Producing method of dielectric powder, composite electronic part and producing method thereof

A technology of composite electronic components and manufacturing methods, which is applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, electrical components, etc., and can solve the problems of poor sinterability, reliability deterioration, and difficulty in thinning the dielectric layer, etc. problems, achieve high reliability and improve sinterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] In this example, a dielectric powder and a dielectric green sheet were produced, and the obtained dielectric powder and dielectric green sheet were respectively evaluated.

[0137] First, prepare TiO as the main component raw material constituting the dielectric powder 2 , CuO, NiO, and MnCO as a secondary component raw material 3 , each raw material is wet-mixed to obtain a mixed powder. Wet mixing was carried out by adding pure water to the prepared main component raw materials and auxiliary component raw materials, putting them in a medium made of an oxidation pick and mixing them by ball milling for 16 hours.

[0138] The addition amount of each main component raw material is, TiO 2 : 92mol%, CuO: 3mol%, NiO: 5mol%, MnCO as a subcomponent raw material 3 It is 1% by weight for the main component raw material. In addition, in this example, as TiO 2 raw material, using SiO 2 The content by weight ratio is 20ppm of raw materials.

[0139] Then, the mixed powder o...

Embodiment 2

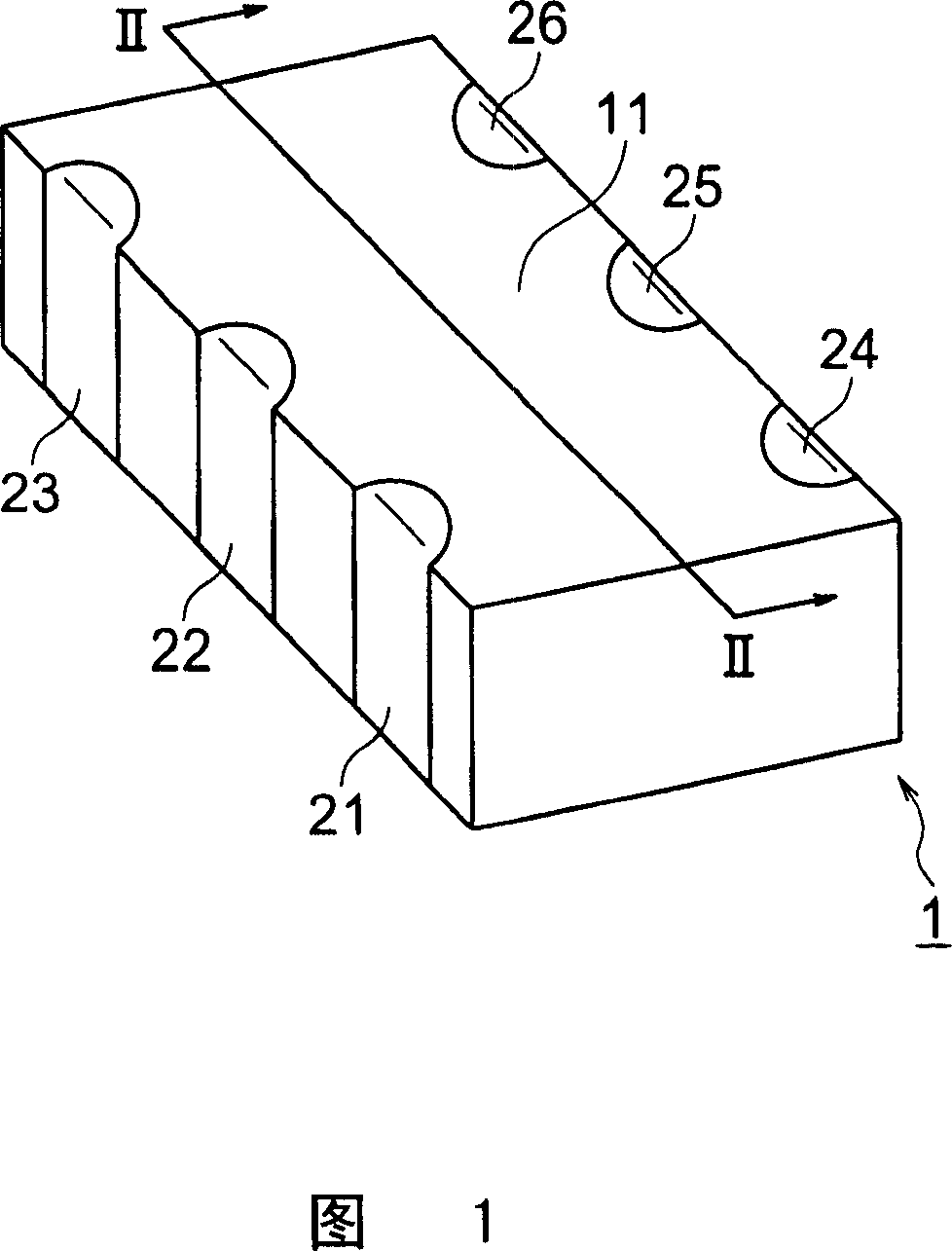

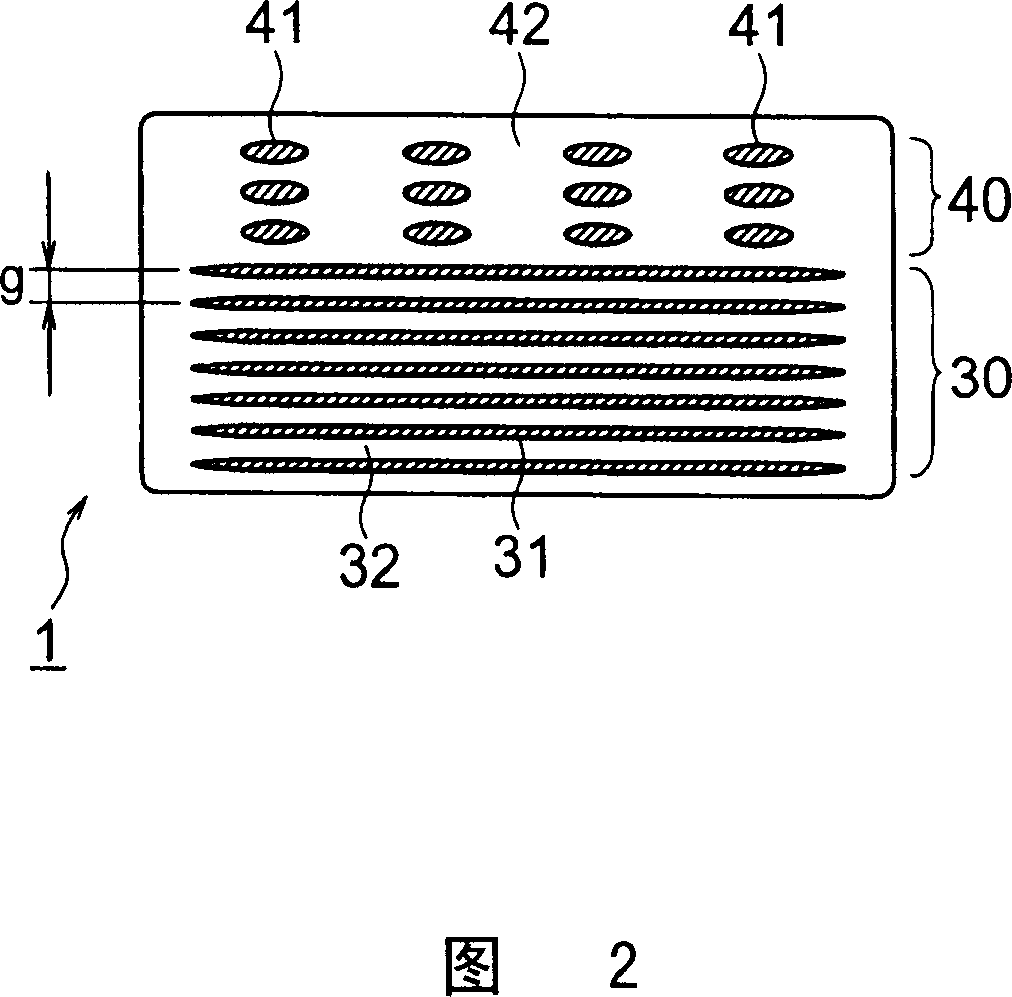

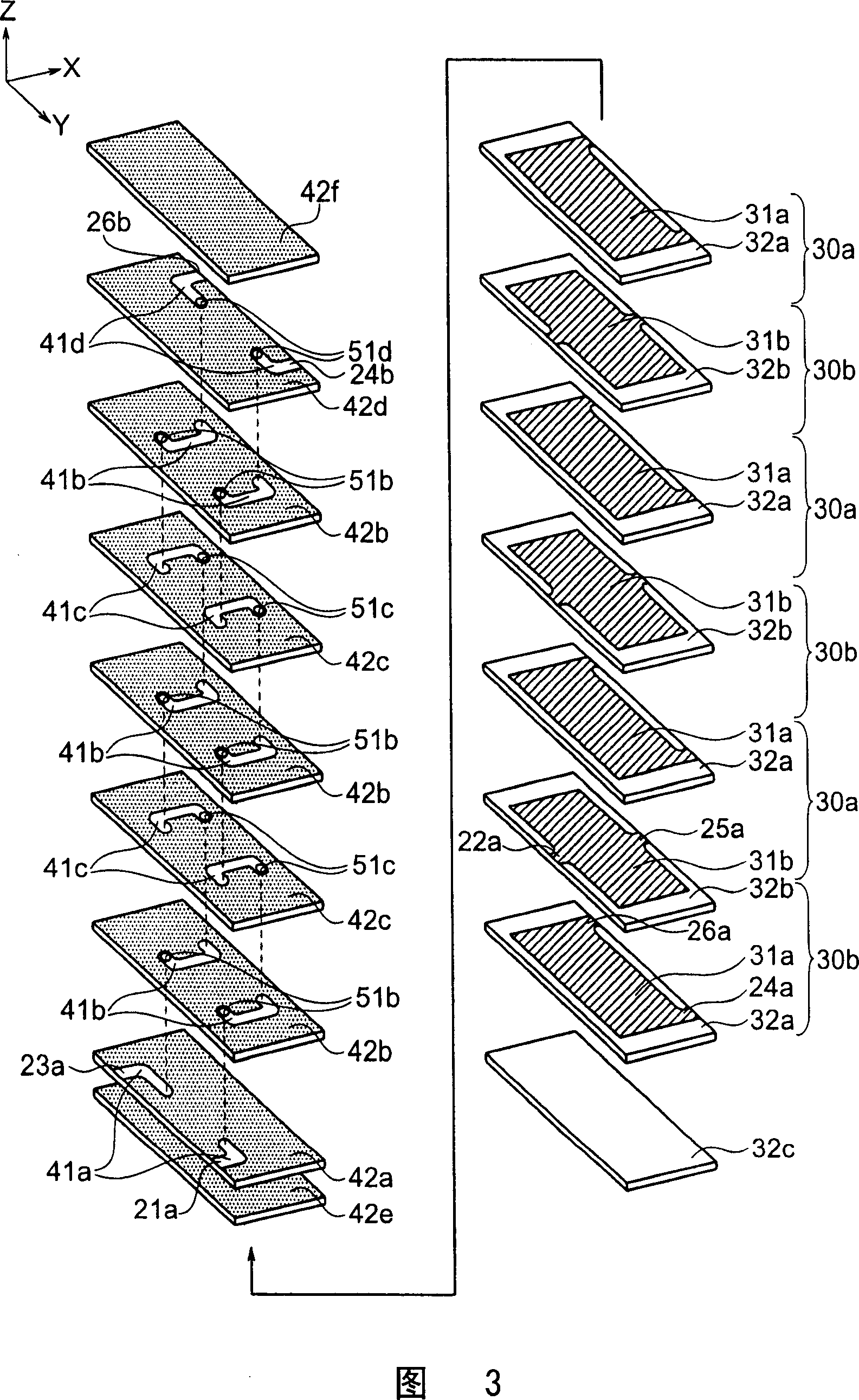

[0155] In Example 2, using the dielectric green sheet produced in Example 1, a multilayer filter having the configuration shown in FIGS. 1 to 3 was produced by the following method.

[0156] That is, first, a predetermined electrode pattern was printed on the dielectric green sheet produced in Example 1 using a paste for internal electrodes containing silver as a main component, thereby producing a dielectric green sheet with an electrode pattern. In this example, the internal electrode patterns were the patterns shown in FIG. 3, and a plurality of dielectric green sheets having electrode patterns were produced.

[0157] Next, a magnetic body green sheet is produced.

[0158] First prepare NiO, CuO, ZnO, and Fe as raw materials for magnetic material powder 2 o 3 , mixing these raw materials, followed by sintering and pulverization to prepare magnetic material powder. In addition, the compounding quantity of each raw material is NiO: 25 mol%, CuO: 11 mol%, ZnO: 15 mol%, and ...

reference example 1

[0176] Except when making dielectric powder, as the main component raw material TiO 2 The raw material is TiO 2 Raw materials, using SiO-containing 2 219ppm TiO by weight ratio 2 Except that, a dielectric powder was produced in the same manner as in Example 1, and then a dielectric green sheet was produced in the same manner as in Example 1. Then, a multilayer filter was produced by the same method as in Example 2 using the obtained dielectric green sheet, and evaluation was performed in the same manner as in Example 2. In Table 1, the results of IR (insulation resistance) and average lifetime are shown. Also, in Reference Example 1, the thickness of the dielectric layer 32 was 15 μm.

[0177] middle sintered

with or without

jet crushed

with or without

TiO 2 raw material

SiO 2 content

[ppm]

IR

[Ω]

average life expectancy

[h]

Example 2

have

have

20

9.8×10 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com