Method and device for cleaning semiconductor crystal wafer

A technology for cleaning equipment and wafers, applied in liquid cleaning methods, cleaning methods and utensils, semiconductor/solid-state device manufacturing, etc., can solve the problem of limited wafer pre-rinsing capabilities, unsuitable operating habits, and large consumption of pure water and other problems, to achieve the effect of saving pure water consumption, saving pure water consumption, and avoiding water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

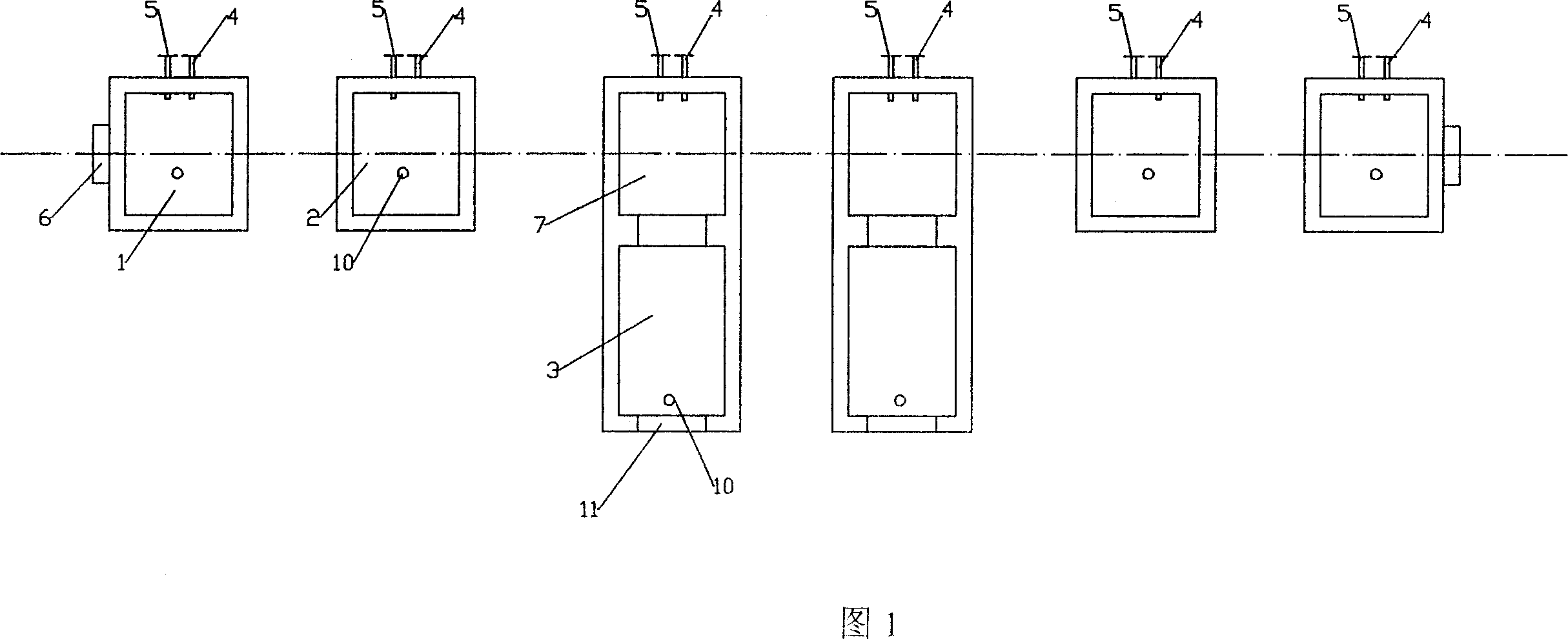

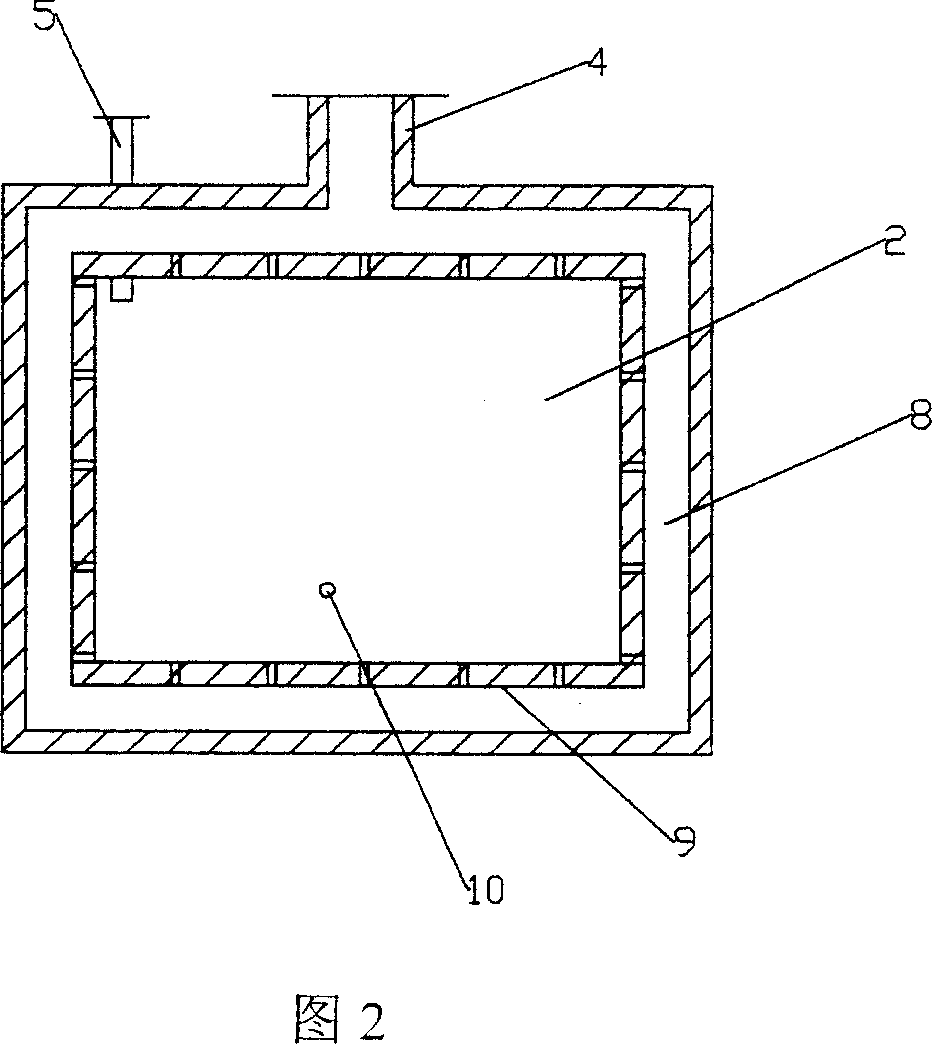

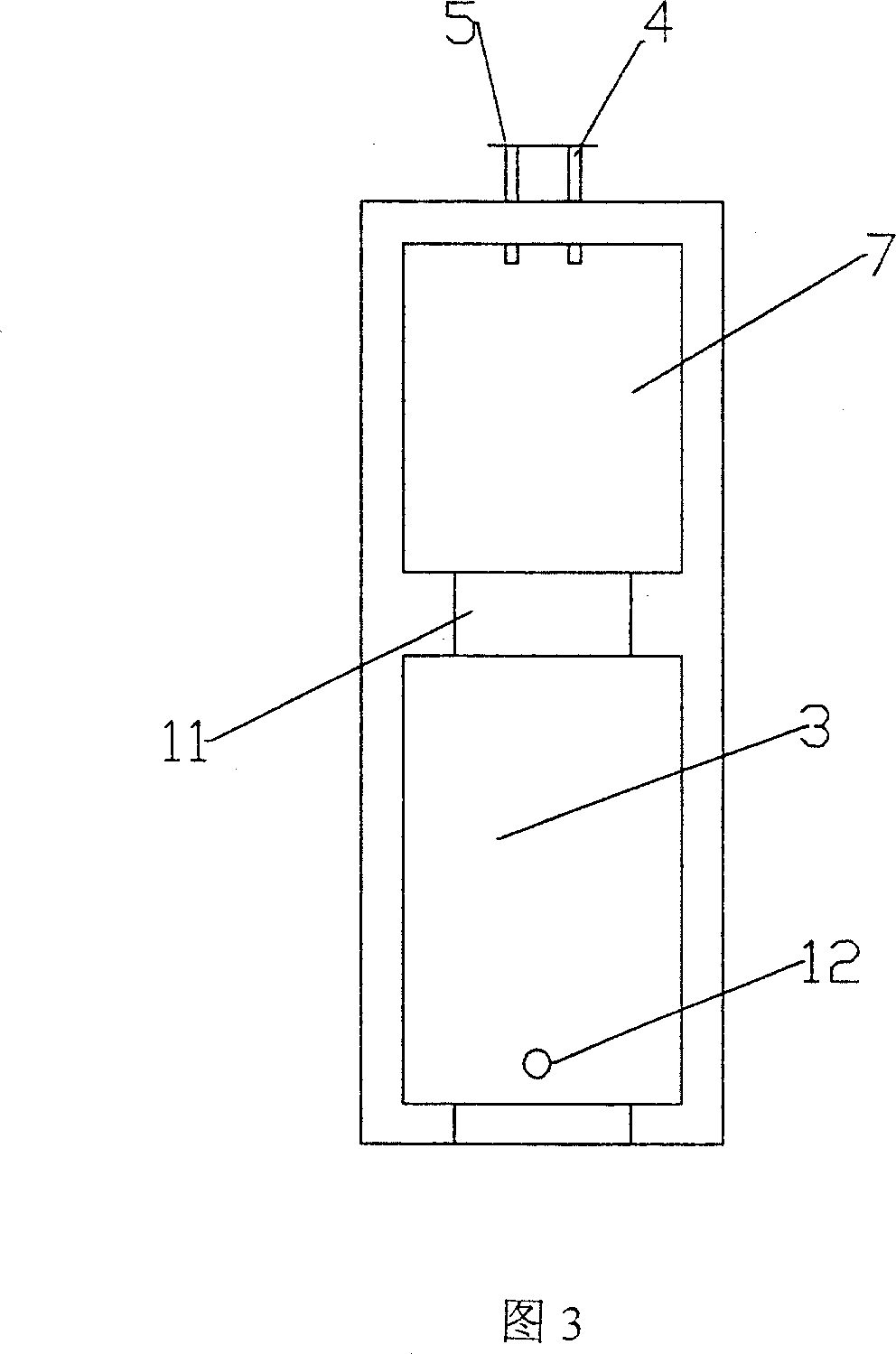

[0024] The present invention mainly adopts corrosion tank 1, spray type pre-flushing tank 2, step type high and low flushing tank 7, 3 two to form a group (system) to be the left step type flushing tank, independent of each other. When in use, two sets of left and right stepped flushing tanks can be used at the same time. There is a space between the left stepped flushing tank and the right stepped flushing tank (corrosion tank, spray pre-flushing tank, stepped high and low flushing tank), which can prevent the overflowing water from the tank from polluting each other. Ladder-type high and low flushing tanks 7 and 3 are arranged in front and back in steps, corrosion tank 1, spray pre-flushing tank 2, and stepped high and low flushing tank 3 are respectively connected to water inlet pipe 4 and air intake pipe 5 at the top and back, and elevator 6 is equipped on corrosion tank 1 , the elevator 6 continuously lifts the semiconductor wafer during operation. The intake pipe 5 is a...

Embodiment 2

[0034] In the embodiment of the present invention, two groups of the same left and right stepped flushing tanks in the first embodiment are used simultaneously. The process parameters are as follows: the liquid temperature of the etching tank is 30°C; 10 seconds before the completion of the corrosion operation, turn on the pure water, stepped flushing tank, and nitrogen switch of the spray pre-rinsing tank; put the semiconductor wafer into the spray pre-rinsing tank. Lift and pull up and down in the flushing tank 5 times for 10 seconds; then put the semiconductor wafer into the stepped low-flush water tank and flush for 4 minutes; transfer the semiconductor wafer to the stepped high-flush water tank and continue flushing for 4 minutes minutes, finally take it out, and dry it for 5 minutes at a speed of 880 rpm in a centrifugal dryer.

Embodiment 3

[0035] Embodiment 3: In the embodiment of the present invention, two groups of the same left and right stepped flushing tanks as in Embodiments 1 and 2 are used at the same time. The process parameters are as follows: the temperature of the liquid in the corrosion tank is 32°C; 12 seconds before the completion of the corrosion operation, turn on the pure water in the spray pre-rinse tank, the step-type flushing tank, and the nitrogen switch; put the semiconductor wafer into the spray pre-rinse tank. Pull up and down 6 times in the flushing tank for 12 seconds; then put the semiconductor wafer into the stepped low-flush water tank for 5 minutes; transfer the semiconductor wafer to the stepped high-flush water tank and continue flushing for 5 minutes minutes, finally take it out, and dry it for 6 minutes at a speed of 920 rpm in a centrifugal dryer.

[0036] In the second and third embodiments of the present invention, the semiconductor wafers cleaned by the above process parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com