Pin-hole main and auxiliary fin buckling board

A technology of auxiliary ribs and locking plates, which is applied to floors, coverings/linings, buildings, etc., can solve the problems of easily damaged house structures, high stress on wooden floors, and deformation of wooden floors, so as to improve installation quality, facilitate maintenance, Fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

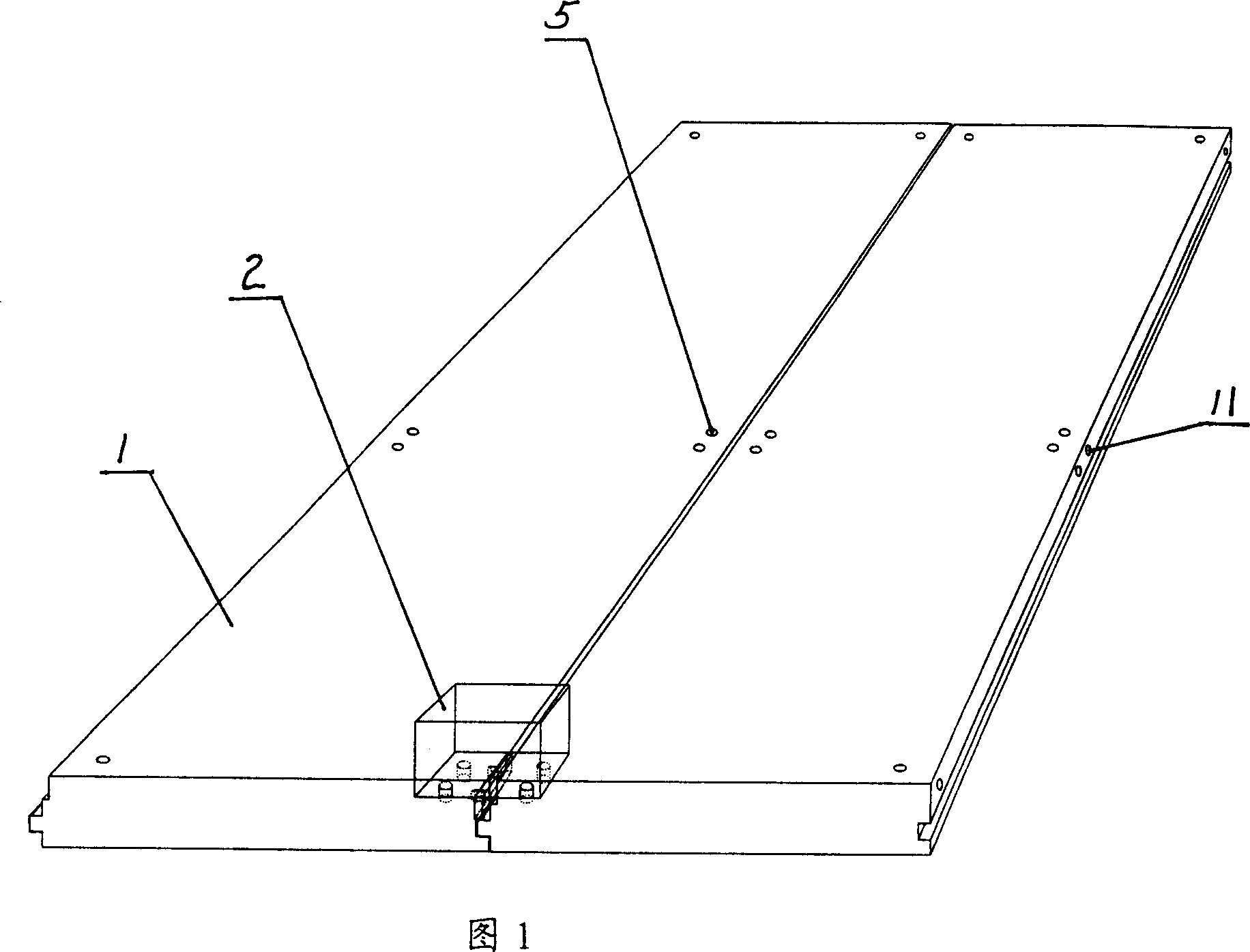

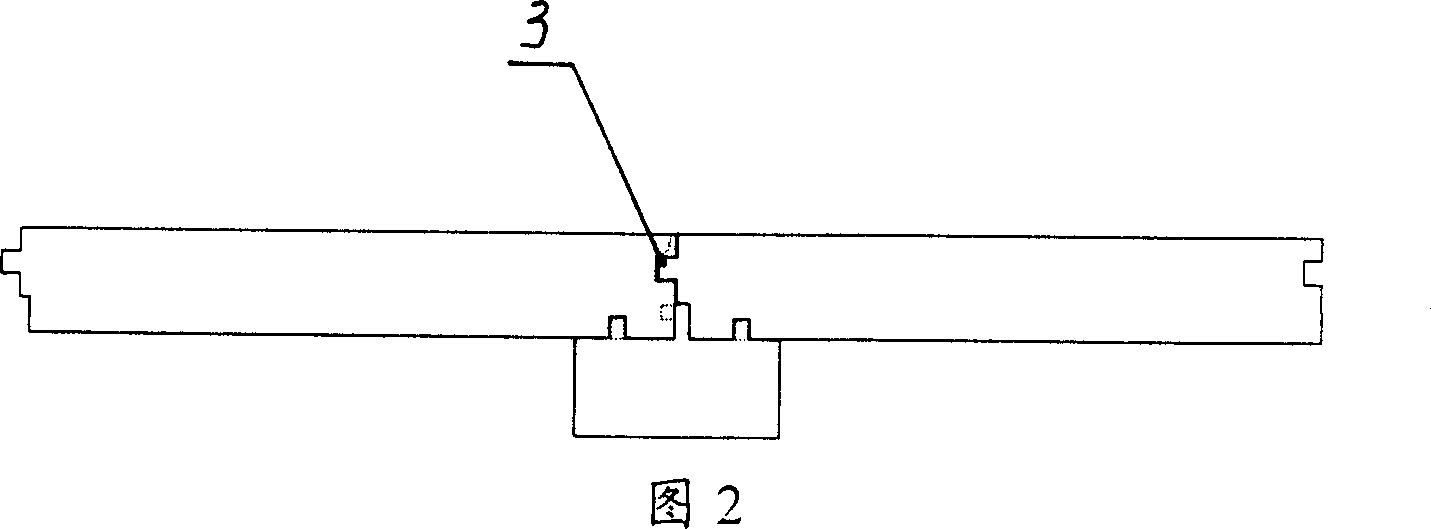

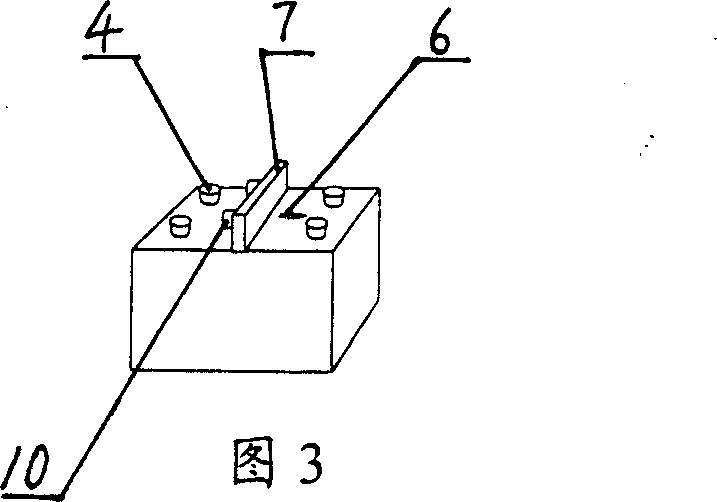

[0022] Embodiment 1: Refer to Figs. 1 to 3. This embodiment is composed of a plate 1 and a keel 2. The two adjacent plates 1 are matched by the main rib 7 and the female and male grooves 3. The surface of the keel 2 is provided with two rows of auxiliary ribs arranged in parallel, and each row of auxiliary ribs consists of two pins. The shaft 4 is composed of two pin holes 5 matched with the above-mentioned pin shaft 4 on each side plate 1 on the back of the two side plates at the splicing seam of adjacent plates. The main rib 7 is arranged between the two rows of auxiliary ribs, and is parallel to each row of auxiliary ribs. A protruding main rib connecting body is provided on the left side wall of the main rib 7 and the main rib connecting body is composed of two main rib pins 10. A main rib pin hole 11 matched with the above-mentioned main rib pin shaft 10 is provided on the butt joint end surface of the joint of two adjacent plates 1.

Embodiment 2

[0023] Embodiment 2: Refer to Figures 4 to 6. This embodiment is composed of a plate 1 and a keel 2. The adjacent two plates are joined together by the main rib 7 and the male and female grooves 3. On the surface of the keel 2, there are two rows of auxiliary ribs arranged in parallel, and the main ribs 7 are arranged in two rows. Between the auxiliary ribs, parallel to each row of auxiliary ribs. A row of auxiliary ribs located on the left side of the main rib 7 is composed of two pin shafts 4, and a row of auxiliary ribs located on the right side of the main rib 7 is composed of strip-shaped convex ribs 9. A pin hole 5 matched with the above-mentioned pin shaft 4 and a groove 8 matched with the above-mentioned strip-shaped rib 9 are respectively provided on each side plate 1 on the back of the two side plates at the splicing seam of adjacent plates. A protruding main rib connecting body is provided on each side of the left and right side walls of the main rib 7 and the main rib ...

Embodiment 3

[0024] Embodiment 3: Refer to Figs. 7-9. This embodiment is composed of a plate 1 and a keel 2, and the main ribs 7 and the female and male grooves 3 are matched and spliced together between the two adjacent plates. Two rows of auxiliary ribs arranged in parallel are arranged on the surface of the keel 2, and the main ribs 7 are arranged between the two rows of auxiliary ribs and are parallel to each row of auxiliary ribs. A row of auxiliary ribs located on the left side of the main rib 7 is composed of two pin shafts 4, and a row of auxiliary ribs located on the right side of the main rib 7 is composed of strip-shaped convex ribs 9. A pin groove 13 matching the pin shaft 4 of the keel 2 and a groove 8 matching the strip-shaped rib 9 of the keel 2 are respectively provided on each side panel 1 on the back of the two side panels at the splicing seam of adjacent panels. A protruding main rib connecting body is provided on each side of the left and right side walls of the main rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com