Cleaning device for cleaning welding torches

A technology for cleaning devices and welding torches, applied in auxiliary devices, welding accessories, welding equipment, etc., can solve problems such as failure of other equipment or control systems, and achieve the effects of reducing cleaning time, reducing costs, and increasing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

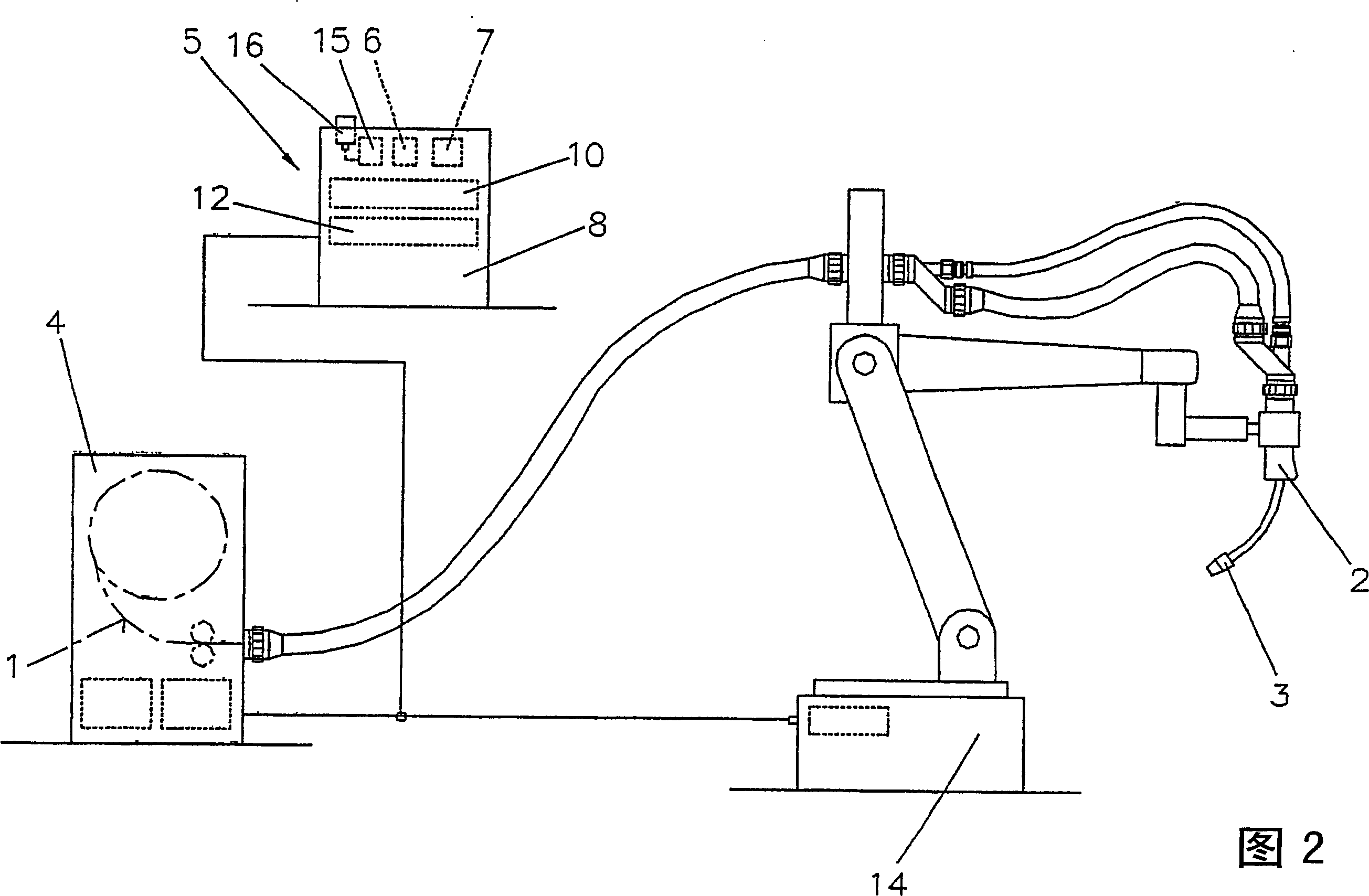

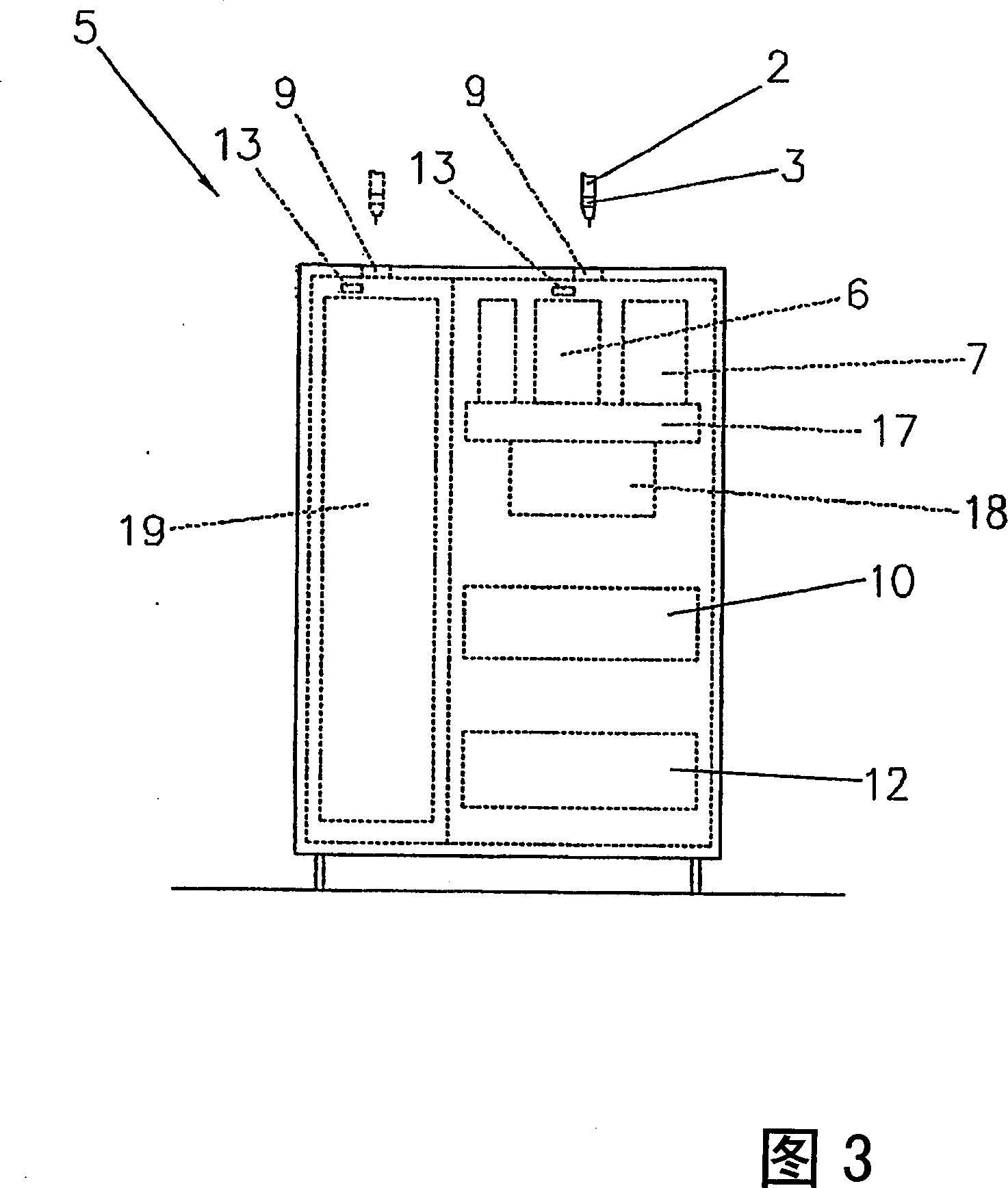

[0015] Because different welding materials and welding electrodes 1 are often used in welding technology, resulting in different welding slags adhering to the welding gun 2, especially on or in the gas nozzle 3, or due to the application of welding with different welding materials. Unit or welding device 4, it is often necessary to clean welding torch 2 using different cleaning methods. For this purpose, the different cleaning devices 6 , 7 according to the invention for cleaning the welding torch 2 are arranged in the cleaning device 5 or cleaning device and can thus be selected automatically or by the user.

[0016] In the prior art, as a rule, only a single device 6 or 7 is constructed as a stand-alone device, so that in many cases different devices have to be used for optimal cleaning of the welding torch 2 . The disadvantage is that each individual device must be properly installed and cabled, and space needs to be increased at the same time.

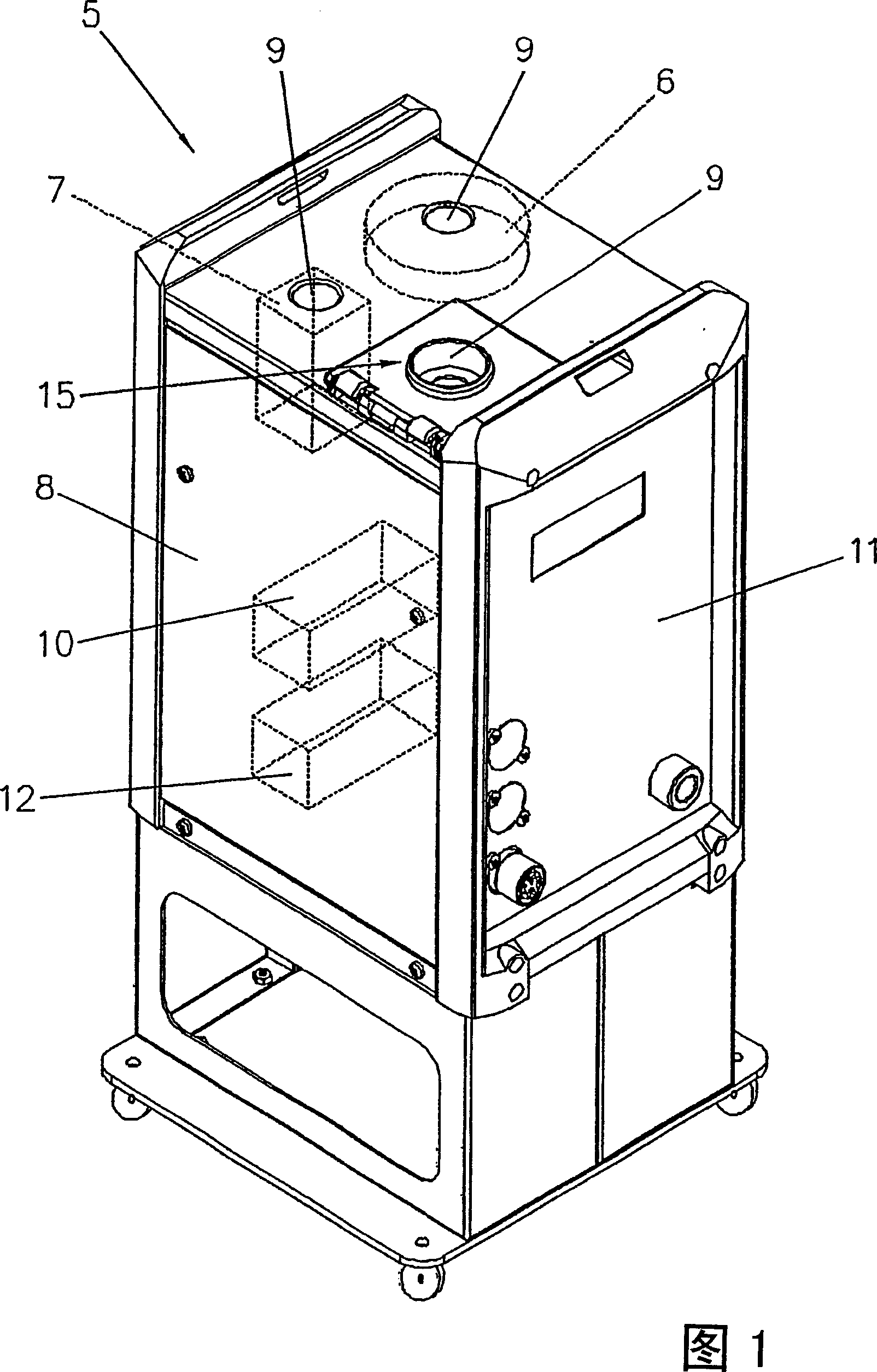

[0017] FIG. 1 is a perspec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com