Manufacture method for diode light-emitting device and its structure

A technology for a light-emitting device and a manufacturing method, which is applied to the manufacturing of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of complex manufacturing process and low heat dissipation efficiency of packaging structure, and achieves improved heat dissipation efficiency and increased air tightness. , the effect of good heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

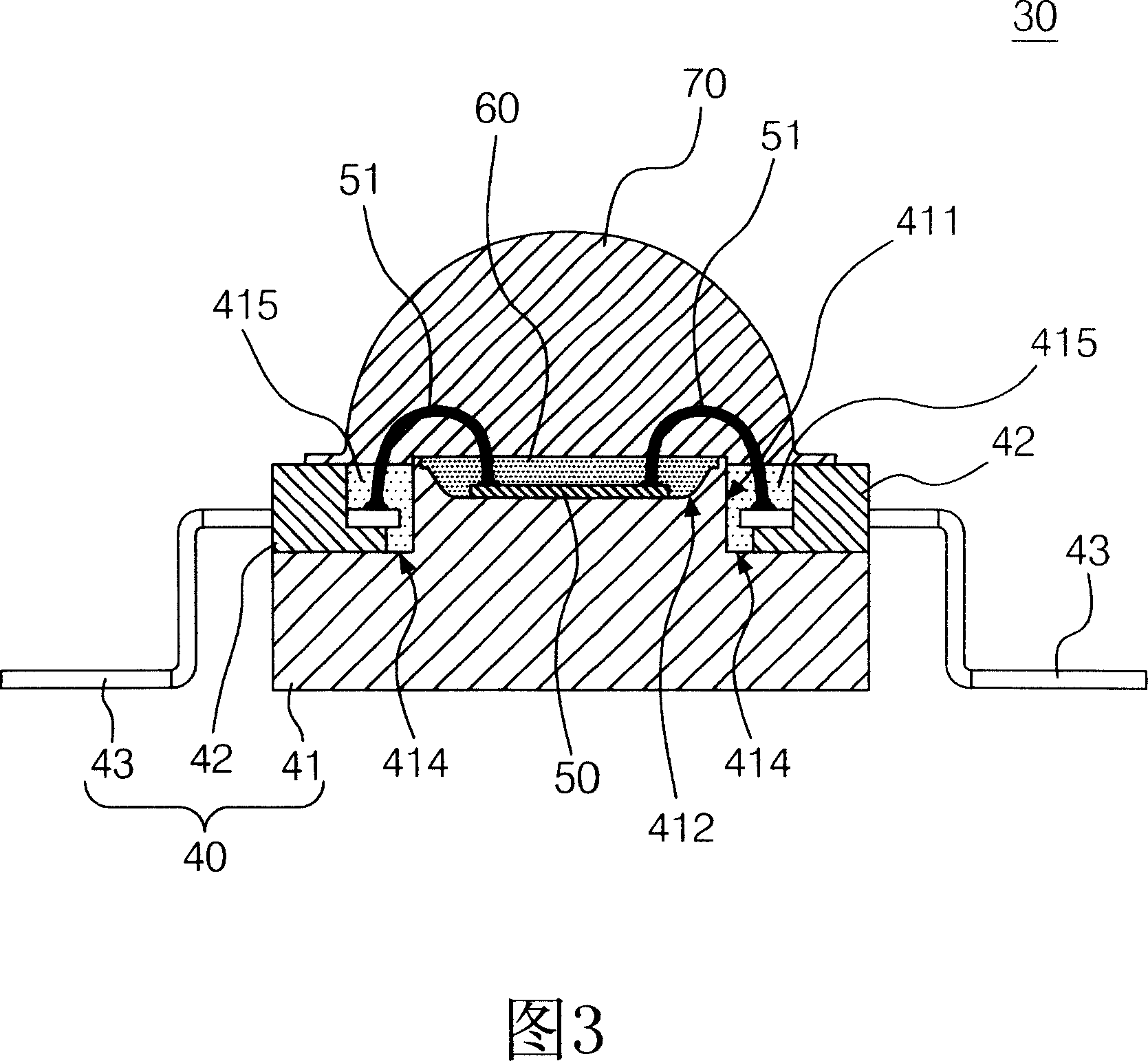

[0091] In order to further illustrate the purpose, structural features and functions of the present invention, the detailed descriptions are as follows in conjunction with relevant embodiments and accompanying drawings:

[0092] The present invention is a method for manufacturing a diode light-emitting device 30 and its structure, wherein the structure of the diode light-emitting device 30 is to use a metal material with good thermal conductivity to manufacture the body 41, 41' of the diode light-emitting device 30, so as to greatly increase the heat dissipation area , so that the diode chip 50 of the diode light emitting device 30 can obtain a better heat dissipation effect during operation.

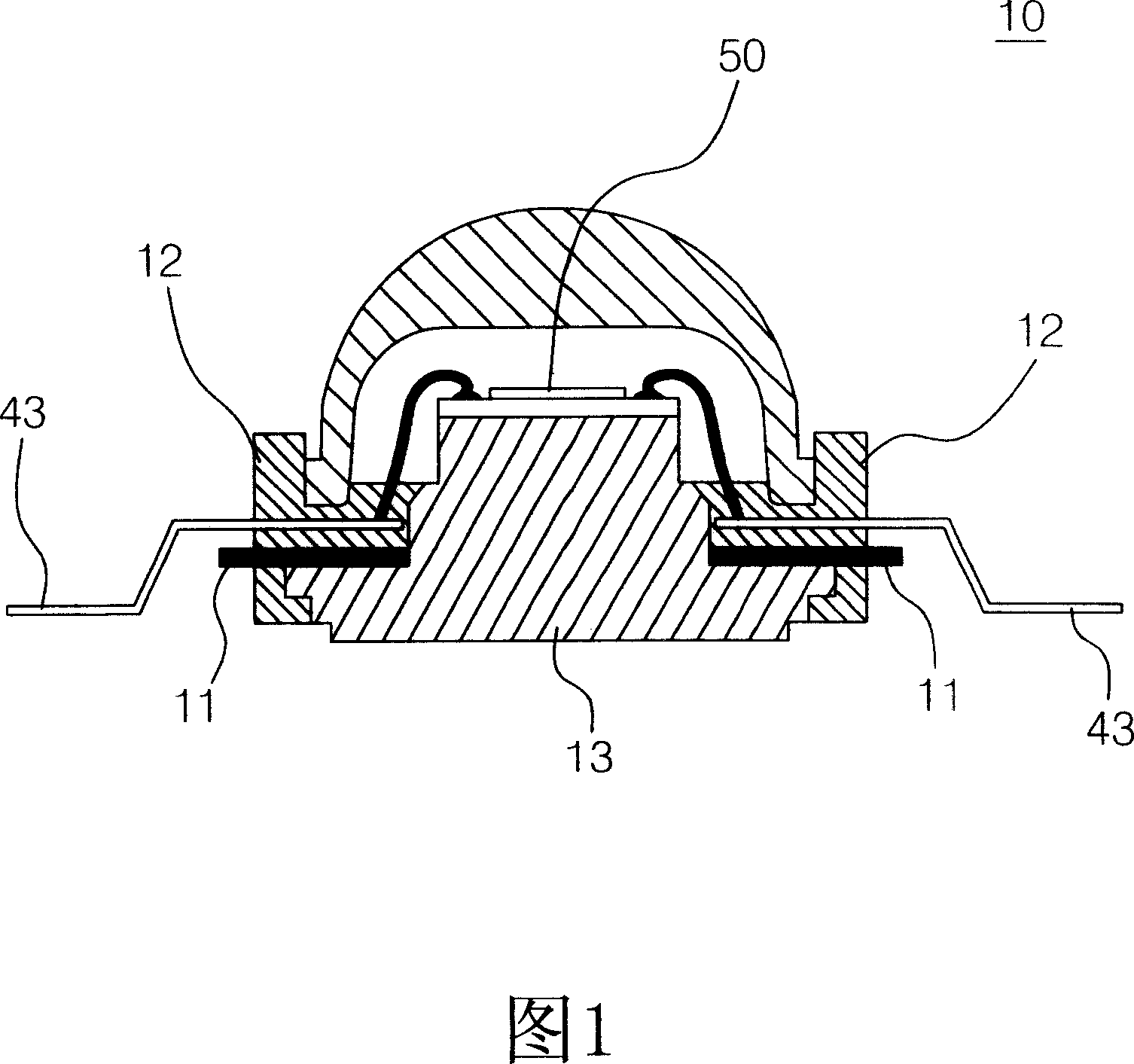

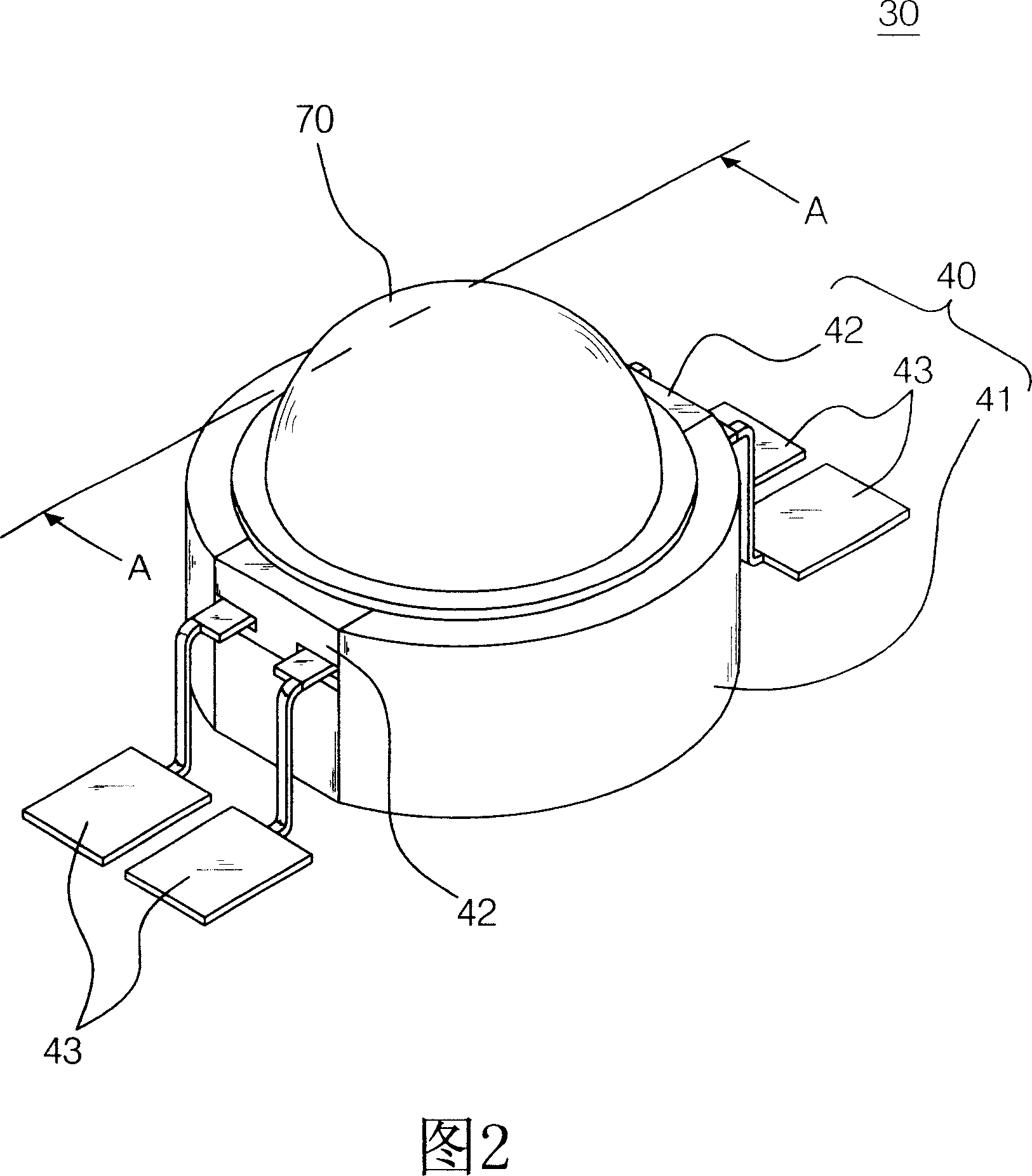

[0093] FIG. 2 is a stereoscopic implementation diagram of a diode light emitting device 30 of the present invention. As shown in FIG. 3 , it is a cross-sectional implementation diagram of a diode light emitting device 30 of the present invention along the line A-A of FIG. 2 . The diode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com