Capacitive detecting structure and method for micro cantilever beam fatigue property

A fatigue characteristic and capacitance detection technology, applied in the field of micro-electronic mechanical system manufacturing for performance and reliability testing, can solve problems such as failure to reflect the decay process of micro-structure performance parameters, and achieve the effect of good reliability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

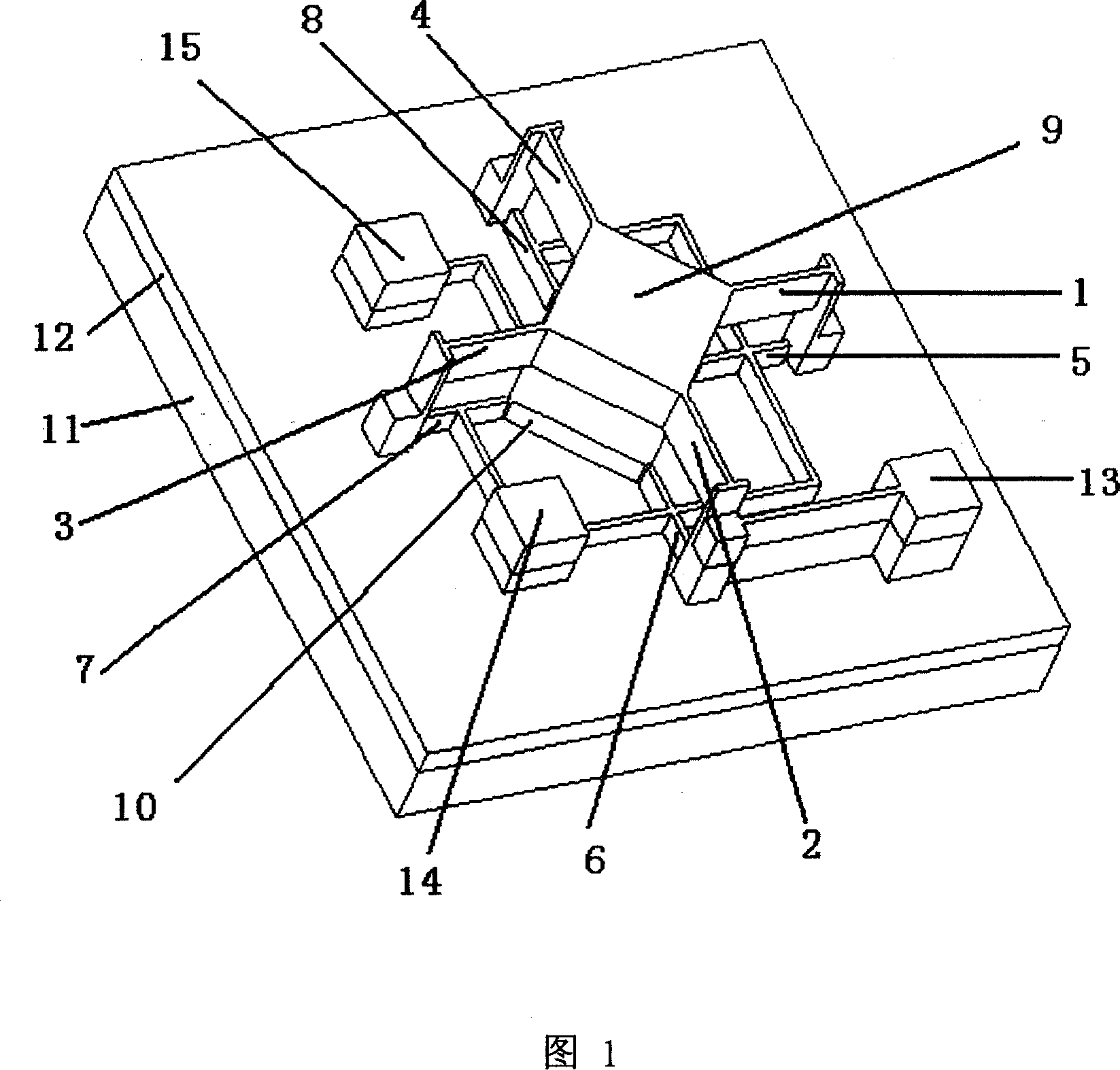

[0012] The present invention adopts the scheme shown in accompanying drawing to realize. The test structure is mainly composed of the following parts: the structure is to arrange a layer of nitride layer 12 on the silicon substrate 11, and a group of test structures are suspended above the nitride layer 12. The center of the test structure is a film 9, The first cantilever beam 1, the second cantilever beam 2, the third cantilever beam 3, and the fourth cantilever beam 4 are respectively connected to the four corners of the membrane 9, and the outer ends of the four beams are respectively fixed on the nitriding Above the layer 12, a set of lower electrodes corresponding to the test structure is provided on the upper surface of the nitride layer 12, namely the first lower electrode 5, the second lower electrode 6, the third lower electrode 7, the fourth lower electrode 8, The fifth lower electrode The lower electrode 10, the first welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com