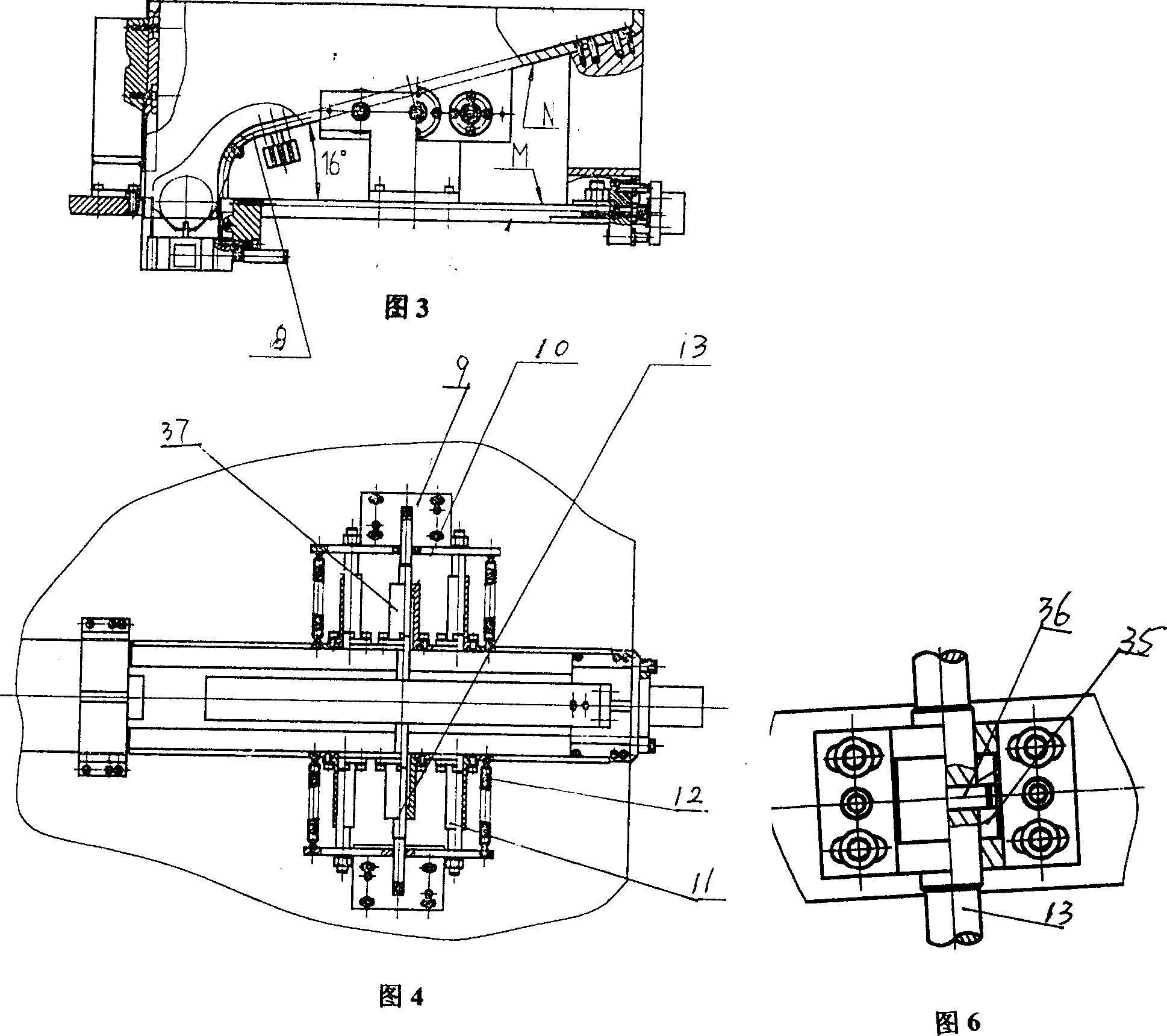

[0025] The feeding bin 2 includes: a material receiving bottom plate 8, a vertical side plate 7, and an adjusting plate width structure 9 connected to the vertical side plate 7.

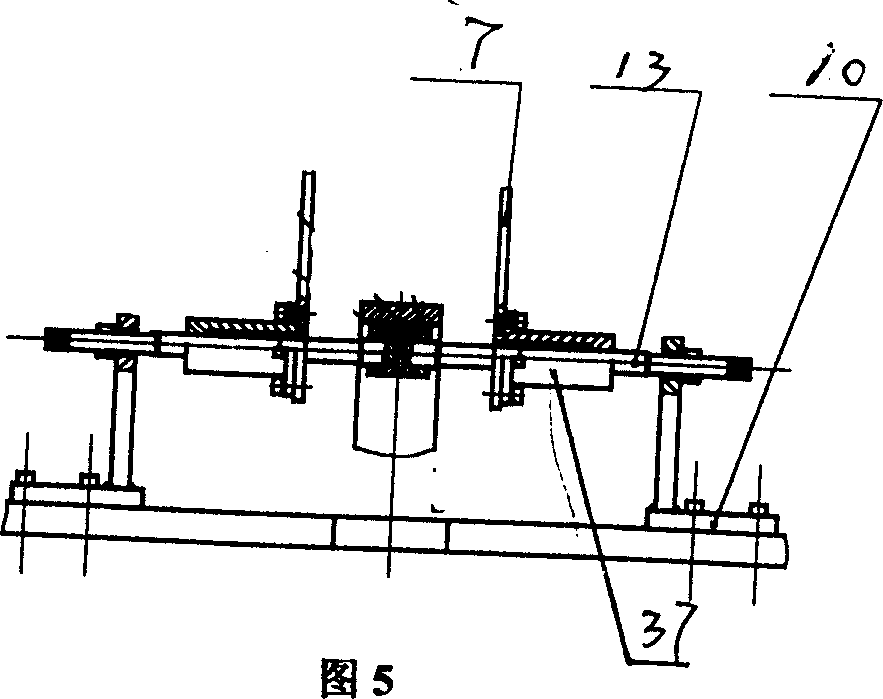

[0026] Horizontal feeding hopper 3 comprises: slide block 19 is contained in the body 15, and slide block 19 one end is equipped with roller 34, and this roller 34 contacts with slide plate 16 central grooves, slide plate 16 links to each other with the cylinder rod of drive cylinder 17, slide block 19 and The center block 18 is connected, under the action of the slide plate 16, the center is reciprocated (opened and closed), the socket 35 is connected with the body 15, and the quick-change plug has different diameters (φ45-62) to adapt to different diameters. artifact.

[0027] A centering clamping device 4 includes: the cylinder 21 is connected to the connection plate 22, the clamping main shaft 24, one end of the transmission rack 32 are connected to the connection plate 23, the other end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com