Linear knitting machine

A knitting machine, horizontal type technology, applied in knitting, warp knitting, flat warp knitting machines, etc., can solve the problems of unfavorable manufacturing cost, permanent deformation, unfavorable final operating speed of the machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

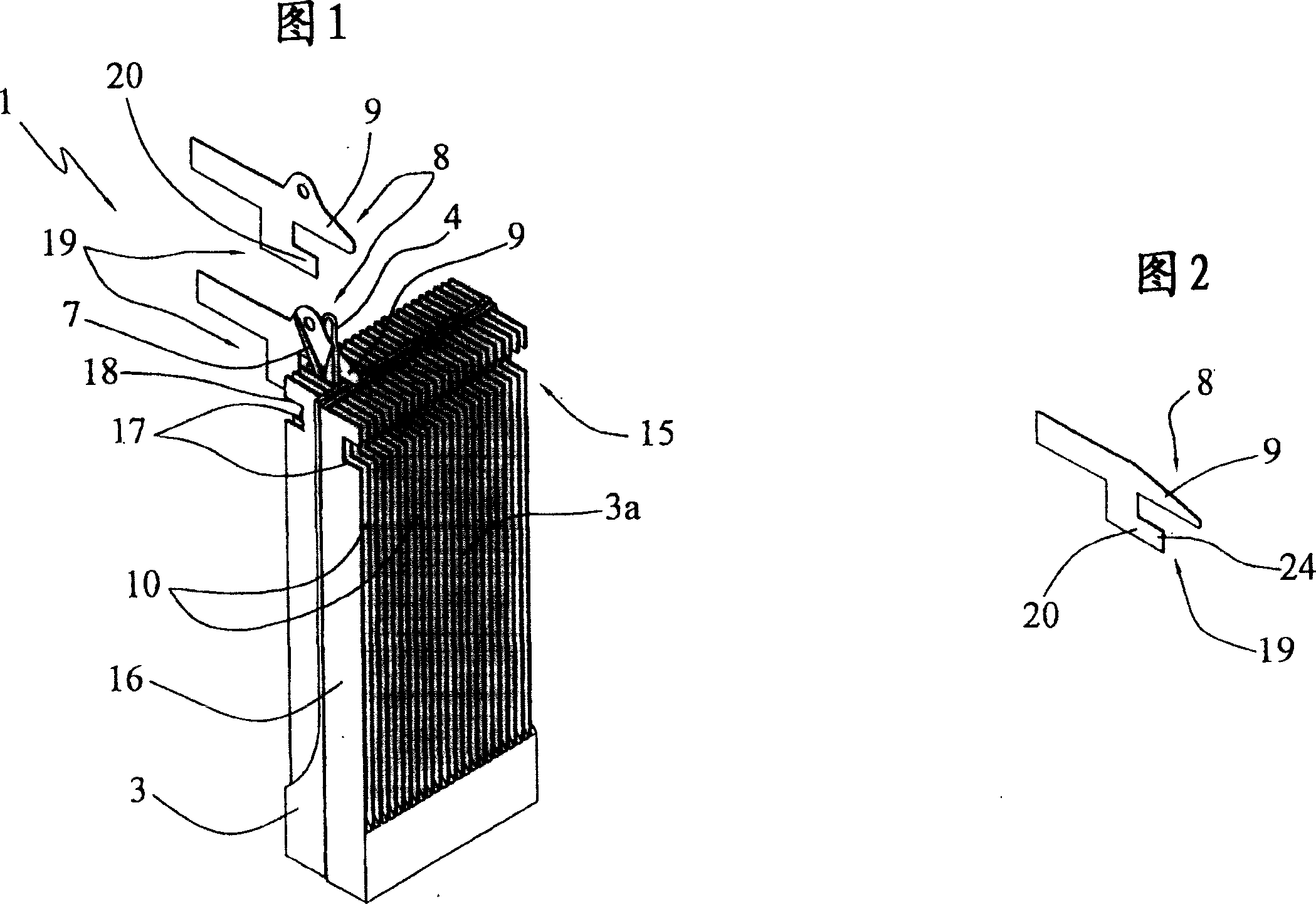

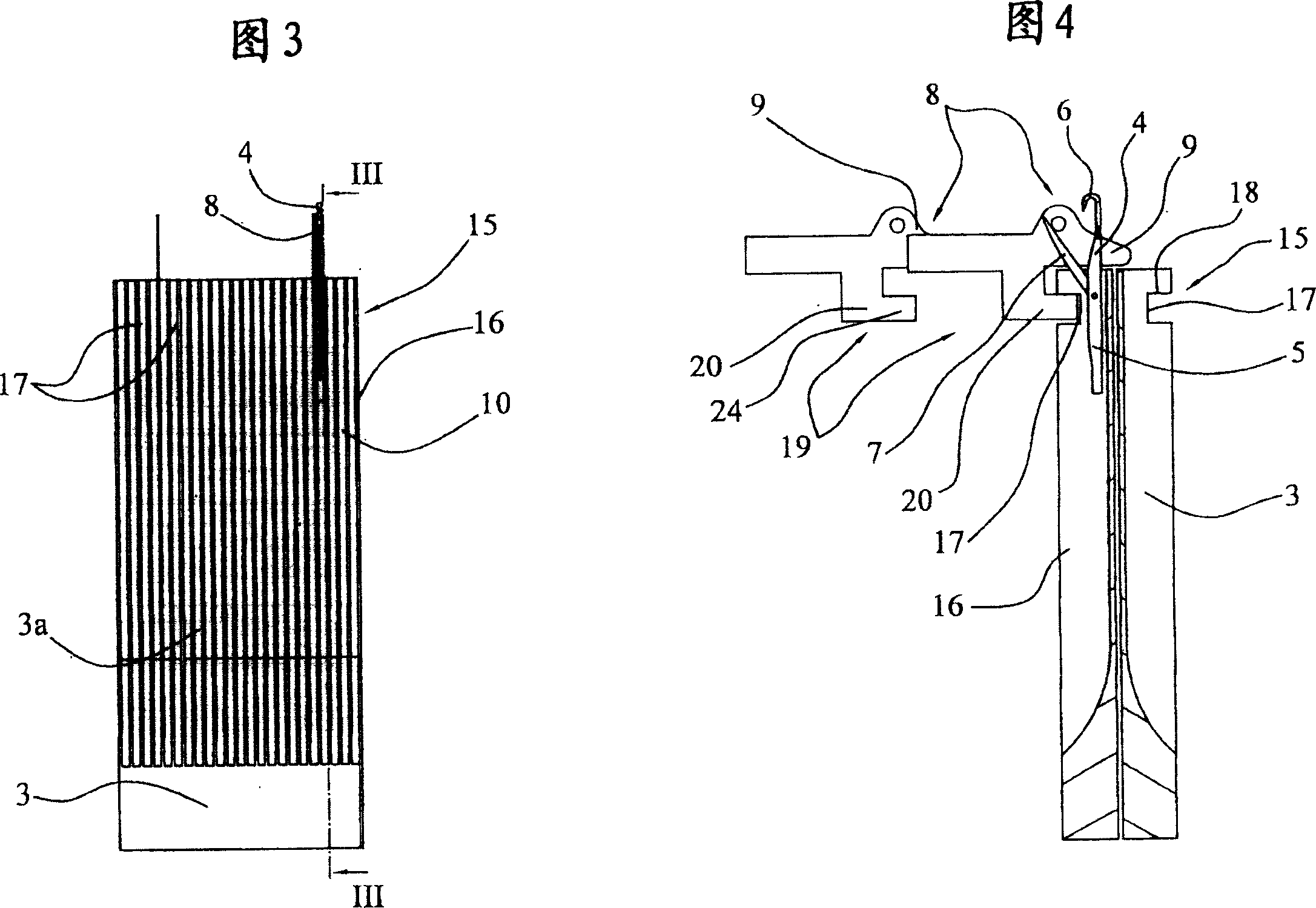

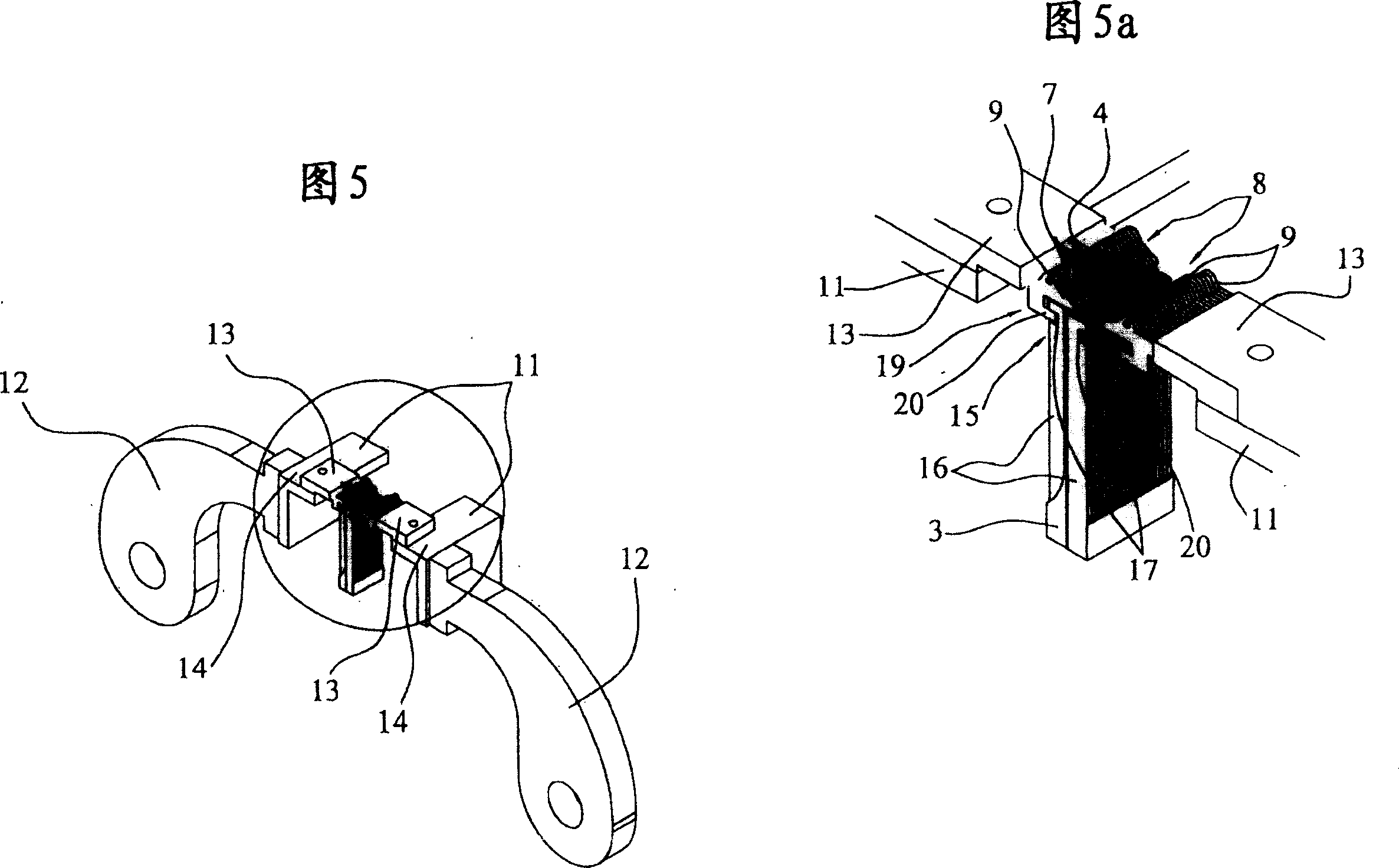

[0028] With reference to the above-mentioned figures, the horizontal knitting machine 1 according to the present invention comprises a frame, at least one needle bed 3 associated with said frame, a plurality of needles 4 sliding in the needle bed 3 and the The gripping device 8 that knitting needle 4 cooperates. Said means 8 can be moved between a front position which is assumed when the needles 4 are raised in the needle bed 3 and in which position the gripping means 8 act on the loops to hold them in said knitting position, and a rear position. On the needle shaft 5 of the needle 4, the rear position is present when the knitting needle 4 is lowered and in this position the holding device 8 does not act on the loop, as can be seen from FIG. In the embodiment of the machine the coil is located between the holding device 8 and the needle bed 3).

[0029] The horizontal knitting machine according to the invention is characterized in that it also comprises clamping means 15 fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com