Dyeing assistants for soybean fiber, and dyeing technique

A technology of soybean protein fiber and dyeing auxiliaries, applied in the field of textile dyeing and finishing, can solve the problems of rough hand feeling of textiles, scratches of dyed textiles, affecting the grade and selling price of dyed textiles, etc., so as to improve the dyeing effect and dyeing quality. , reduce environmental hazards, high-grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the dyeing of soybean protein fiber fabric

[0030] 1. Dyeing fabric: plain weave, warp density: 246 / 10cm, weft density: 173 / cm, yarn linear density: 14.5tex×2

[0031] 2. The dyeing equipment is Rotawinch winch rope dyeing machine

[0032] 3. Dye: Cibacron LS series reactive dyes for cotton

[0033] 4. The dyeing bath formula is shown in Table 1, and the dyeing bath ratio is 15:1

[0034] Table 1: Dyebath composition for dyeing by different processes

[0035]

[0036] 5. The composition of the soap bath is shown in Table 2:

[0037]

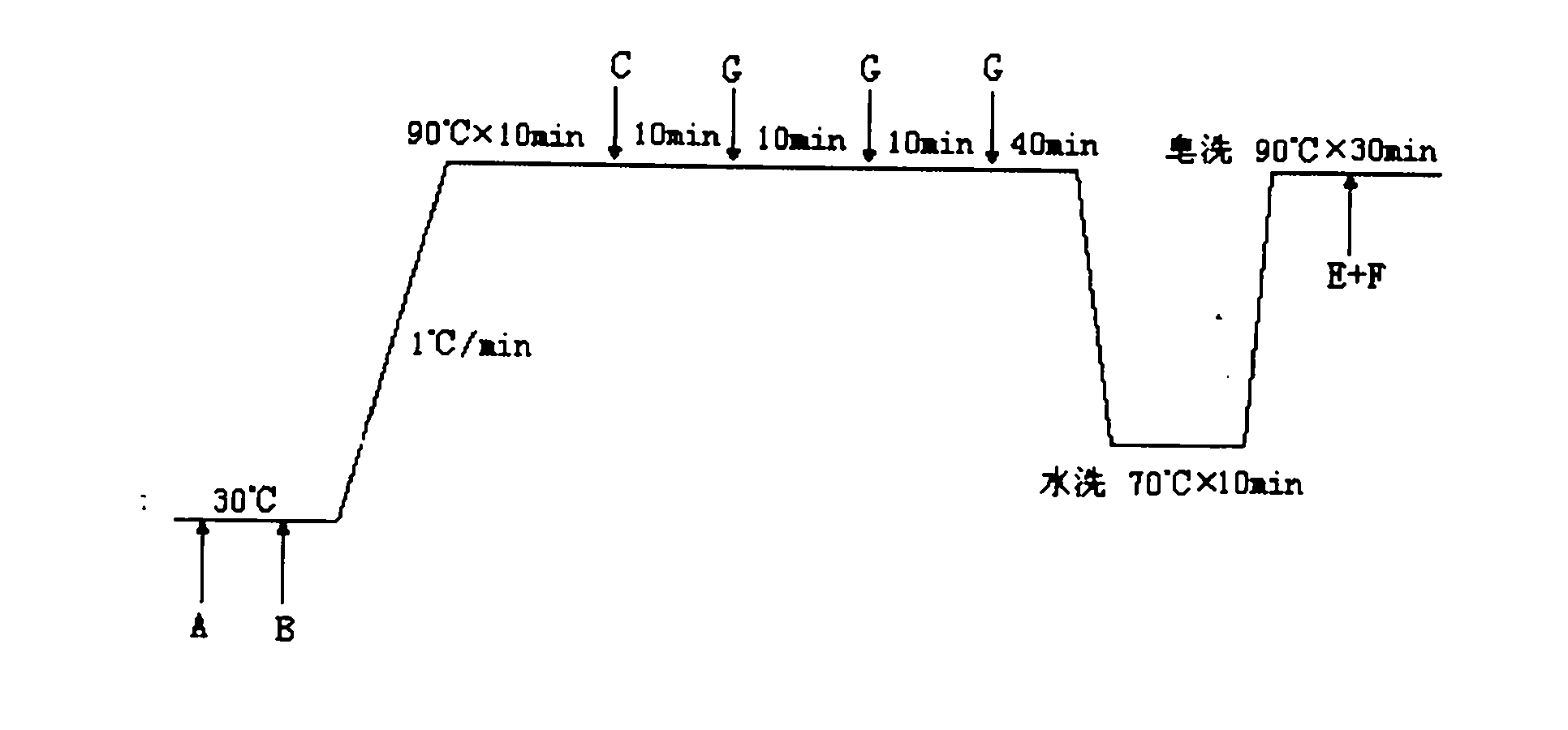

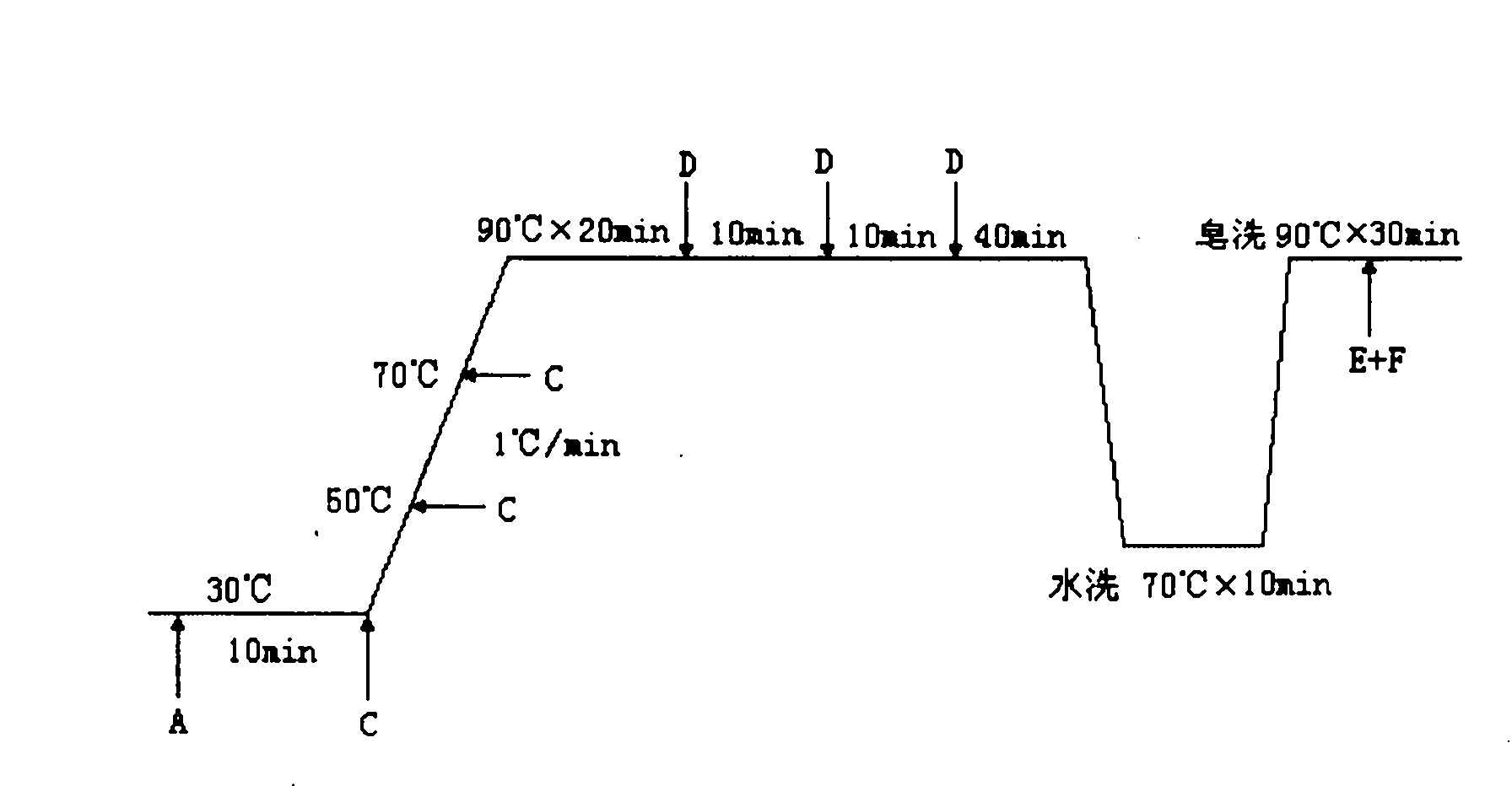

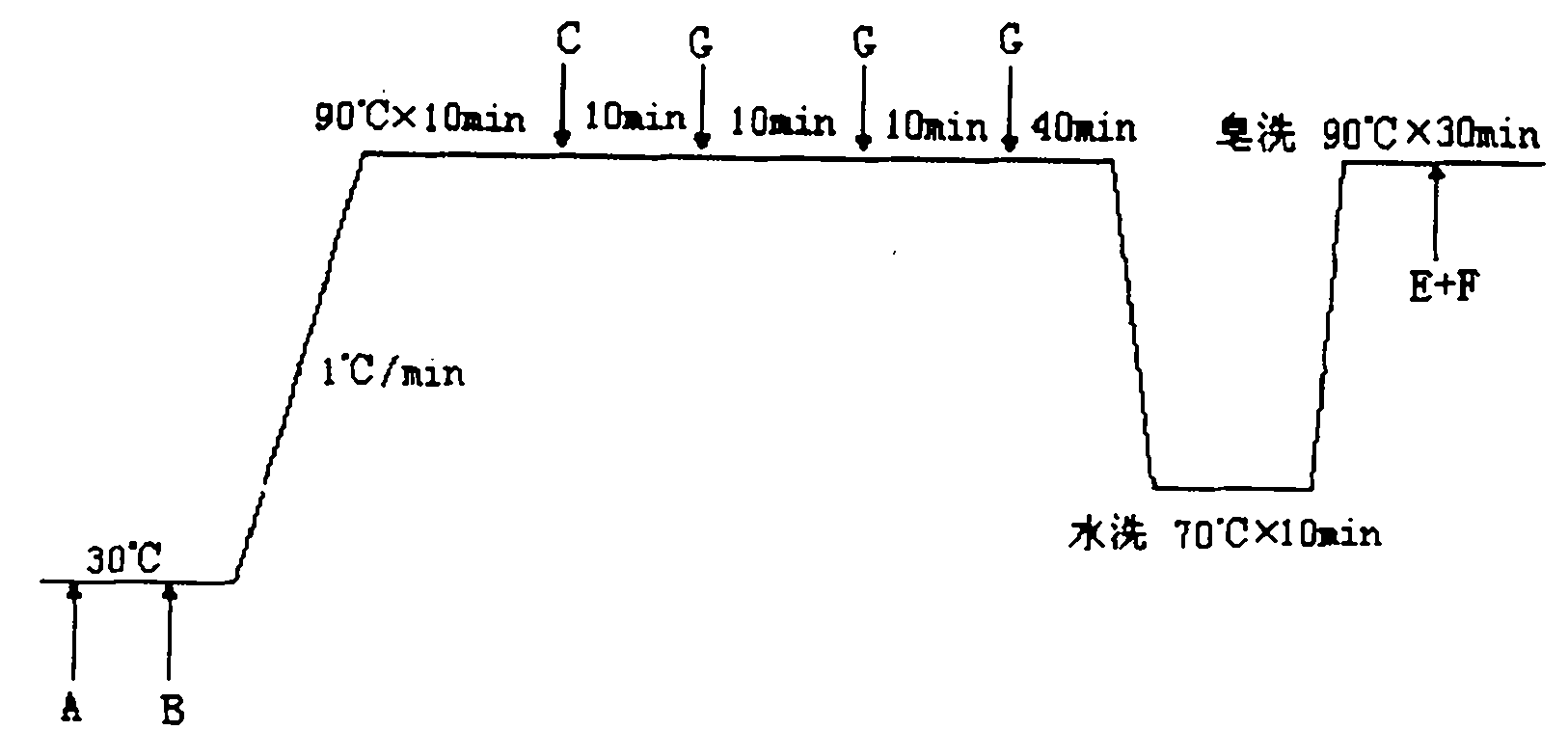

[0038] 6. The process curve of traditional dyeing is figure 2 , the process curve of dyeing by the process of the present invention is figure 1 .

[0039] 7. The dyeing depth of dyed samples obtained by dyeing with different processes is expressed by K / S value, and the specific data are given in Table 3.

[0040] Table 3: K / S values of fabrics dyed by different processes

[0041]

Embodiment 2

[0042] Embodiment 2: Dyeing of soybean protein bulk fiber

[0043] 1. Dyeing fiber: 1.1-1.2(dtex)×38mm.

[0044] 2. Dyeing equipment: ALLWIN loose fiber dyeing machine

[0045] 3. Dye: Cibacron LS series reactive dyes for cotton

[0046] 4. The composition of the dye bath is the same as in Table 1, and the dye bath ratio is 10:1.

[0047] 5. The composition of the soap bath is the same as in Table 2.

[0048] 6. The process curve of traditional dyeing is figure 2 , the process curve of dyeing by the process of the present invention is figure 1 .

[0049] 7. The color depth comparison of dyed samples obtained by different processes is similar to that of fabric dyeing.

Embodiment 3

[0050] Embodiment 3: the dyeing of soybean protein fiber top

[0051] 1. Dyeing top: 20g / m

[0052] 2. Dyeing equipment: ALLWIN cheese dyeing machine

[0053] 3. Dye: Cibacron LS series reactive dyes for cotton

[0054] 4. The composition of the dye bath is the same as in Table 1, and the dye bath ratio is 10:1.

[0055] 5. The composition of the soap bath is the same as in Table 2.

[0056] 6. The process curve of traditional dyeing is figure 2 , the process curve of dyeing by the process of the present invention is figure 1 .

[0057] 7. The color depth comparison of dyed samples obtained by different processes is similar to that of fabric dyeing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com