Hologram recording material and hologram recording medium

一种全息照相、记录材料的技术,应用在全息图记录材料、记录载体材料、记录信息存储等方向,能够解决不能进行记录、流动性降低、记录材料漏出等问题,达到高灵敏度、高折射率变化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

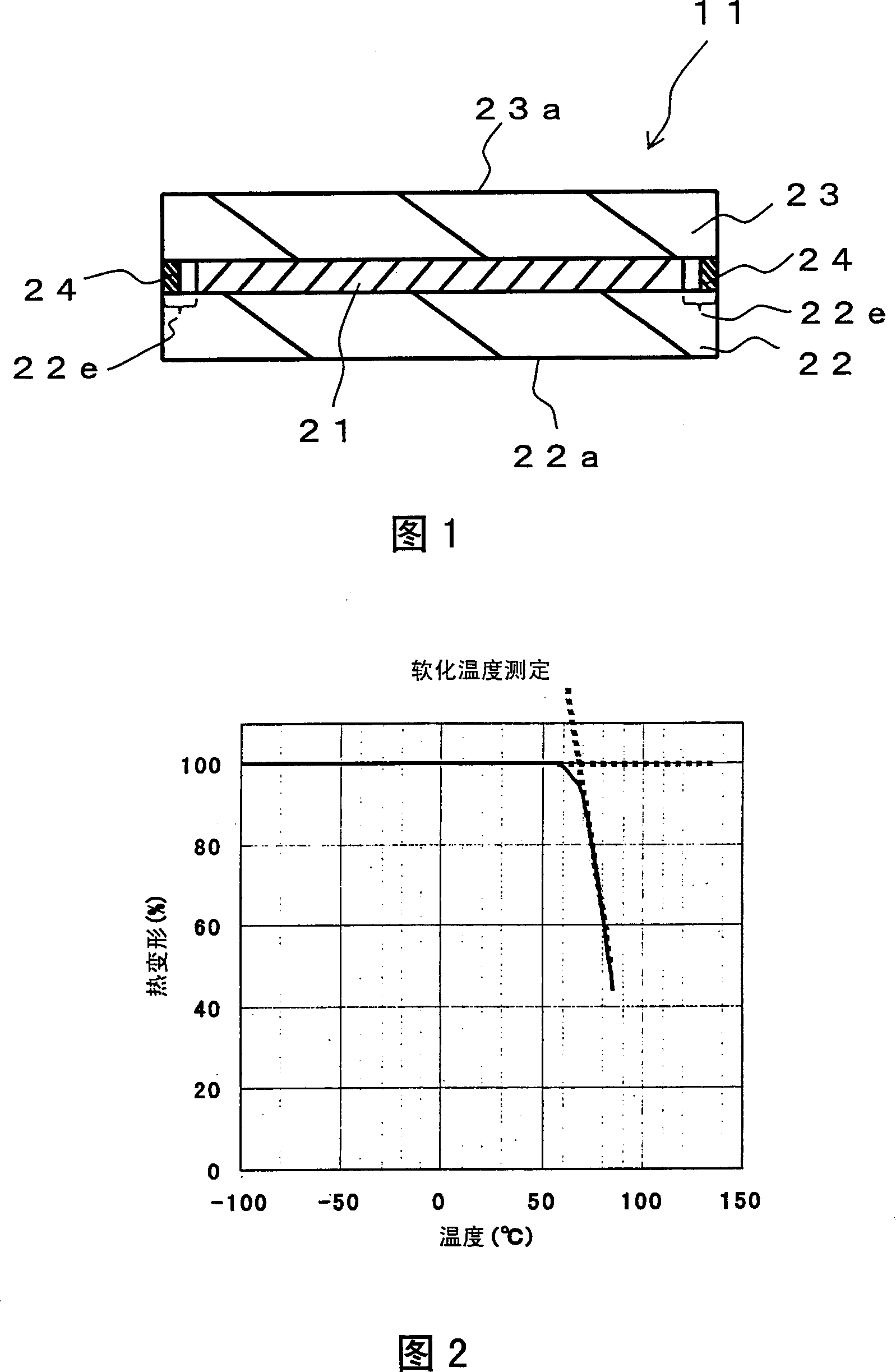

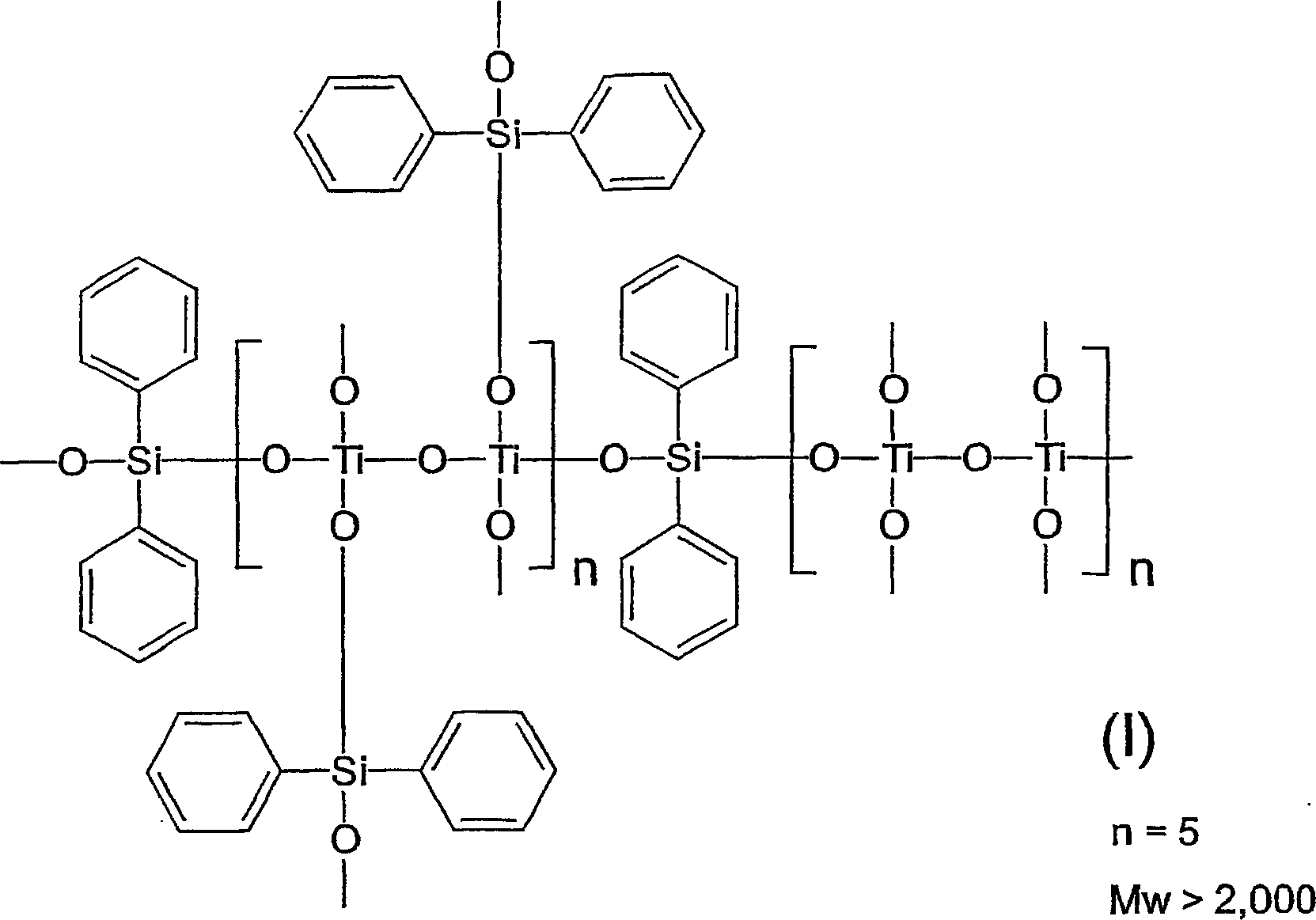

[0084] A holographic recording material was produced by the sol-gel method using diphenyldimethoxysilane and a titanium butoxide polymer represented by the following structural formula in the following steps.

[0085]

[0086] (Synthesis of matrix material)

[0087] 7.8 g of diphenyldimethoxysilane and 7.2 g of a titanium butoxide polymer (manufactured by Nippon Soda, B-10) were mixed in 40 mL of a tetrahydrofuran solvent to prepare an alkoxide solution. That is, the molar ratio of Si and Ti is 1:1.

[0088] A solution consisting of 2.1 mL of water, 0.3 mL of 1N aqueous hydrochloric acid solution, and 5 mL of tetrahydrofuran was dropped into the alkoxide solution at room temperature while stirring, and the stirring was continued for 2 hours to carry out a hydrolysis reaction. Thus, a sol solution A containing an organometallic compound of Si:Ti:phenyl = 1:1:2 (molar ratio) was obtained.

[0089] (photopolymerizable monomer)

[0090] Polyethylene glycol diacrylate (manufa...

Embodiment 2

[0112] A holographic recording material was obtained in exactly the same manner as in Example 1 except that the ratio of the base material (as a non-volatile component) was 46% by weight relative to the entire holographic recording material. Furthermore, a hologram recording medium is produced.

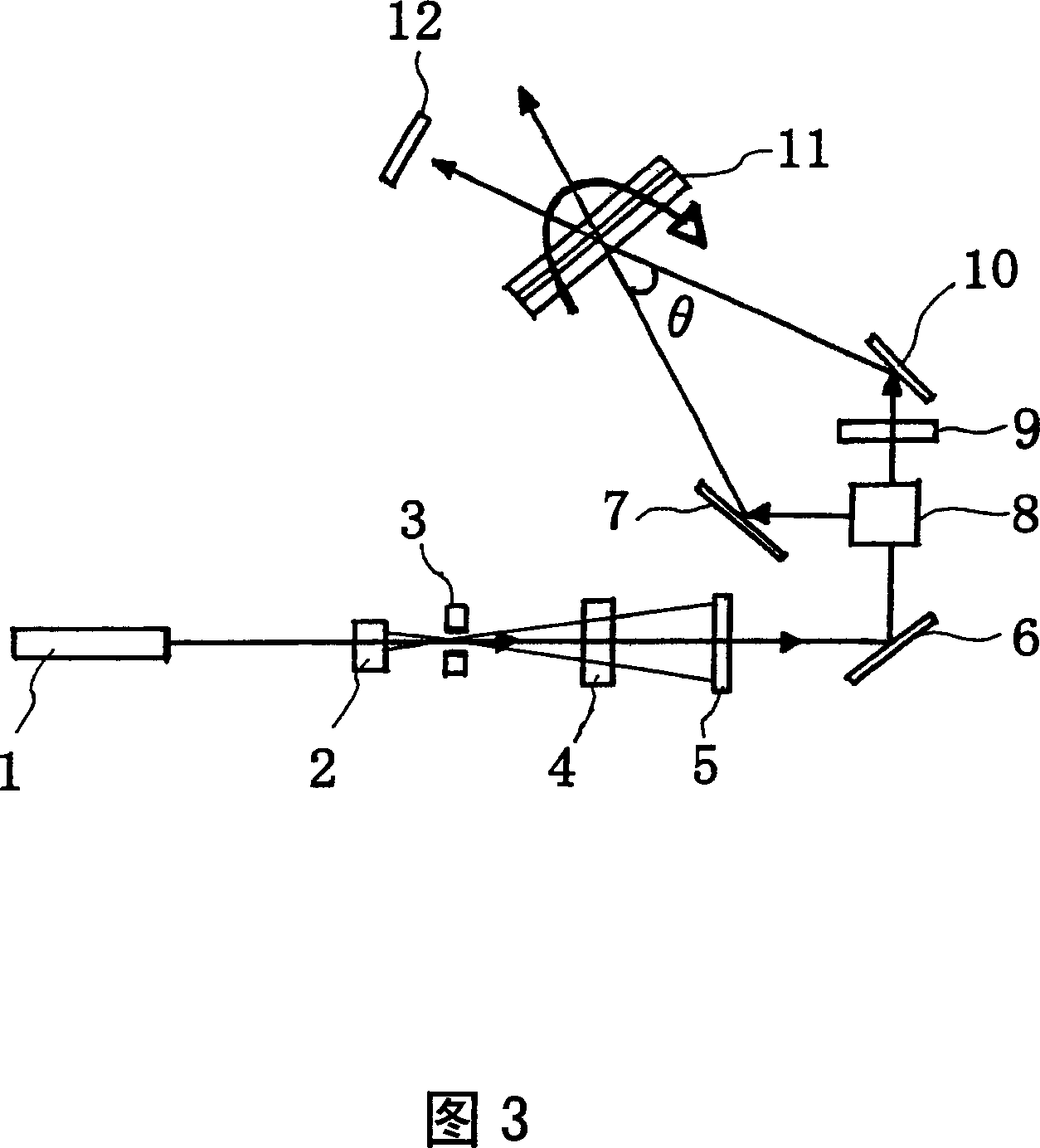

[0113] The softening temperature of the holographic recording material layer was -16°C.

[0114] For the holographic recording medium sample of embodiment 2, it can be recorded without pre-exposure treatment, and the initial recording sensitivity is 0.002 [M# / (m) / (cm 2 )], lower than the sensitivity value of the sample of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com