Testing apparatus for high temperature, superconducting, magnetic suspension and dynamic performance and testing method with the same

A high-temperature superconducting and testing device technology, which is applied in the direction of measuring devices, motor generator testing, and electric/magnetic devices to transmit sensing components, can solve problems such as the inability to simulate the operation of high-temperature superconducting maglev vehicles, and achieve convenient and automatic Effects of control and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

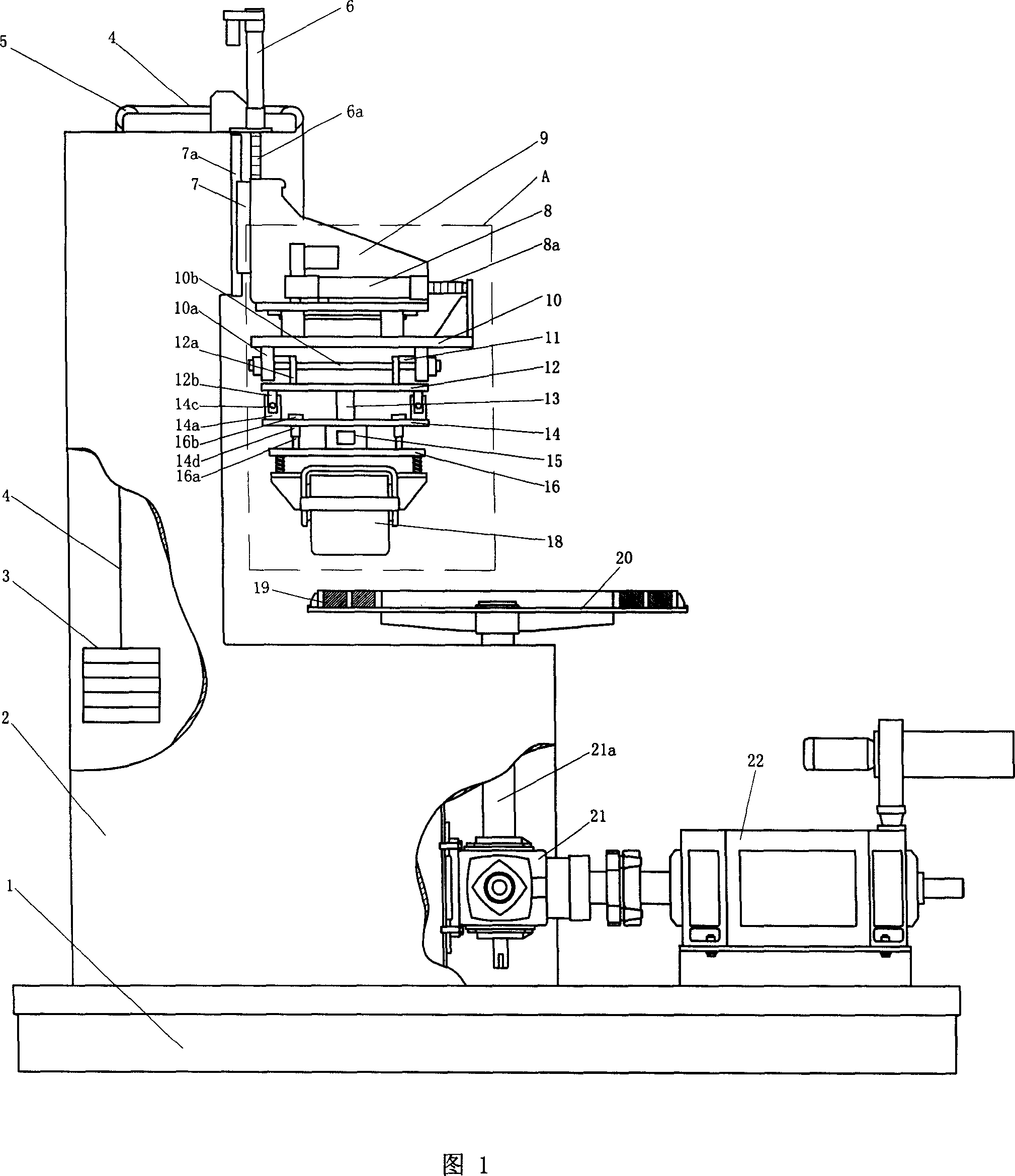

[0087] Fig. 1 shows a kind of high-temperature superconducting magnetic levitation dynamic performance testing device of the present invention, and it consists of:

[0088] a, the anti-seismic base 1 is equipped with a stainless steel L-shaped frame 2 and a horizontal stainless steel disc 20 driven by a motor 22, and a circle of high-temperature ultra- Guide car with magnetic track 19.

[0089] b. A vertical loading electric cylinder 6 is installed on the top of the L-shaped frame 2, and the screw rod 6a below the vertical loading electric cylinder 6 is connected to the support frame 9 of the three-dimensional force measuring device A, and the back of the support frame 9 slides vertically Installed on the inner side of the upper part of the L-shaped frame 2; the support frame 9 is fixed with a laterally loaded electric cylinder 8, and the screw rod 8a protruding forward of the electric cylinder 8 is connected with the side plate of the upper slide plate 10, and the upper slide...

Embodiment 2

[0105] The composition of this example is basically the same as that of Embodiment 1, and the difference is only: the output shaft 21a of the transmission mechanism 21, which is connected to the center of the vertical stainless steel disc 20, and the annular high-temperature superconducting vehicle magnetic rail 19 is fixed Above the edge of the stainless steel disc 20, the arrangement of multiple high-temperature superconducting blocks in the Dewar vessel 18 is arc-shaped, and the center of the arc is the same as the center of the high-temperature superconducting vehicle magnetic rail 19, that is, the stainless steel circle. The center of the disc coincides.

Embodiment 3

[0107] The composition of this example is basically the same as that of Embodiment Two, except that the vertical stainless steel disk 20 is two coaxially connected; Above the edge, so that two sets of high-temperature superconducting blocks side by side can be tested, and the magnetic levitation performance under the condition of relative motion with a pair of high-temperature superconducting vehicle magnetic rails 19 can be more realistically simulated on both sides of the high-temperature superconducting maglev train The test data of the superconducting bulk material and the state running above the two rails are more practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com