Wire grid polarizer and manufacturing method of the same

A technology of wire grid polarization and manufacturing method, which can be used in polarization elements, diffraction gratings, nonlinear optics, etc., and can solve the problem that visible light cannot obtain sufficient polarization degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] With reference to the embodiments of the present invention, (1) the wire grid polarizing plate of the present invention, (2) the method for obtaining the resin matrix having lattice-shaped protrusions of the present invention, and (3) the wire grid polarizer of the present invention The sequence of the sheet manufacturing method will be described in detail.

[0036] (1) Wire grid polarizer of the present invention

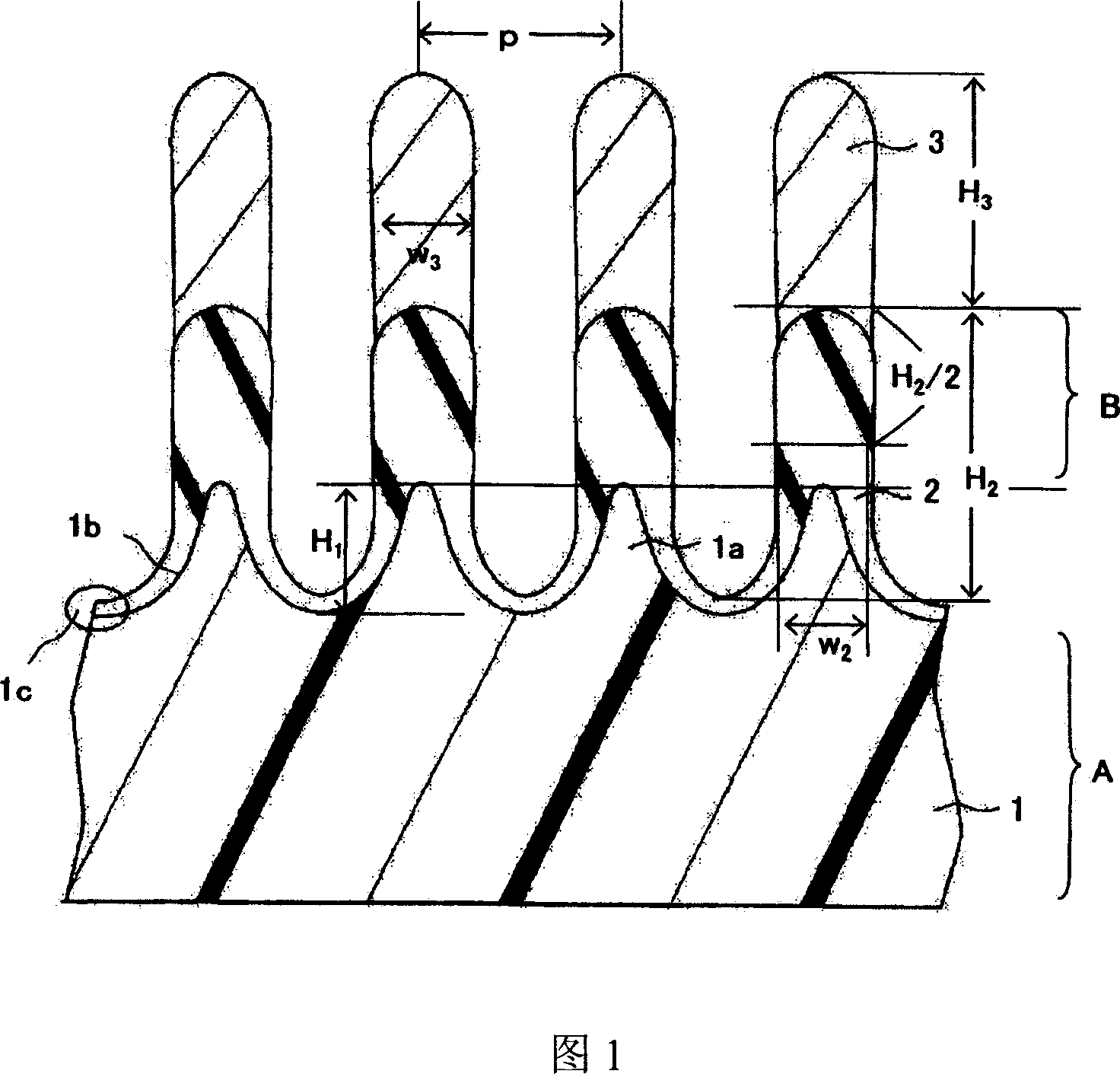

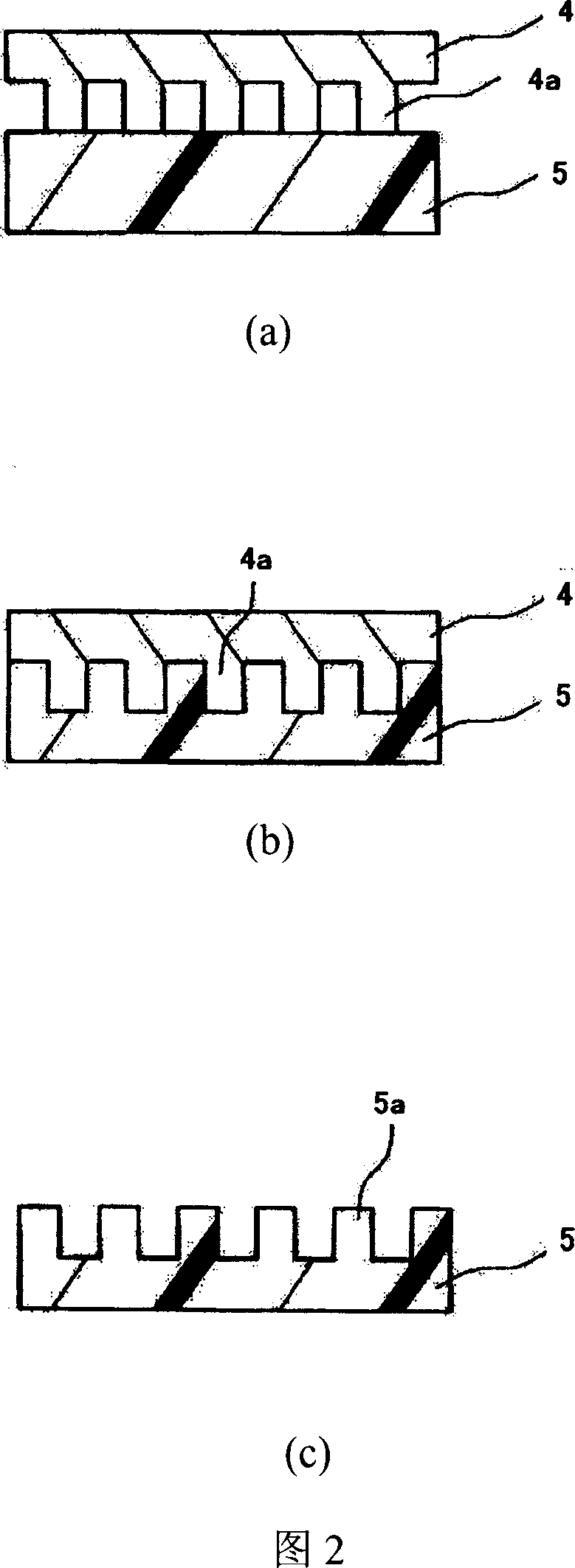

[0037] FIG. 1 is a schematic cross-sectional view showing a part of a wire grid polarizing plate according to an embodiment of the present invention. The wire grid polarizing plate shown in FIG. 1 is mainly composed of a resin substrate 1 (hereinafter also referred to as resin substrate 1) having a lattice-shaped convex portion, and a lattice-shaped convex portion 1a (hereinafter also referred to as convex portion 1a) arranged to cover the resin substrate. Part 1a) and at least a part of the side surface 1b are composed of a dielectric layer 2 and a metal w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com