Semi-automatic pad winding machine

A semi-automatic, winding machine technology, applied in the direction of engine components, engine seals, mechanical equipment, etc., can solve the problems that the diameter and the number of turns cannot be measured, the tension of the steel belt cannot be adjusted, and the quality of the product is affected. Simple structure, The effect of high production efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

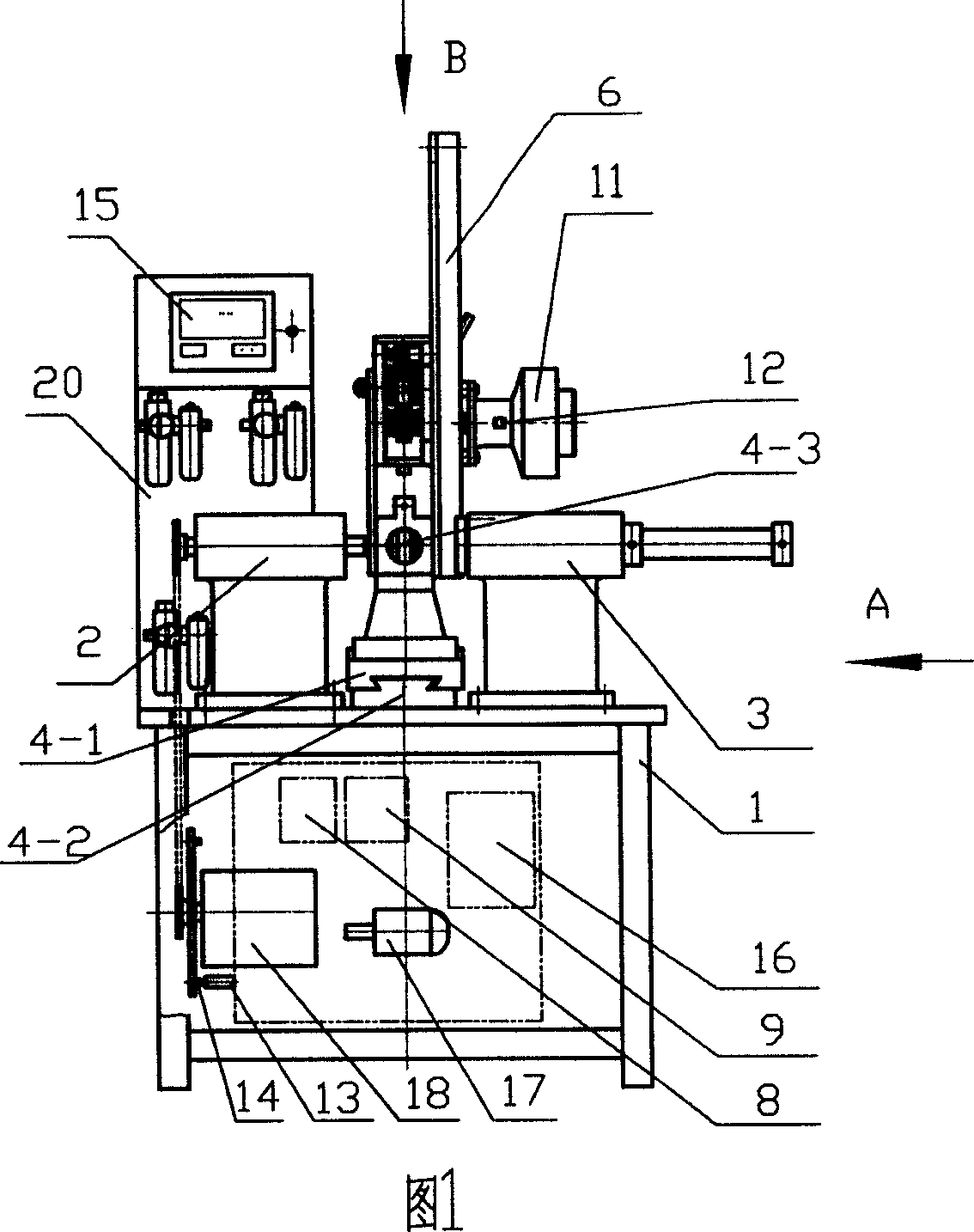

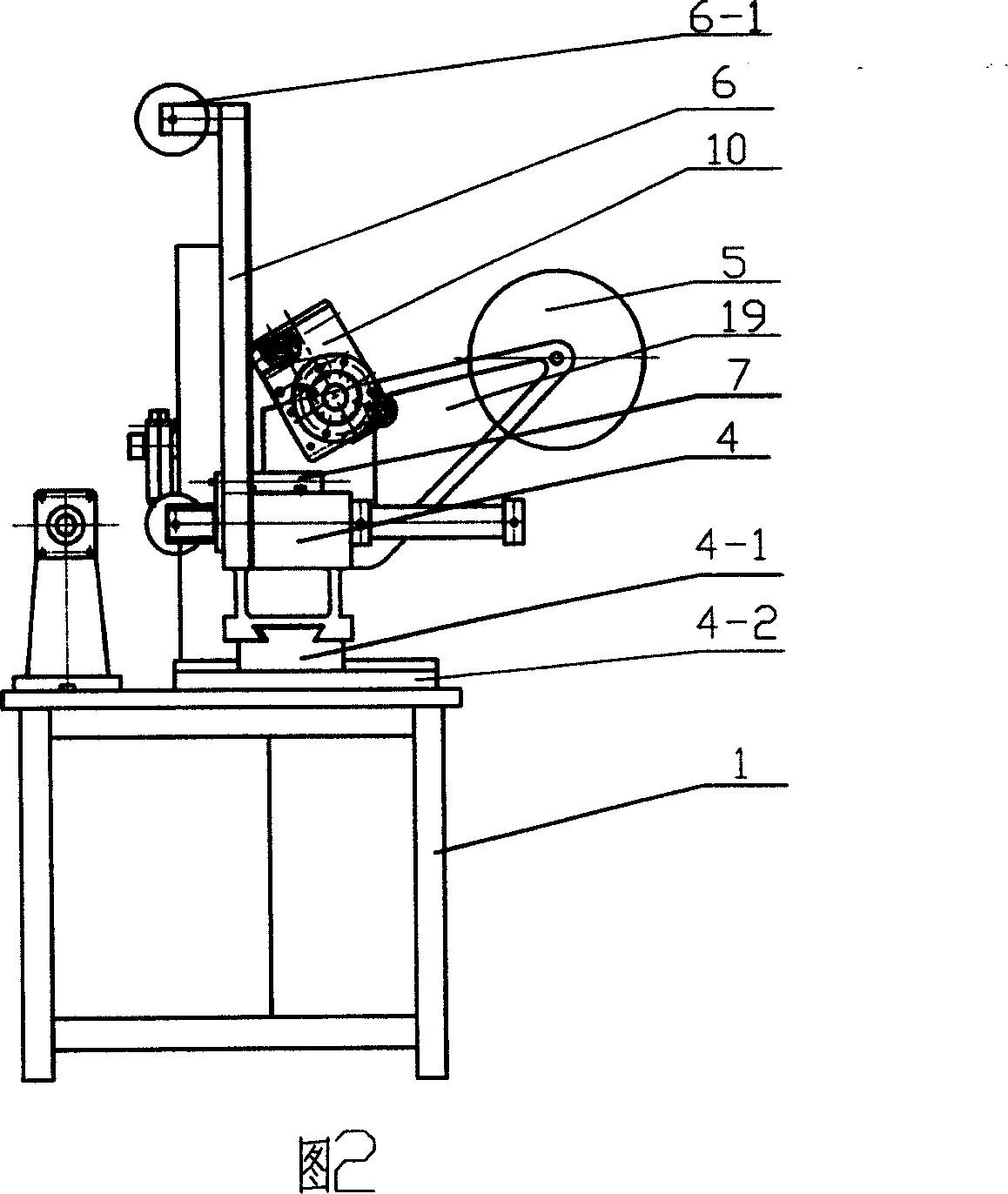

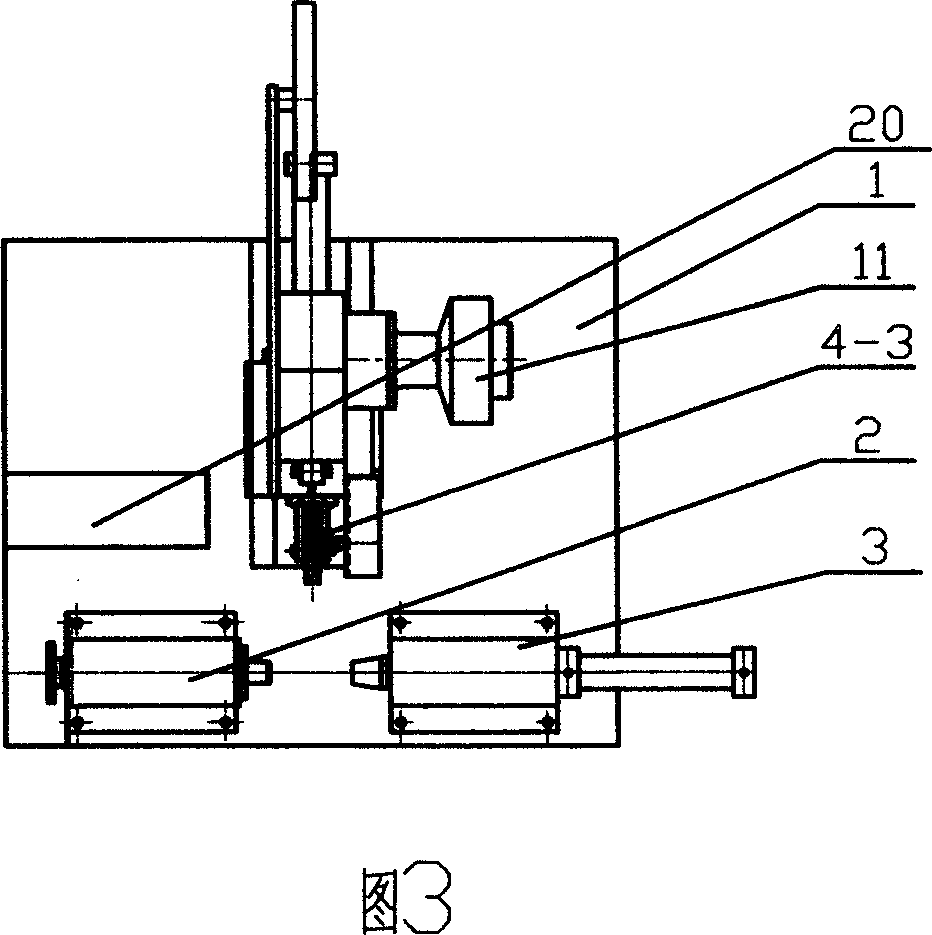

[0017] Embodiment: The semi-automatic gasket winding machine of this example, as shown in Fig. 1, Fig. 2 and Fig. 3, has a frame 1, and a driving device is provided inside the frame 1, and the driving device is a driving motor 17 and a turbine box 18. The turbine box 18 is connected with an angle induction disc 14, and the angle induction disc 14 is synchronously connected with a main shaft part 2 which can be installed with gaskets. Also be provided with push out pressing part 3. The frame 1 is provided with a steel belt pressure wheel part 4, on which a filling belt installation frame 6 is vertically fixed, and the top of the filling belt installation frame 6 is connected with a filling belt installation device 6-1. A connection plate 19 is affixed to the steel belt pressure wheel part 4, and a steel belt placement device 5, a steel belt forming device 10, an air motor 11 and a flow regulating valve 12 are fixedly connected to the connection plate 19, so that the steel belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com