Volume-variable bi-directional rotary pump and hydraulic loop using the pump

A two-way rotation and capacity technology, applied in the direction of liquid variable capacity machinery, pumps, pump control, etc., can solve the problems of large load torque, low load torque, and large-scale efficiency of the overall device, so as to reduce load torque and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

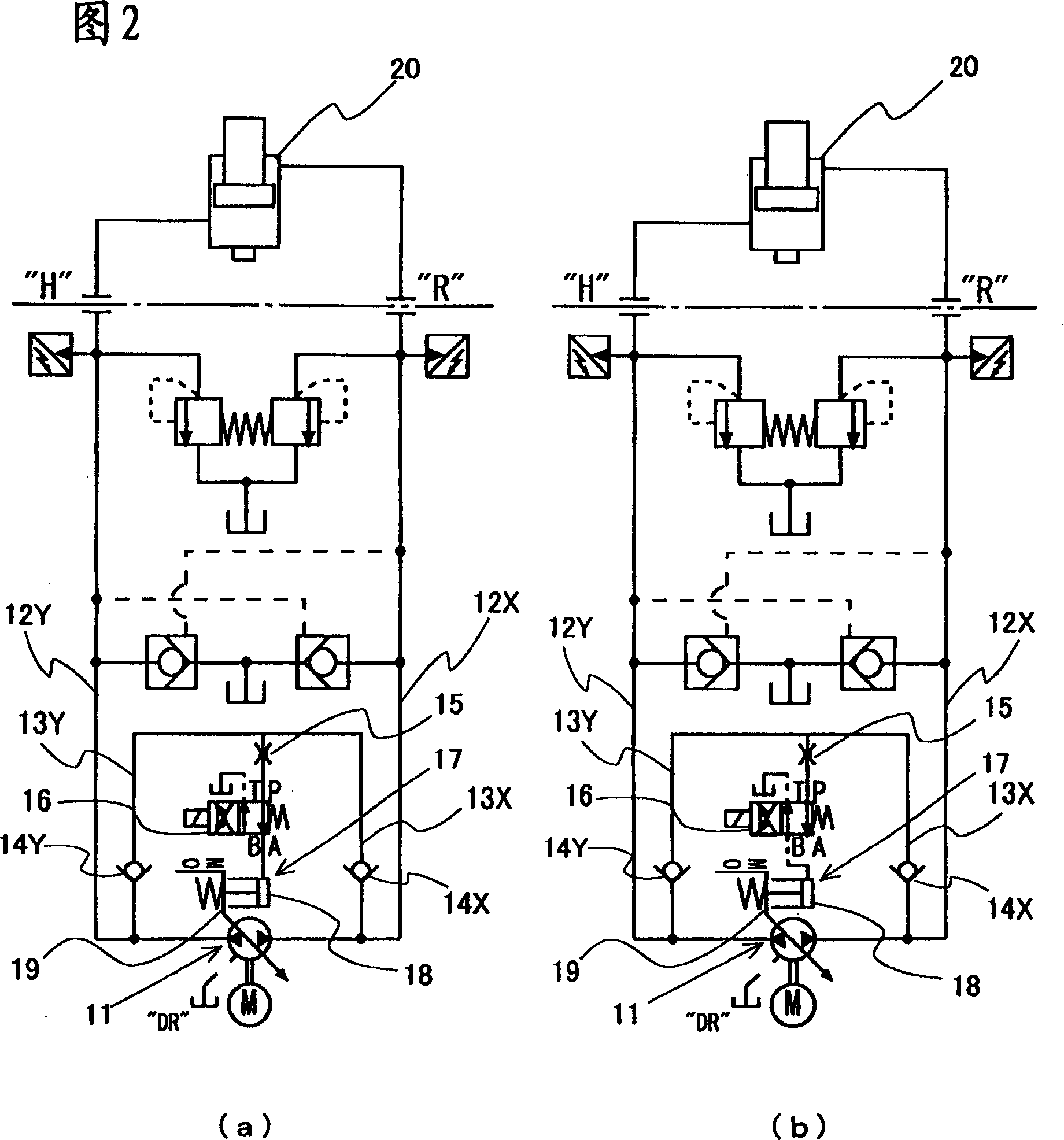

[0030] As an embodiment of the present invention, Fig. 2 shows a hydraulic circuit using a bidirectional rotary pump with a swash plate type variable capacity device. Fig. 2 (a) is a hydraulic circuit diagram showing the connection state of the second circuit for displacing the capacity variable mechanism to the small capacity side, and (b) is a hydraulic circuit diagram showing the formation of the second circuit for displacing the capacity variable mechanism to the large capacity side The hydraulic circuit diagram of the state of the primary circuit connection.

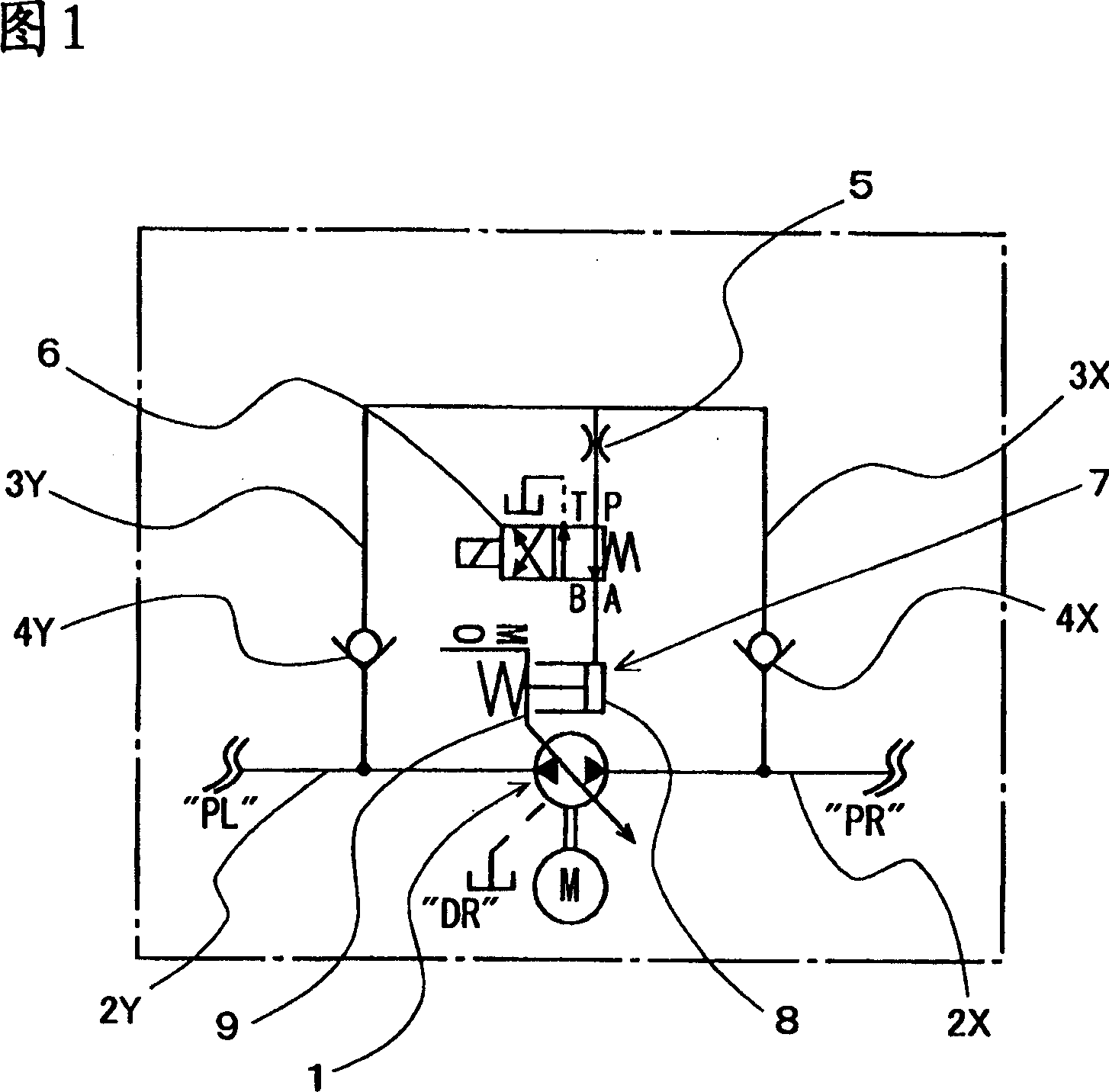

[0031] The hydraulic circuit of this embodiment represents a hydraulic control circuit formed by connecting two discharge ports of a variable capacity bidirectional rotary pump having the same structure as that shown in FIG. 1 in series with a hydraulic cylinder. That is, in the present variable capacity bidirectional rotary pump, the capacity variable mechanism 17 is provided on the bidirectional rotary pump mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com