Cathode piece of hydrogen-nickel battery, and method for fabricating hydrogen-nickel battery by using the cathode pieces

A technology of nickel-hydrogen battery and manufacturing method, which is applied in the manufacture of alkaline storage batteries, battery electrodes, nickel storage batteries, etc., which can solve problems such as low utilization rate, excess capacity of active materials, and excess capacity of active materials at the tail of the negative electrode, so as to avoid breakage , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

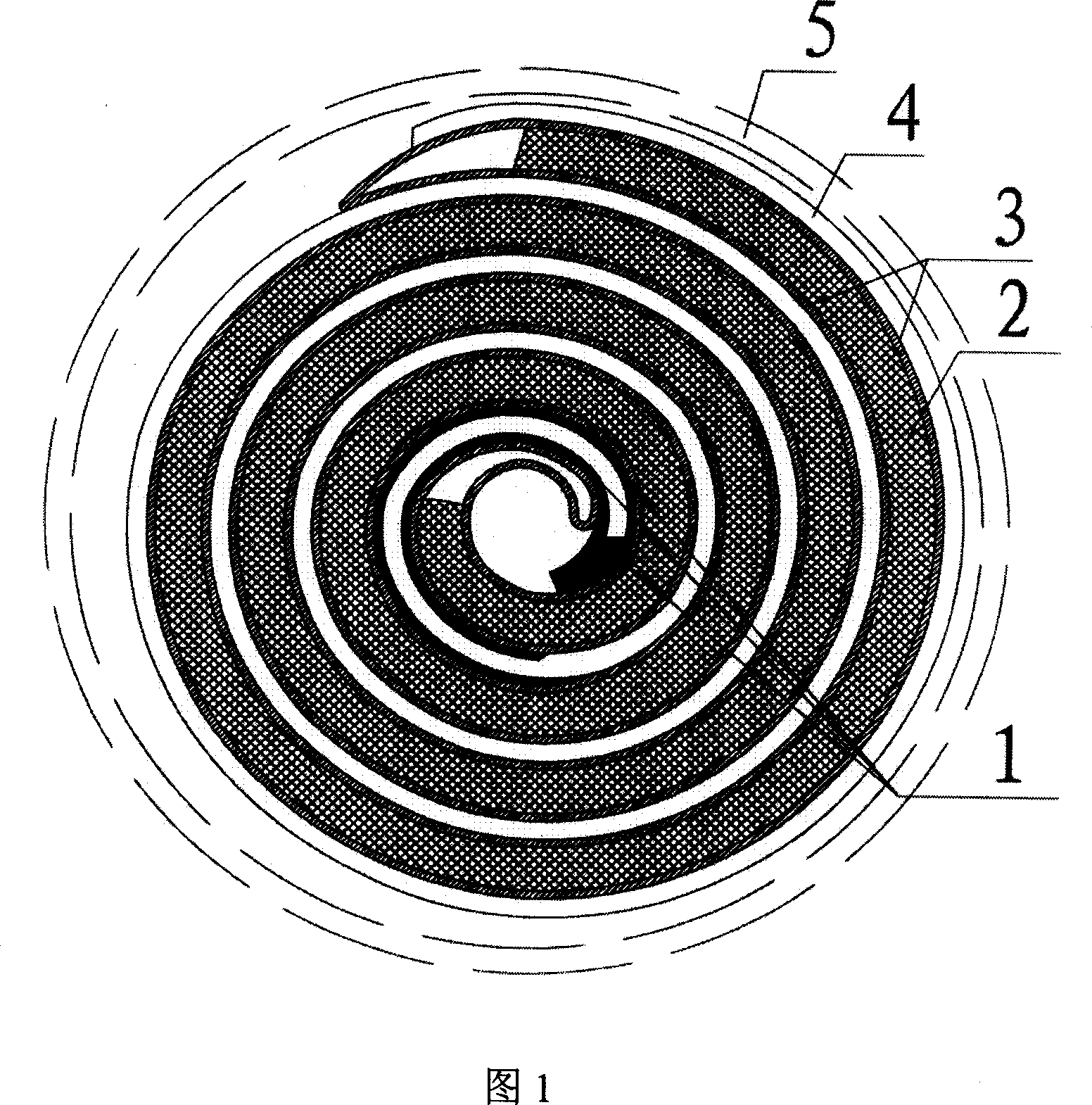

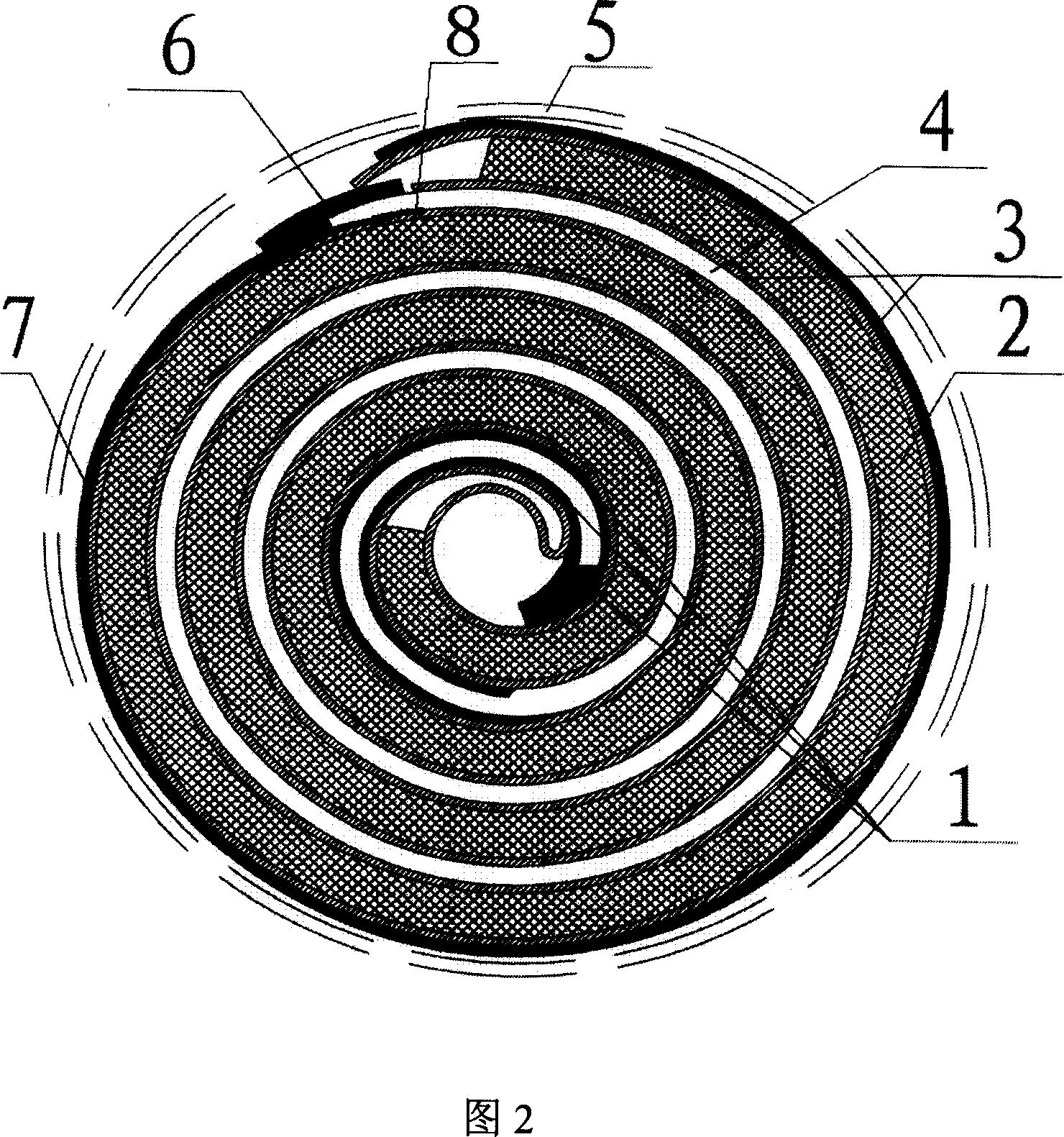

[0034] An AA-type nickel hydrogen battery with a capacity of 2400mAh. The negative electrode sheet is a double negative electrode sheet including a single long negative electrode sheet 4 and a single negative electrode short sheet 7. The end of the single long negative electrode sheet 4 is connected to the substrate through a pure nickel tape negative electrode 6 Welded monolithic negative short piece 7 composition.

[0035] This method for manufacturing a nickel-hydrogen battery with double negative electrodes includes the steps of manufacturing positive and negative electrodes, assembling batteries, and forming batteries in sequence. The manufacturing of the negative electrode sheet is to first pass the nickel-plated steel mesh negative electrode substrate through the powder box containing the rare earth hydrogen storage alloy powder, so that the rare earth hydrogen storage alloy powder is embedded in the mesh and both sides of the nickel-plated steel mesh negative electrode sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com