Ball socket joint used in deep sea resource exploiting system mine throwing subsystem

A technology of ball joints and resources, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of joints with large bending moments, failure and damage, and prominent negative effects, so as to achieve safe transportation , High connection strength, fast disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

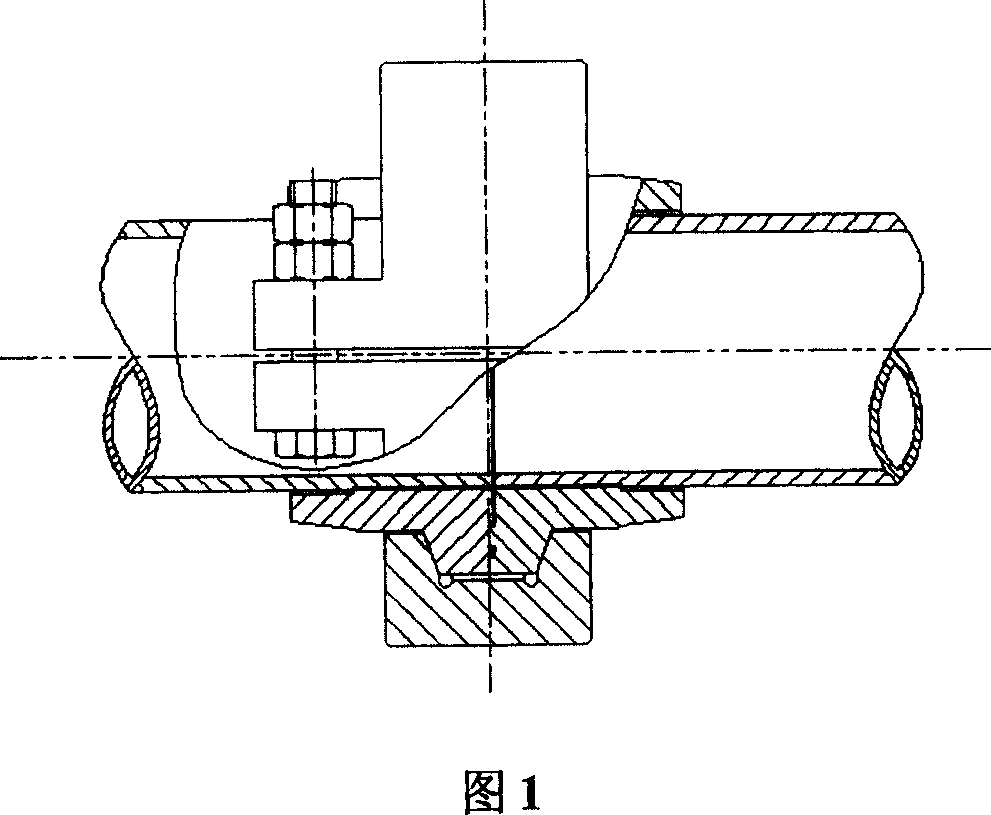

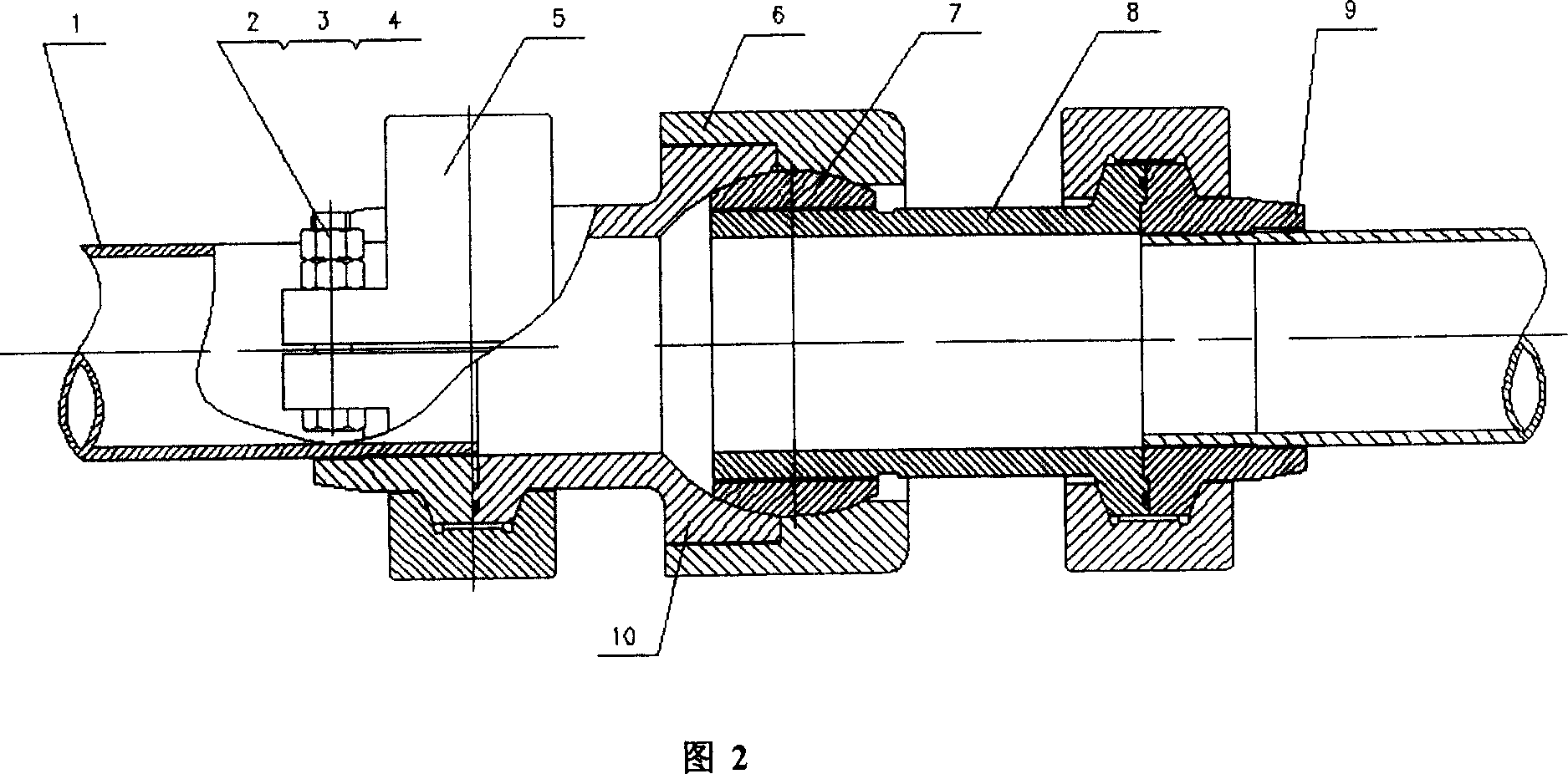

[0017] Hereinafter, the present invention will be described using embodiments in the drawings.

[0018] The ball joint is composed of lifting pipe 1, bolt 2, nut 3, washer 4, snap ring 5, outer ball sleeve 6, ball head 7, lower joint ball end connector 8, joint pipe end connector 9, upper joint ball end Connector 10 constitutes.

[0019] In the sectional view of Fig. 2, in order to make the design result meet multiple requirements, several threaded connections used in the design include: the connection between the end of the mining pipe 1 and the joint pipe end connector, the outer ball sleeve 6 and the upper The connection of the joint ball end connector 10, the connection of the ball head 7 and the lower ball end connector 8, the connection of the joint pipe end connector 9 and the end of the mine lifting pipe. All of the above connections use sealing material. Since the hoisting pipe bears huge axial tension during use, all connections require high processing technology. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com