Pd(0) Gn-PAMAM mesoporous catalyst in use for hydrogenation reaction of unsaturated hydrocarbon, and preparation method

A hydrogenation reaction, unsaturated technology, applied in the direction of organic compound/hydride/coordination complex catalyst, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc., can solve the difficulty of catalyst recovery and reuse, etc. problems, to achieve the effect of convenient recycling and stable catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

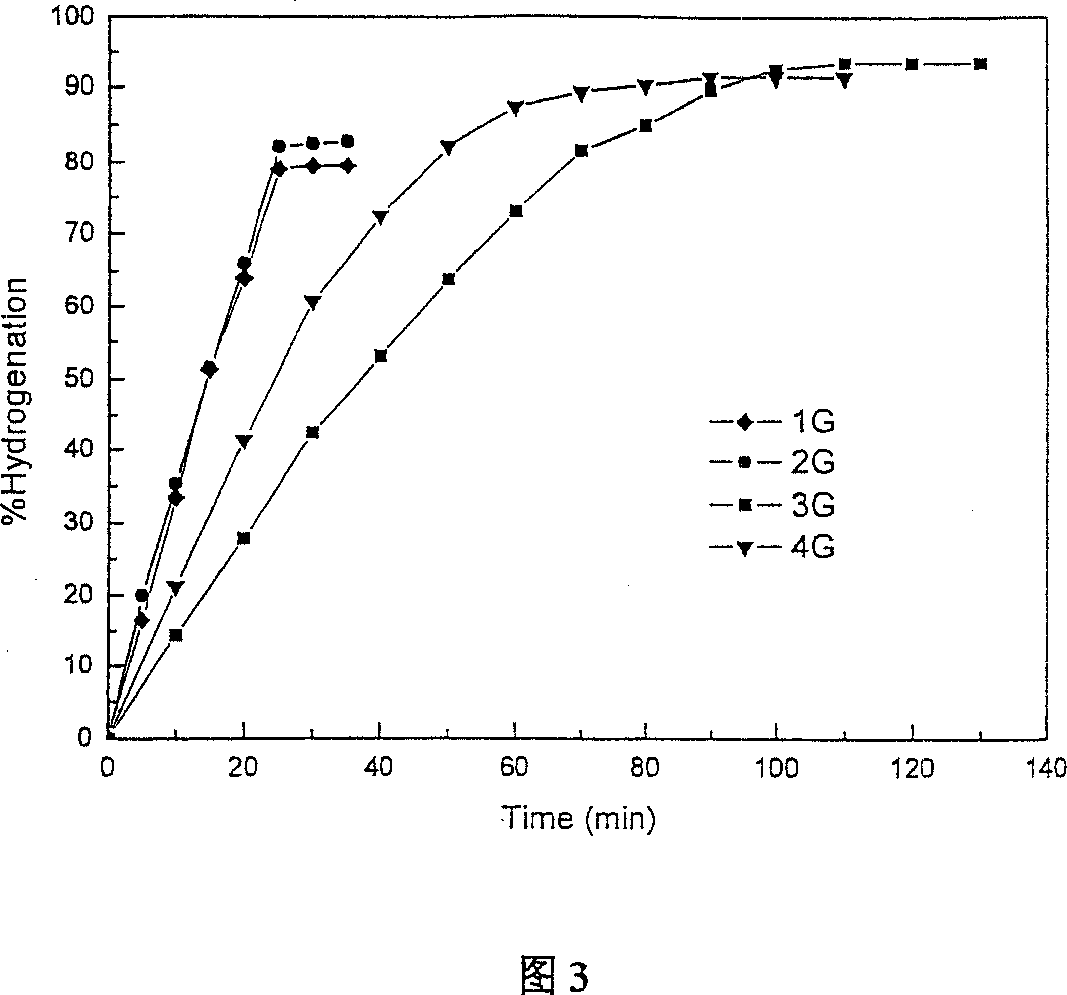

Embodiment 1

[0025] Weigh 0.01 g of the catalyst Pd(0)-G1-PAMAM-SBA-15, add it into a 100 ml three-necked flask containing 50 ml of methanol and water, and cool it with circulating water. The mixture was stirred at room temperature for 30 minutes under the condition of feeding hydrogen, then 10 mmol of allyl alcohol was added, and the reaction was started to be timed. Samples were taken at regular intervals for quantitative analysis until the end of the reaction. When the reaction was finished, the TOF value reflecting the performance of the catalyst was 2185, the conversion rate of propylene alcohol in the solution was 100%, and the selectivity to propylene alcohol was 79.0%.

Embodiment 2

[0027] Weigh 0.01 g of catalyst Pd(0)-G2-PAMAM-SBA-15, add it into a 100 ml three-neck flask containing 50 ml of methanol and water, and cool it with circulating water. Reaction process and operating steps are the same as example 1. When the reaction time is 25 minutes, TOF=2266, the conversion rate of propylene alcohol is 100%, and the selectivity to propylene alcohol is 82.0%.

Embodiment 3

[0029] Similarly, the catalyst in Example 1 was replaced with Pd(0)-G3-PAMAM-SBA-15, and other reaction processes and operating steps remained unchanged. When the reaction was finished, TOF=711, the conversion rate of propylene alcohol was 100%, and the selectivity to propylene alcohol was 93.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com