High current MOS device with avalanche protection and method of operation

A high-current, MOS transistor technology, applied in the semiconductor field, can solve the problems of electric-thermal failure of the device 10, hindering the pure heating limit of the device 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

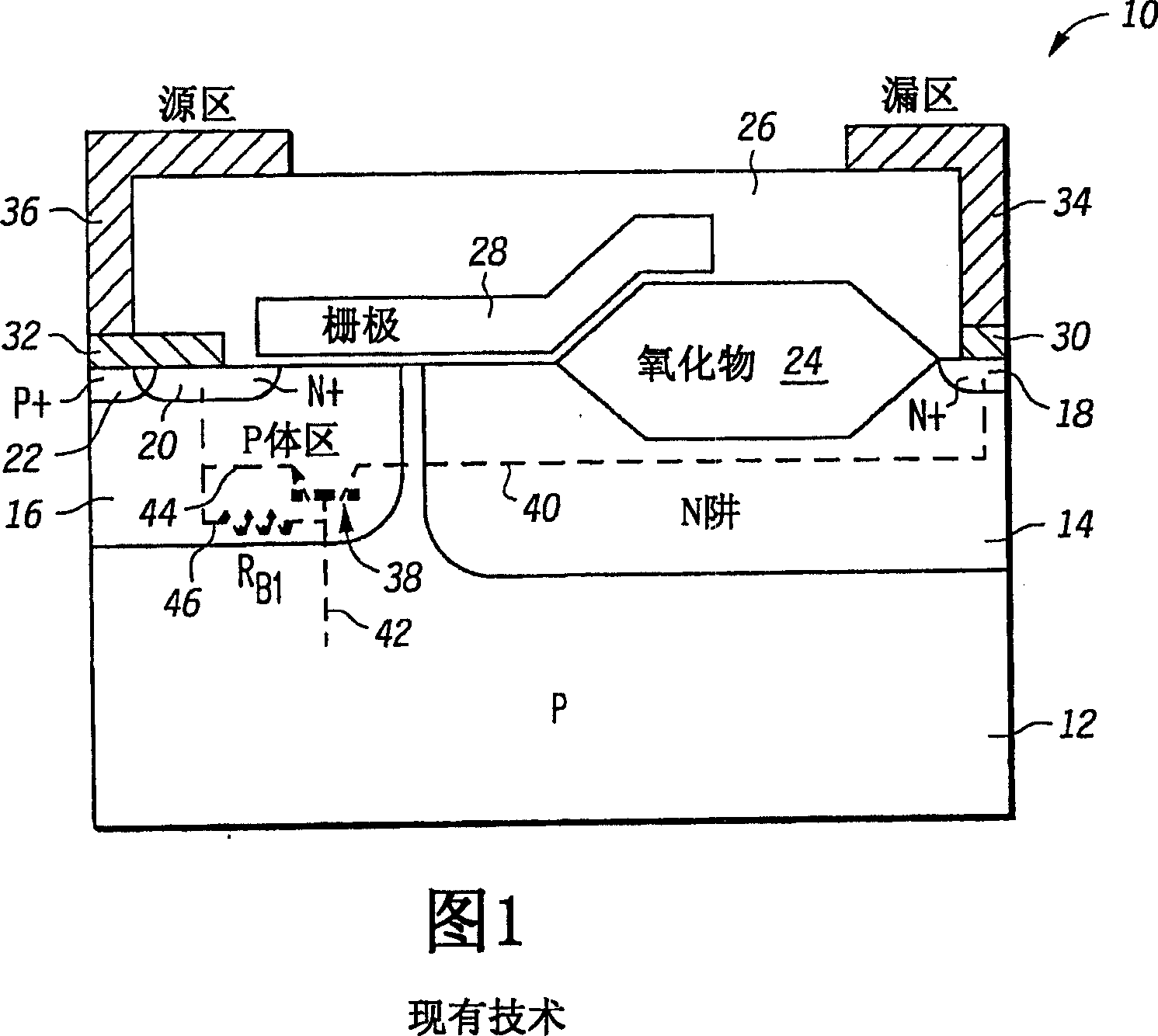

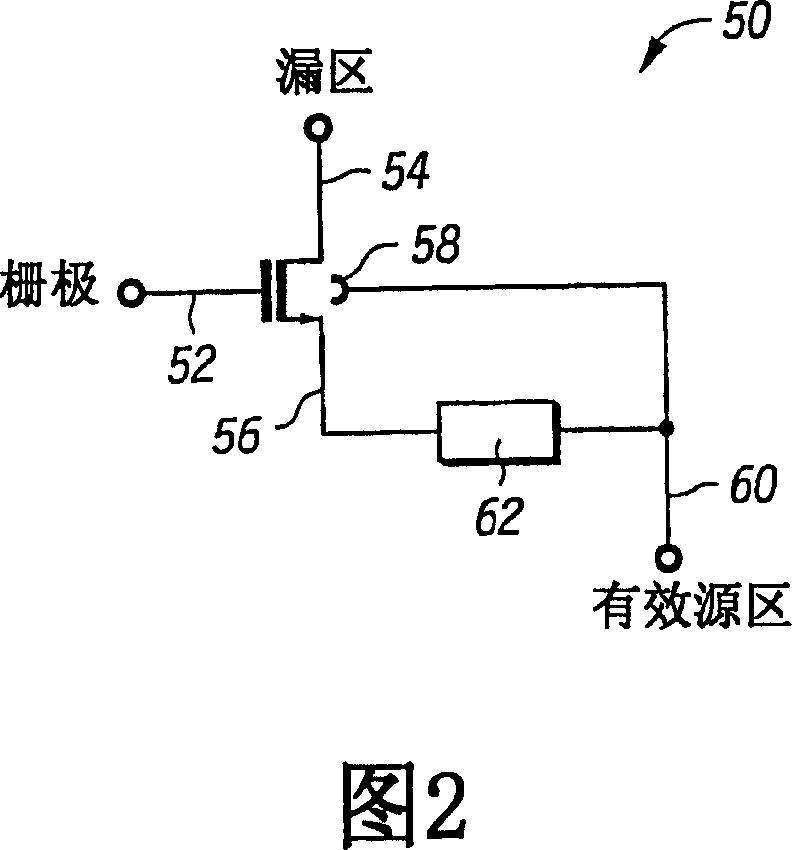

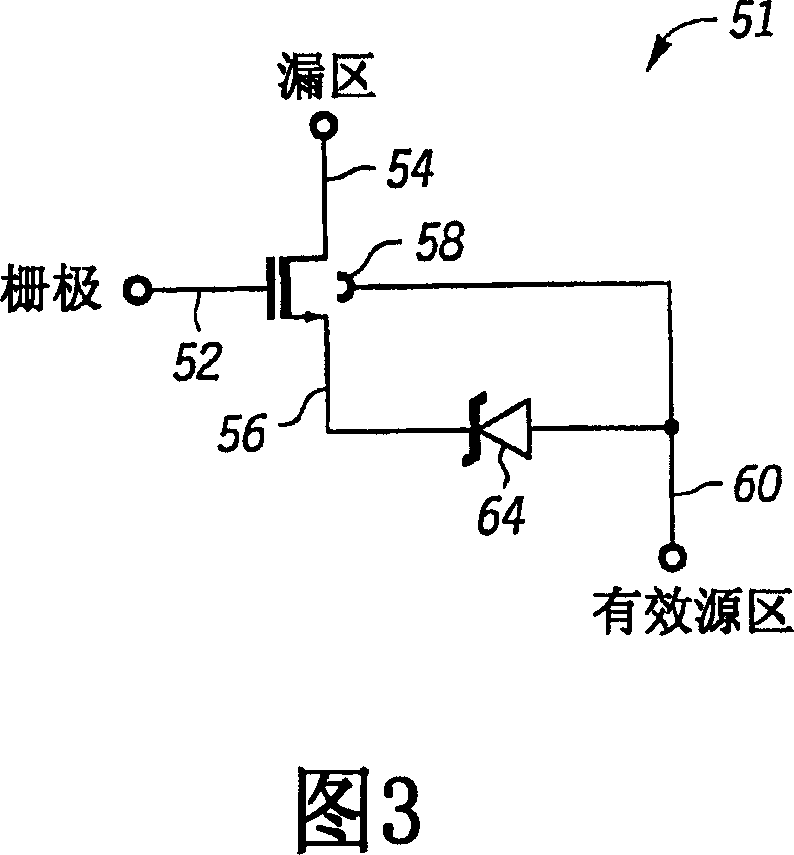

[0019] In high current applications, electron-hole pairs are generated in the drain region of the MOS transistor, causing the inherently parasitic bipolar transistor to destructively turn on. Holes pass through the body region of the MOS transistor, which has an intrinsic resistance, to the source region, which is usually held at a low voltage such as ground. The hole current causes the voltage of the body region which is the base region to rise. This rising base voltage is what causes the parasitic bipolar transistor to turn on. The channel current passes through the impedance between the source region and the body region, and the voltage between the source region and the body region as the emitter region rises, which can greatly reduce the above possibility. When the base voltage increases, it causes the emitter voltage to increase, preventing the parasitic bipolar transistor from turning on.

[0020] Therefore, in order to achieve practical thermal performance of a power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com