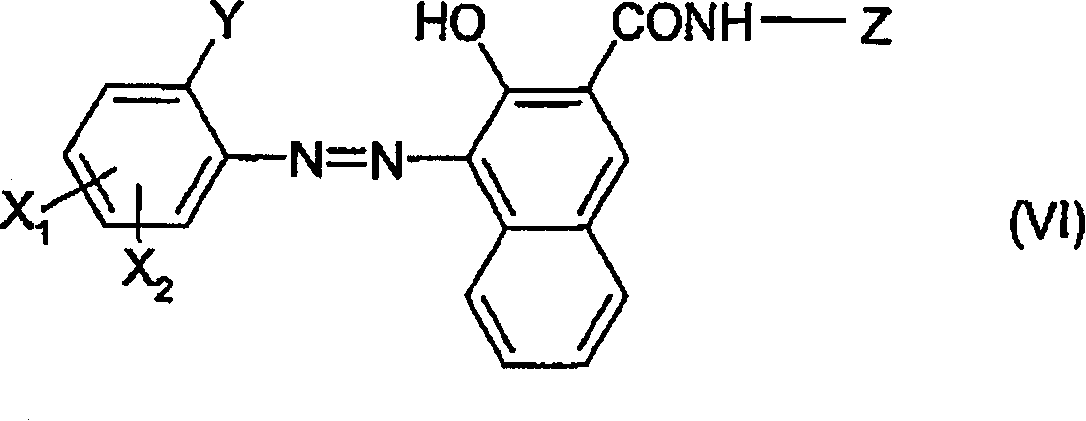

High-purity naphthol as pigments

A pigment, naphthol technology, applied in the field of azo pigments, can solve expensive, laborious, difficult and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

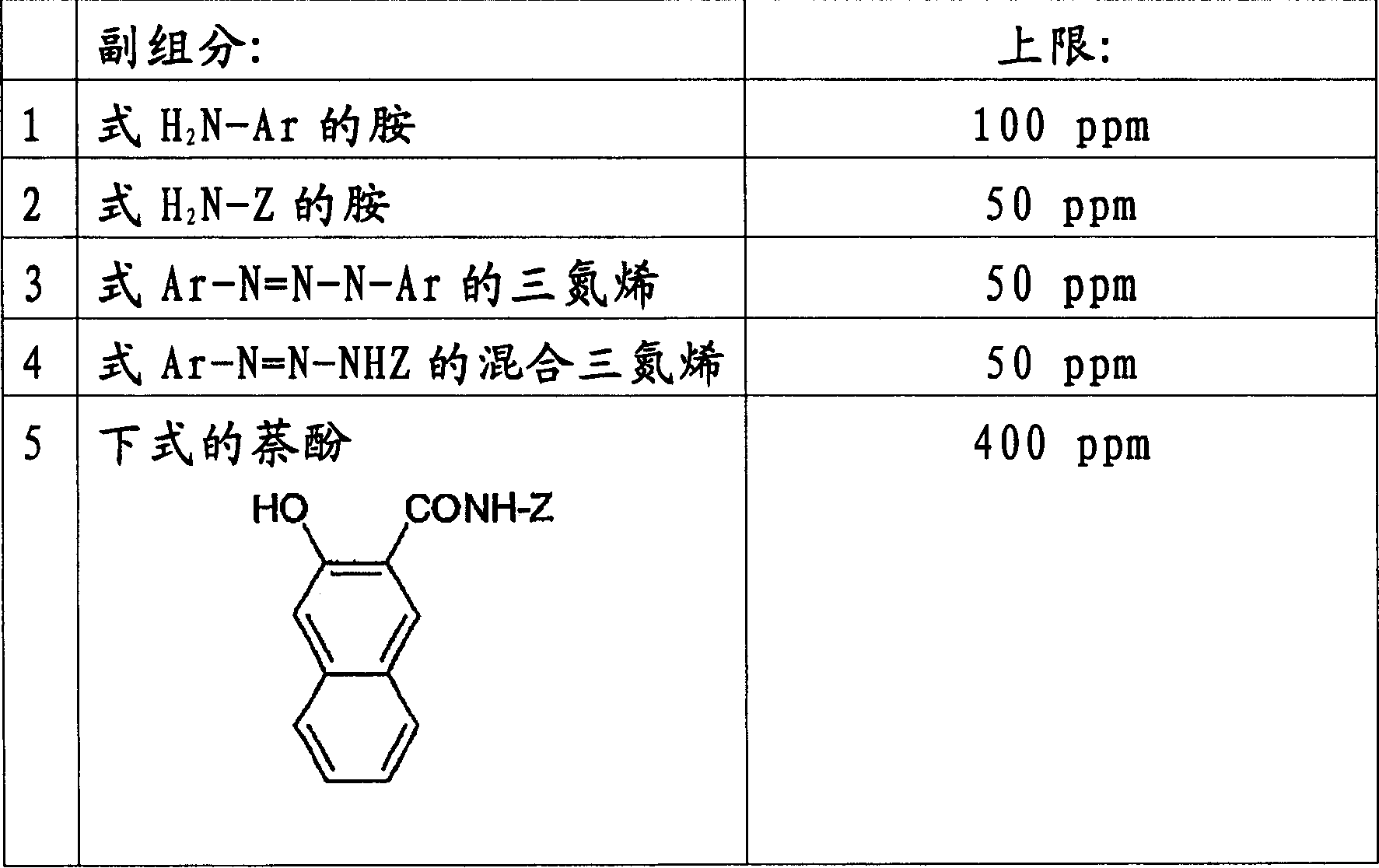

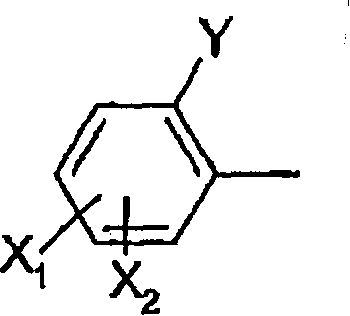

Method used

Image

Examples

Embodiment 1

[0069] Example 1: C.I. Pigment Red 269

[0070] a1) Preparation of Anisbase (Anisbase) diazonium salt solution:

[0071] 2532 g of water were added as an initial charge and at room temperature first 242 g of 3-amino-4-methoxy-N-benzanilide were homogeneously stirred in, precipitated by addition of hydrochloric acid and cooled with 1.5 kg of ice / water to 10°C. During the diazotization of the precipitated hydrochloride with 138 ml of sodium nitrite solution (40%), an easily stirrable anisidine-diazonium solution was finally formed. This solution was filtered off into a receiving vessel after addition of a clarification aid. Excess nitrite is removed by adding sulfamic acid.

[0072] a2) Preparation of buffer for anisidine diazonium salt solution:

[0073] 1884 g of ice / water were added as an initial charge and 502 g of acetic acid were added as well as 614 g of aqueous sodium hydroxide solution, and the temperature was kept at room temperature after the addition of 1 kg of w...

Embodiment 2

[0091] Example 2: C.I. Pigment Red 146

[0092] Steps a)-d) are carried out analogously to Example 1. The pigments obtained after step c) contain anisidine, chloromethoxyaniline, anisidine triazene and naphthol AS below the respective detection limit.

Embodiment 3

[0093] Example 3: C.I. Pigment Red 147

[0094] Steps a)-d) are carried out analogously to Example 1. The pigments obtained after step c) contain anisidine, chloromethoxyaniline, anisidine triazene and naphthol AS below the respective detection limit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com