High-pressure and ultra-high pressure injection pump plunger with annular groove

An ultra-high pressure, fuel injection pump technology, applied in the field of auto parts, can solve the problems of limited manufacturing and matching precision, sluggish plunger movement, jamming, etc., to reduce fuel leakage rate, reliable injection pressure, and prevent plunger jamming dead effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

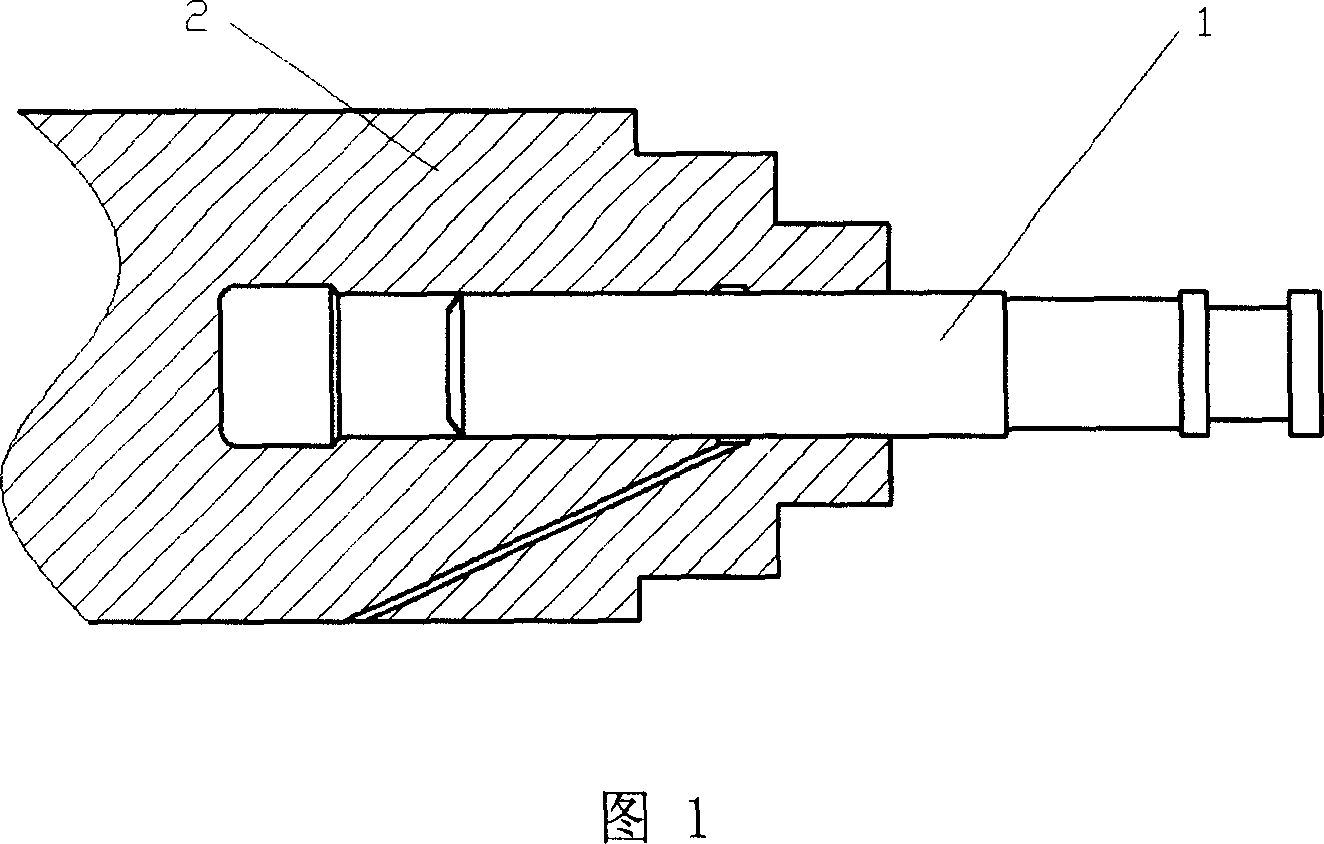

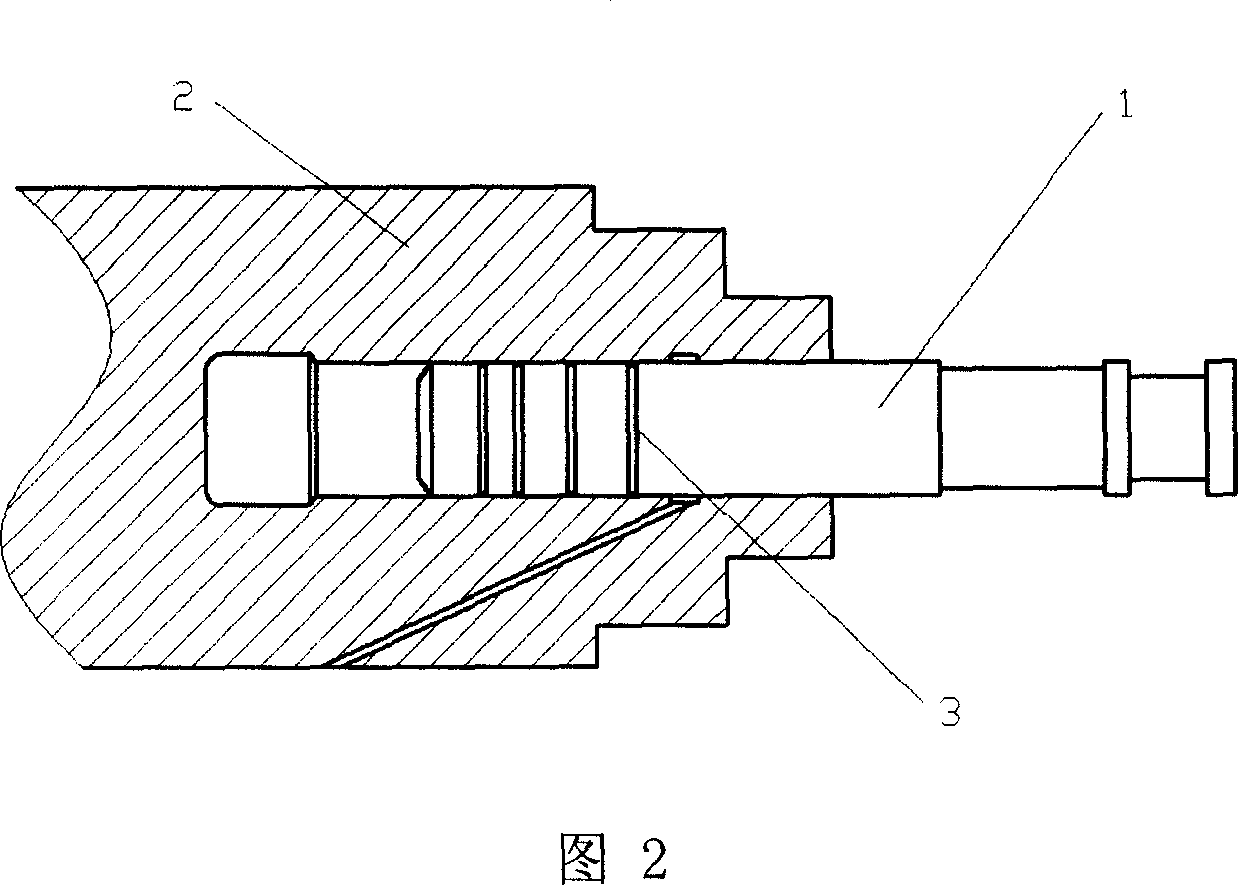

[0012] The invention proposes a high-pressure and super-high-pressure fuel injection pump plunger with an annular groove. In the schematic diagram of the plunger structure of the high-pressure and ultra-high-pressure pump shown in Figure 2, the cylindrical mating surface of the high-pressure and ultra-high-pressure pump plunger 1 in the pump body 2 has a semicircular, rectangular, trapezoidal or triangular cross-sectional shape. ring groove 3. The number n of grooves 3 depends on factors such as fit clearance, machining accuracy, plunger diameter, stroke, and injection pressure. Depending on the factors, for example, when the diameter of the plunger is 14mm, it can take 1-6mm. The annular groove 3 on the cylindrical mating surface of the plunger is arranged in n channels according to factors such as the plunger diameter, stroke and injection pressure, which can greatly reduce the fuel leakage rate and reduce the plunger pressure under the same fitting clearance and sealing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com