Binding-packaging process for triple purifier of automobile

A packaging process and purifier technology, which is applied to mufflers, exhaust devices, engine components, etc., can solve problems such as stress concentration, high compression density of expansion pads, packaging quality accidents, etc., and achieve uniform stress concentration and dispersion, and stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

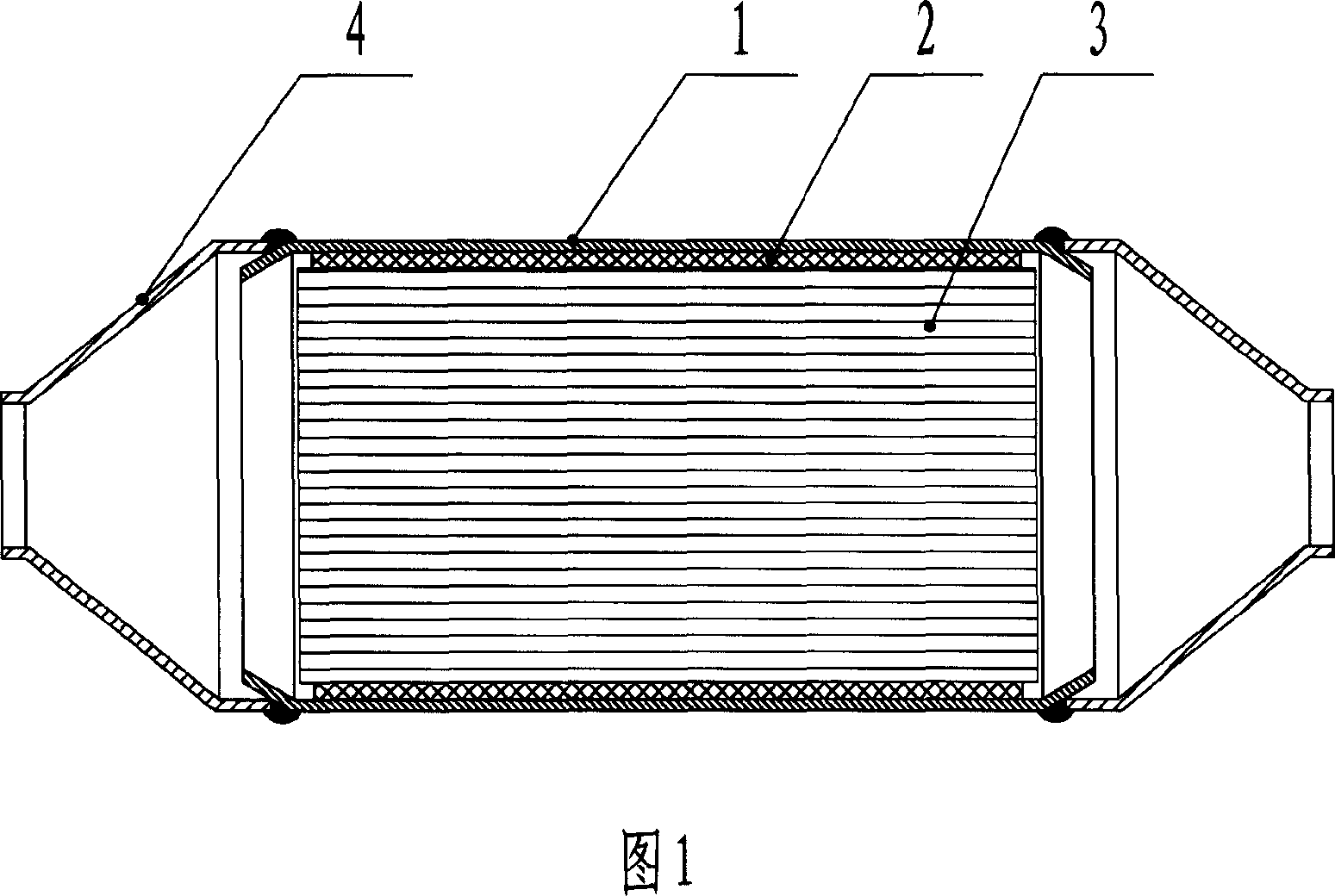

[0014] As shown in Figure 1, a three-way purifier for automobiles comprises a catalytic converter housing 1, and a carrier 3 is wrapped and plugged in the catalytic converter housing 1 with an expansion gasket 2, and cones 4 are welded at both ends of the catalytic converter housing 1, and the catalytic converter Both ends of the casing 1 are narrowed.

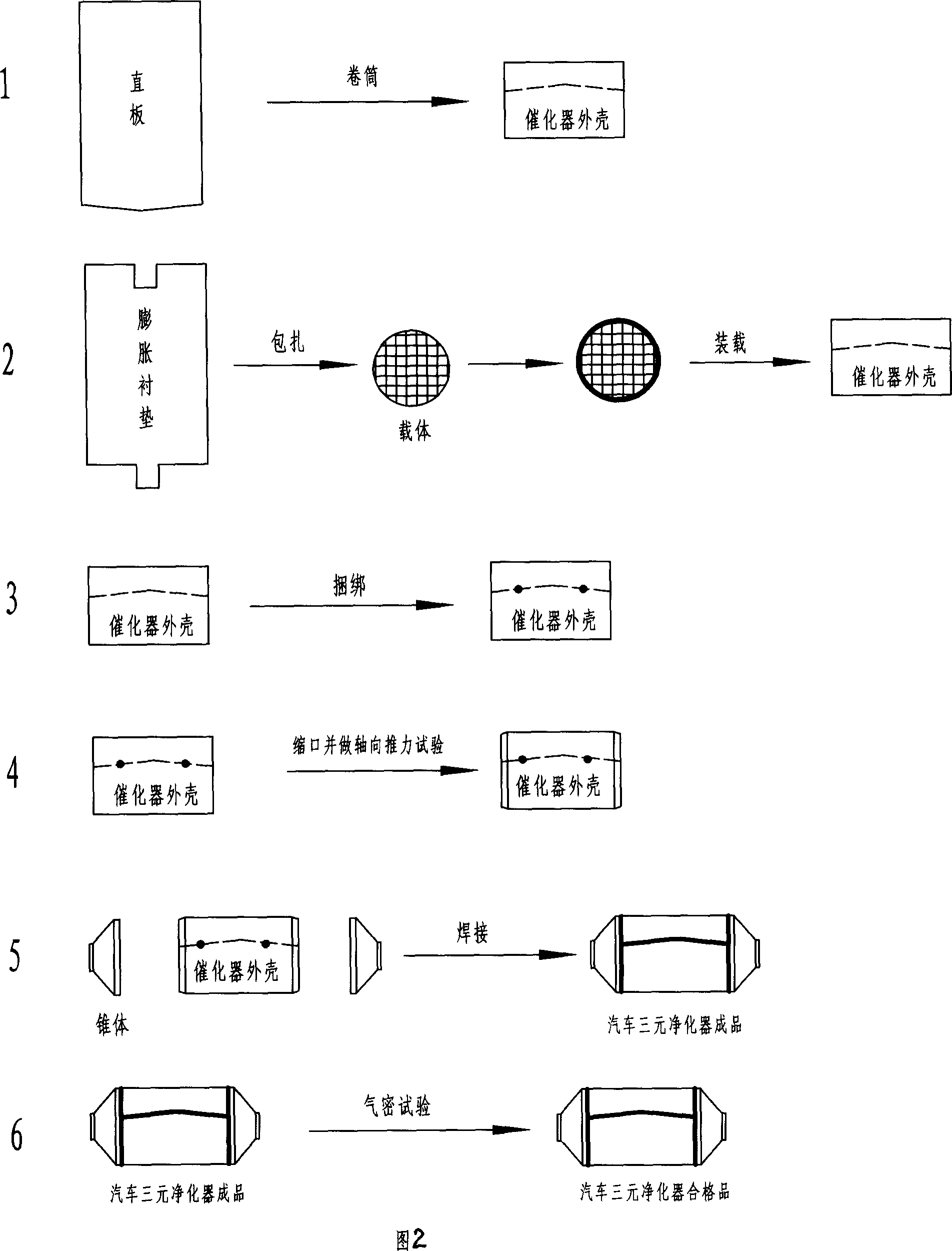

[0015] As shown in Figure 2, a bundled packaging process for an automotive ternary purifier, the process steps are as follows:

[0016] 1), reel: roll the straight plate into the catalytic converter shell;

[0017] 2) Loading: wrap the carrier with an expansion liner and put it into the catalytic converter shell;

[0018] 3) Binding: Tighten the catalytic converter housing with the liner and carrier installed under the action of the binding belt, and then perform high-frequency vibration to make the force generated by the binding evenly distributed, and fix the interface of the catalytic converter housing by spot welding;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com