A method for measuring liquid phase micro-area temperature

A liquid phase, temperature measuring probe technology, applied in the application of thermometers, thermometers, measuring devices, etc., can solve the problems of inability to use spatial scale measurement, low spatial resolution of temperature measurement, affecting temperature measurement objects, etc., and achieve high temperature measurement. , high spatial resolution, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, optical tweezers are used as the micromechanical control means to accurately position the temperature measuring probe, and the temperature of a certain micro-region of water and ethanol aqueous solution is measured at different temperatures.

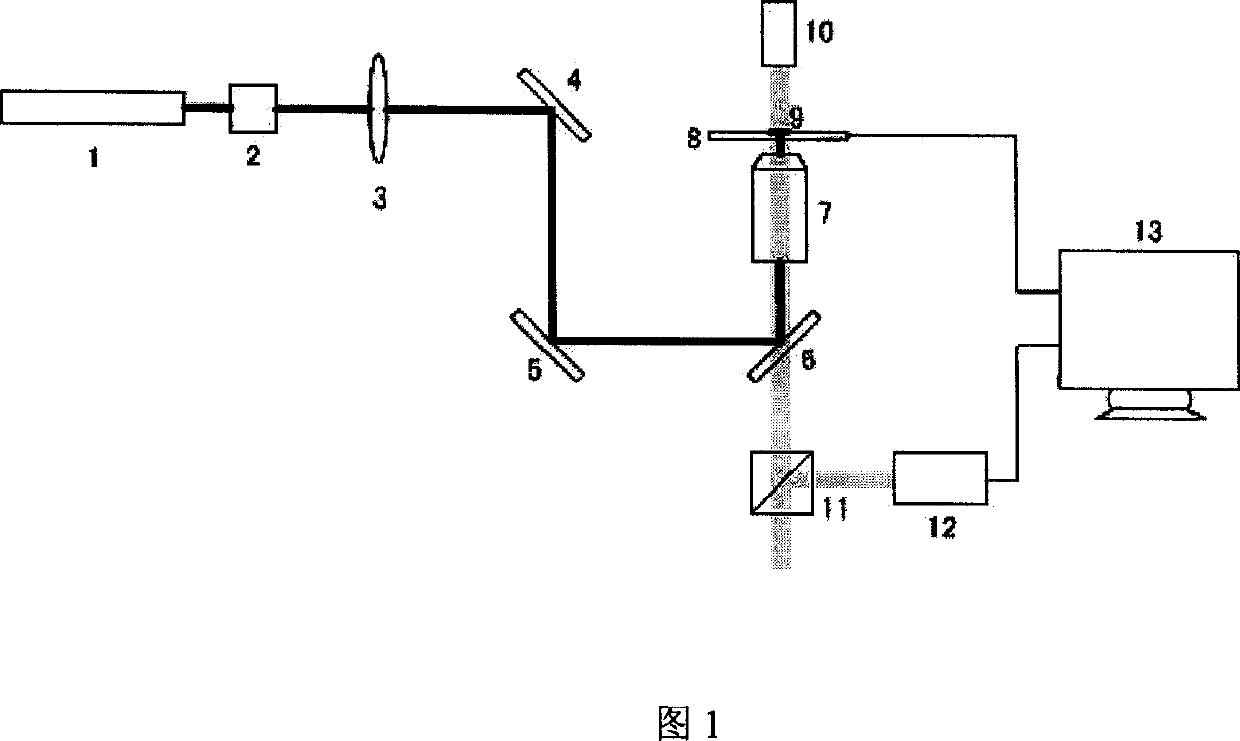

[0020] Fig. 1 has provided a kind of nano-optical tweezers system device that present embodiment adopts, and it is made of laser 1, microscope (main components have dichromatic reflector 6, 100 times of oil immersion objective lens 7, halogen illuminator 10, beam splitting prism 11 ), a piezoelectric scanning platform 8, a digital camera 12, a computer control system 13 and mirrors and other optical components: a helium-neon (He-Ne) laser 1 with a power of 10 mW and a wavelength of 632.8 nm is used as the optical tweezers light source, and the output After the laser beam is expanded by beam expander 2 and collimated and focused by collimator lens 3, it is reflected by mirror 4 and mirror 5, coupled into the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com