Panel combining method of liquid crystal display device

A technology of a liquid crystal display device and a combination method, which is applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems of cost loss of panel manufacturers and affect the display effect of the panel, and achieve the effect of weakening the mura phenomenon and dispersing the bonding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Please refer to FIG. 4 , FIG. 5A and FIG. 5B at the same time. In this embodiment, the process of fabricating photoresist-type spacers on the color filter film substrate is taken as an example to illustrate the technical features of the present invention.

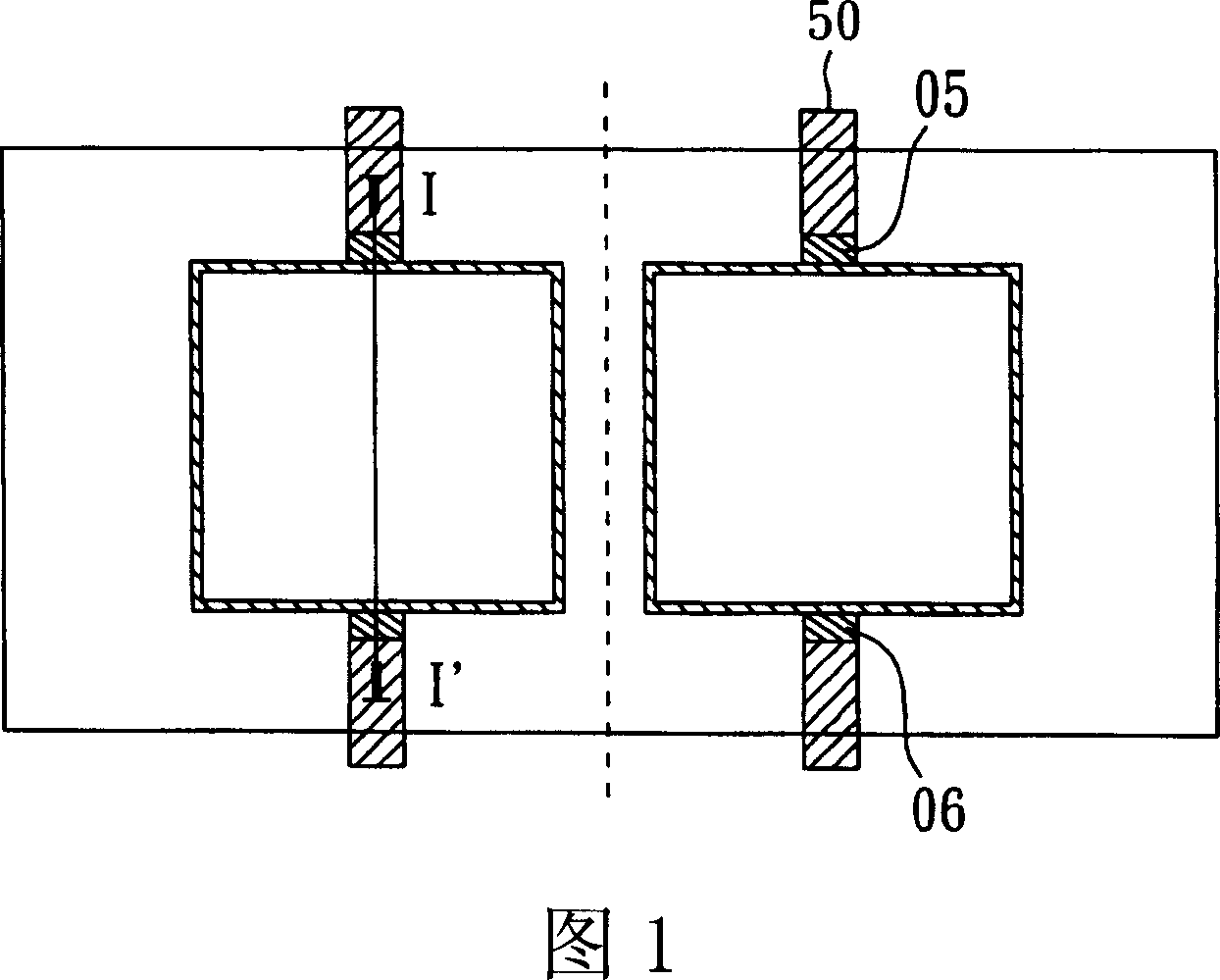

[0046] First define the size of the required color filter film on a glass substrate 00, as shown in Figure 4, the dotted line on one of the large substrates 00 is to schematically separate the areas of two color filter films 100, 200, in A display area 110 and a non-display area 120 are further defined on a single color filter film 100, and a contact area 130 of a sealant is left at the boundary between the display area 100 and the non-display area 120, so as to facilitate contact with a TFT in the subsequent process. Adhesive bonding of substrates.

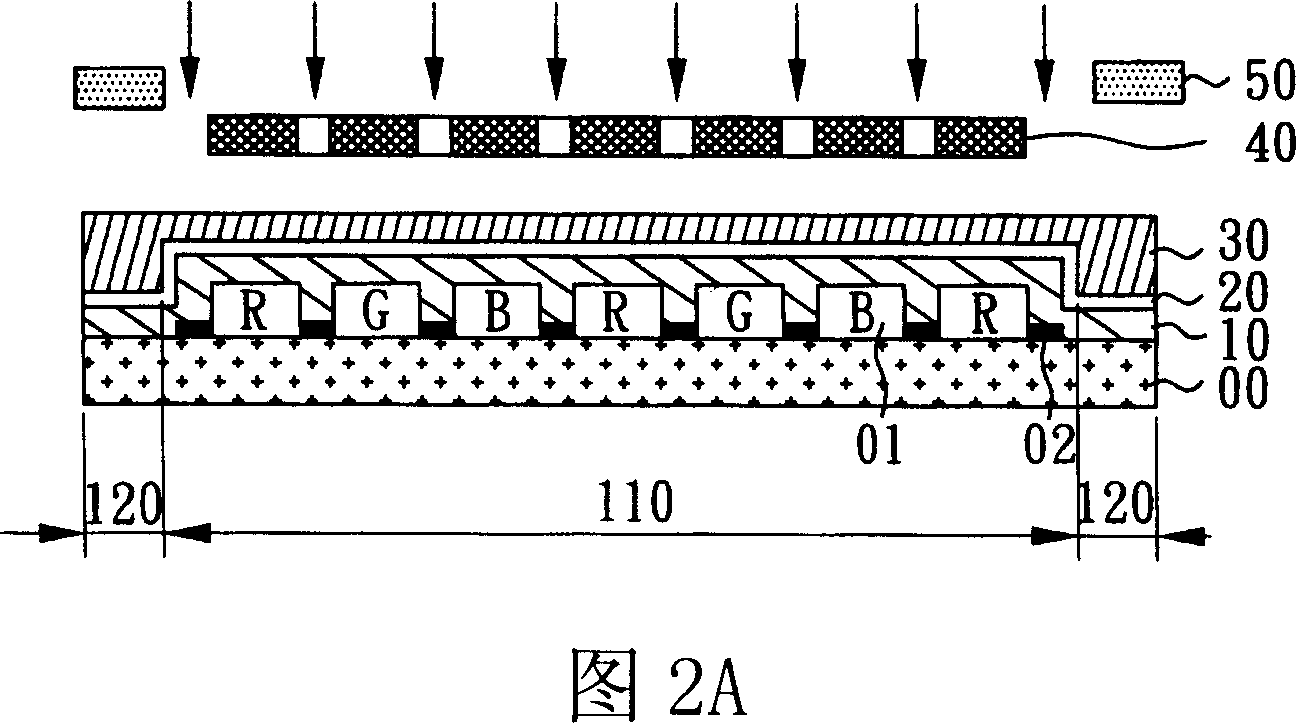

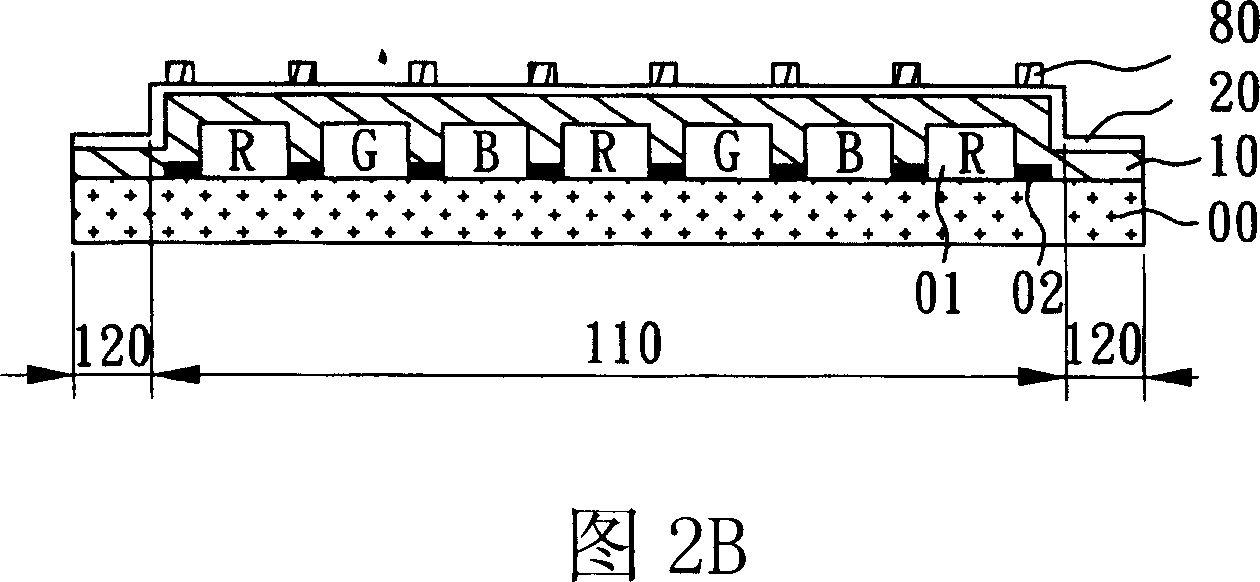

[0047] Please refer to FIGS. 5A and 5B for the cross-sectional view of the line segment I to I' in the region of the color filter film 100. In FIGS.

[0048] Please refe...

Embodiment 2

[0053] In addition to the method described in Embodiment 1, in which the spacer 90 is formed in the non-display region 120 on the CF substrate 00, this embodiment also uses FIG. 7 to illustrate another situation, which can also achieve the purpose of not causing mura in the forbidden region.

[0054] As shown in FIG. 7, a spacer 91 is formed on the outer edge of the original exposure forbidden area 05. The steps for forming the spacer 91 are roughly the same as those described in Embodiment 1, except that the mask patterns used are different. In this example a U-shaped washer is shown, and the mask used will suffice with the corresponding pattern.

[0055] In the above-mentioned embodiment, when the negative photoresist is used for exposure and development, the cover plate that originally covered the gap in the forbidden area is removed, and a large area is directly formed in the forbidden area where no photoresist-type spacers were originally formed. At the same time, other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com