Method for fine adjusting amount of feed of boring cutter tool, and adjustment device

A technology of feed amount and micro-adjustment, which is applied in the field of machining tools, can solve the problems of complex shape of parts, large center of gravity offset, and influence of boring accuracy, etc., to achieve simple shape of parts, small center of gravity offset, and good structural rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

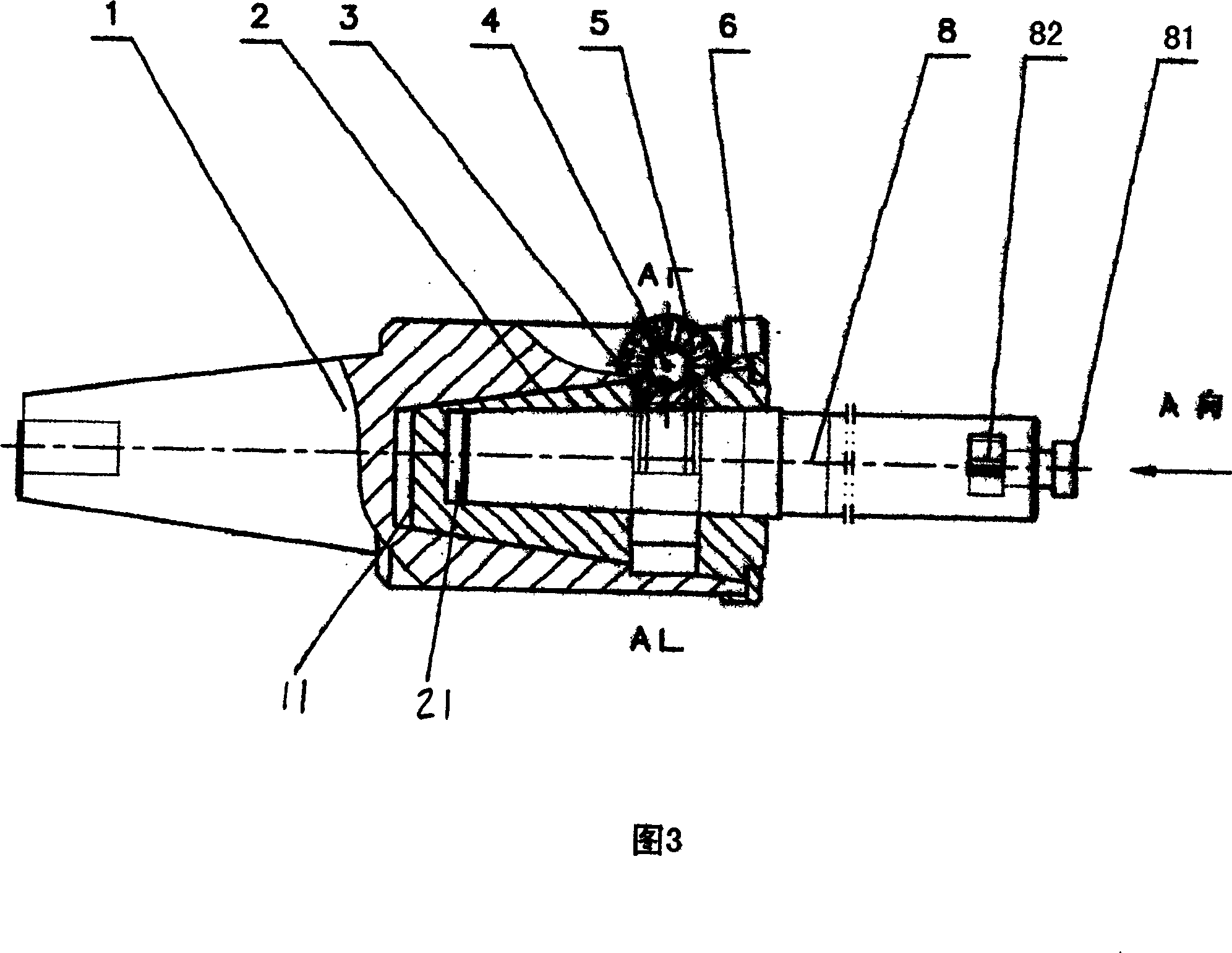

[0038] Referring to Fig. 3, Fig. 4 and Fig. 5, the fine-tuning device for the amount of tool feed in this embodiment is applied to a milling machine. The eccentric taper hole 11 of the body 1 axis. In the eccentric taper hole 11, the rotating cone 2 is installed through the end cap and the compression ring 6 which are threadedly connected with the handle body 1. On the rotating cone 2, there is also an eccentric taper hole 21 deviated from the axis of the rotating cone 2. In the eccentric taper hole 21 of the rotating cone 2 axis, a replaceable tool bar 8 is housed, and a cutter 82 is installed by a fastening screw 81 at the front end of the replaceable tool bar 8 .

[0039] A worm wheel 3 is installed on the rotating cone 2 , and of course the worm wheel 3 can also be directly processed on the outer surface of the rotating cone 2 . The worm 4 is installed on the handle body 1 through two bearing end caps 5 and meshes with the worm wheel 3 to drive the rotating cone 2 to rota...

Embodiment 2

[0044] Referring to Fig. 6-Fig. 9, the fine-tuning device for the feed amount of the tool in this embodiment is applied to a milling machine, and the taper shank of the tool handle body 1 is matched with the taper hole of the milling machine spindle.

[0045] The fine-tuning accuracy can be designed according to the principle. In this embodiment, the worm 4 is designed to make one revolution, and the diameter is reduced by 0.5 millimeters. The rotation and diameter reduction indicator dial 7 on the worm 4 has 50 scale lines, indicating that each grid has a diameter reduction of 0.01 millimeters.

[0046] In this embodiment, in the eccentric taper hole 11 of the handle body 1 , the rotating cone 2 with the taper hole 22 is installed through the pressure spring ring 6 and the anti-loosening cover 61 threadedly connected with the handle body 1 . The axis of the tapered hole 22 coincides with the axis of the rotating cone 2 .

[0047] The incomplete worm wheel 31 in the worm and g...

Embodiment 3

[0055] Embodiment 3 is applied to a machining center machine tool, as shown in Figure 10. The difference from Embodiment 2 is: 1. The taper shank of the tool handle body 1 cooperates with the taper hole of the machining center spindle; There are two forms of rotary reducer.

[0056] Cutter 82 and replaceable cutter bar 8 adopt screw drive, and a straight line moving variable-diameter indicator dial 84 is arranged on the drive screw rod, and indicating line is engraved on the replaceable cutter bar 8.

[0057] Between cutter 82 and replaceable cutter bar 8 can adopt oblique line or linear movement variable diameter, the included angle between the axis of cutter 82 and the axis of replaceable cutter bar 8 is blind hole or through hole design according to processing object.

[0058] Rotary variable diameter is adopted on the tool handle body 1, and the fine-tuning accuracy can be designed according to the above-mentioned principle. In this embodiment, the worm 4 rotates once to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com