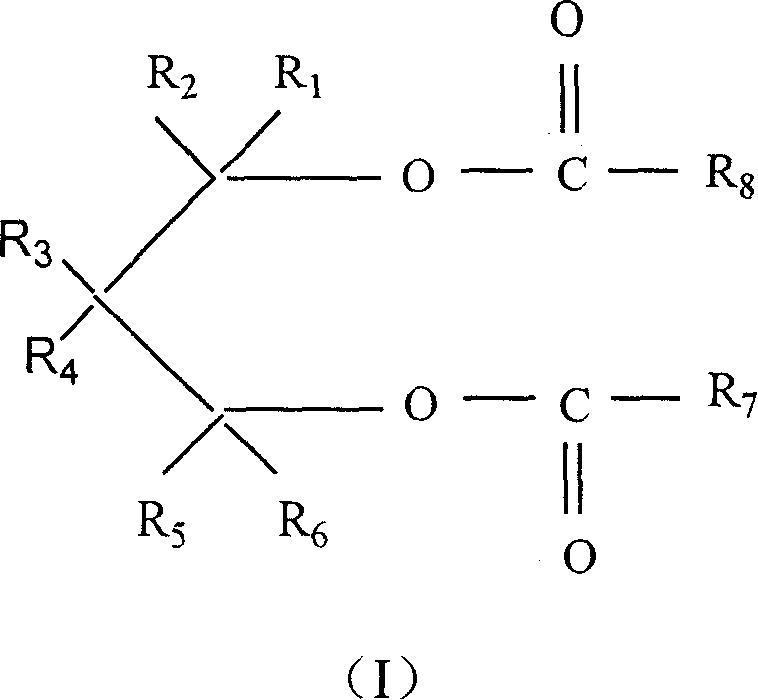

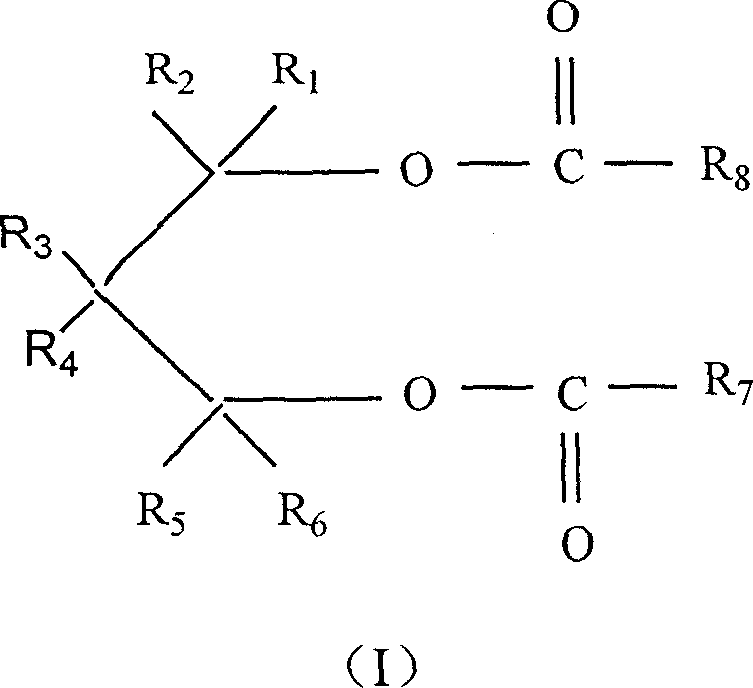

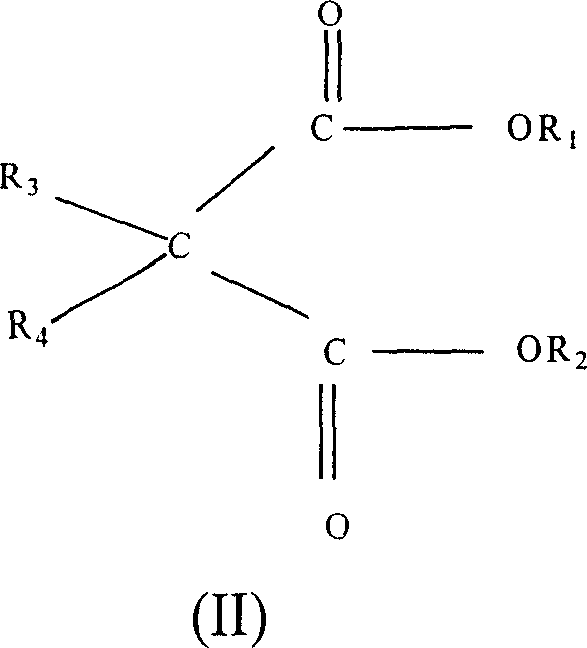

Solid catalyst composition used for olefine polymerization and catalyst thereof

A solid catalyst, a technology for olefin polymerization, applied in the application field of preparing an olefin polymerization catalyst, and can solve the problems of unsatisfactory catalyst activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The preparation of the composite carrier is the same as in Comparative Example 1. The only difference from Comparative Example 1 in the catalyst preparation process is that 0.25 mL of 4-ethyl-3,5-heptanediol dibenzoate and 0.75 mL of di-n-butyl phthalate were added at the same time for electron donation body. Propylene polymerization process is with embodiment 1.

[0076] See Table 1 for the composition of the homogeneous catalyst and some physical parameter tests, and see Table 2 for the test results of the catalyst activity and the performance data of the obtained polypropylene resin.

Embodiment 2

[0078] The preparation of the composite carrier is the same as in Comparative Example 1. During catalyst preparation, the only difference from Comparative Example 1 was the addition of 0.50 mL of 4-ethyl-3,5-heptanediol dibenzoate and 0.50 mL of di-n-butyl phthalate to give electronic body. Propylene polymerization process is with embodiment 1.

[0079] The composition of the solid catalyst and some physical parameter tests are shown in Table 1, and the test results of the catalyst activity and the performance data of the obtained polypropylene resin are shown in Table 2.

Embodiment 3

[0081] The preparation of the composite carrier is the same as in Comparative Example 1. During the preparation of the catalyst, the only difference from Comparative Example 1 was the use of 0.75 mL of 4-ethyl-3,5-heptanediol dibenzoate mixed with 0.25 mL of di-n-butyl phthalate electronic body. Propylene polymerization process is with embodiment 1.

[0082] The composition of the solid catalyst and some physical parameter tests are shown in Table 1, and the test results of the catalyst activity and the performance data of the obtained polypropylene resin are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com