Heat radiator

A heat dissipation device and heat technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the problems of condensation and lifespan not being well guaranteed, so as to save electric energy and improve service life , to avoid the effect of condensation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

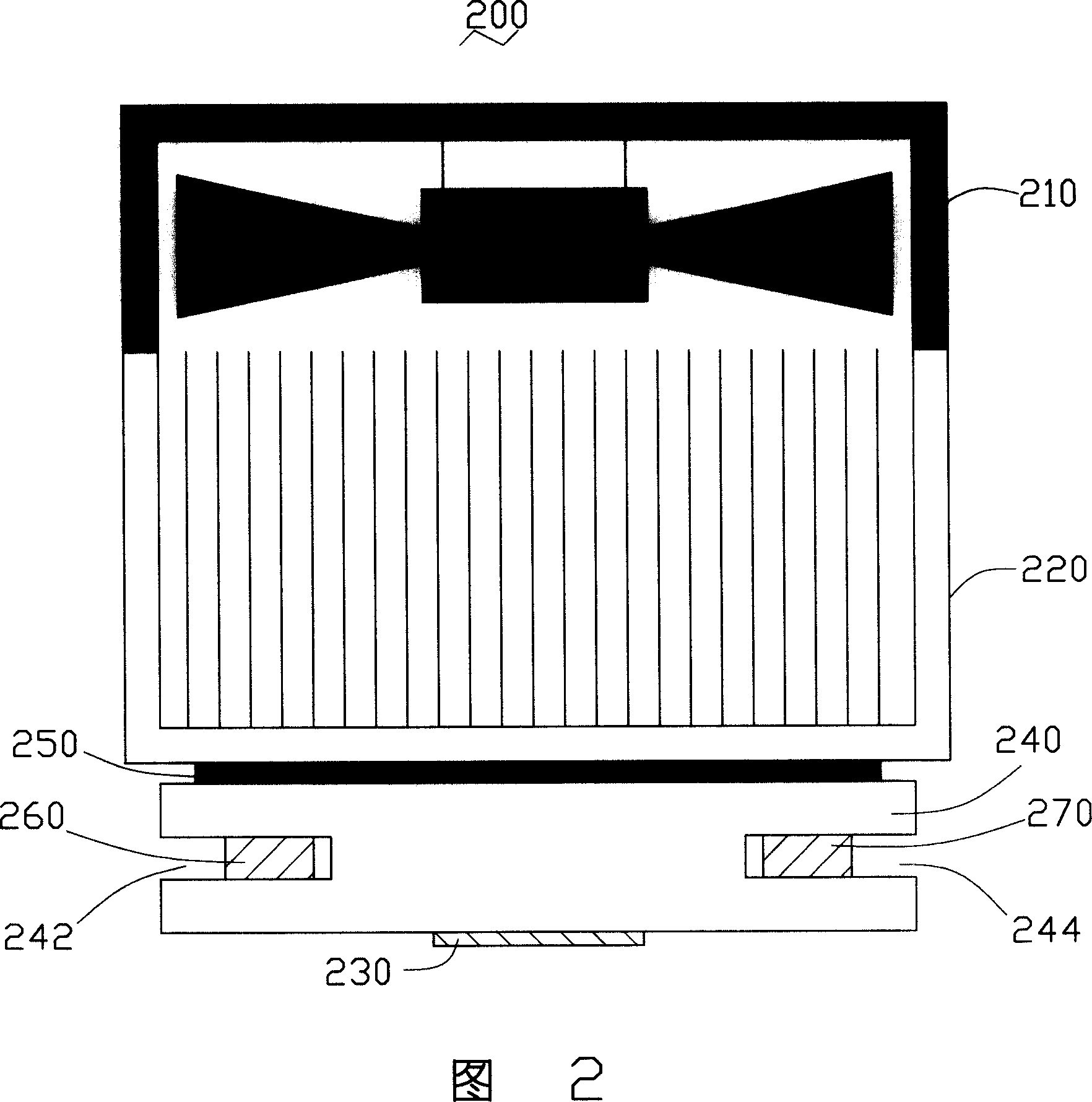

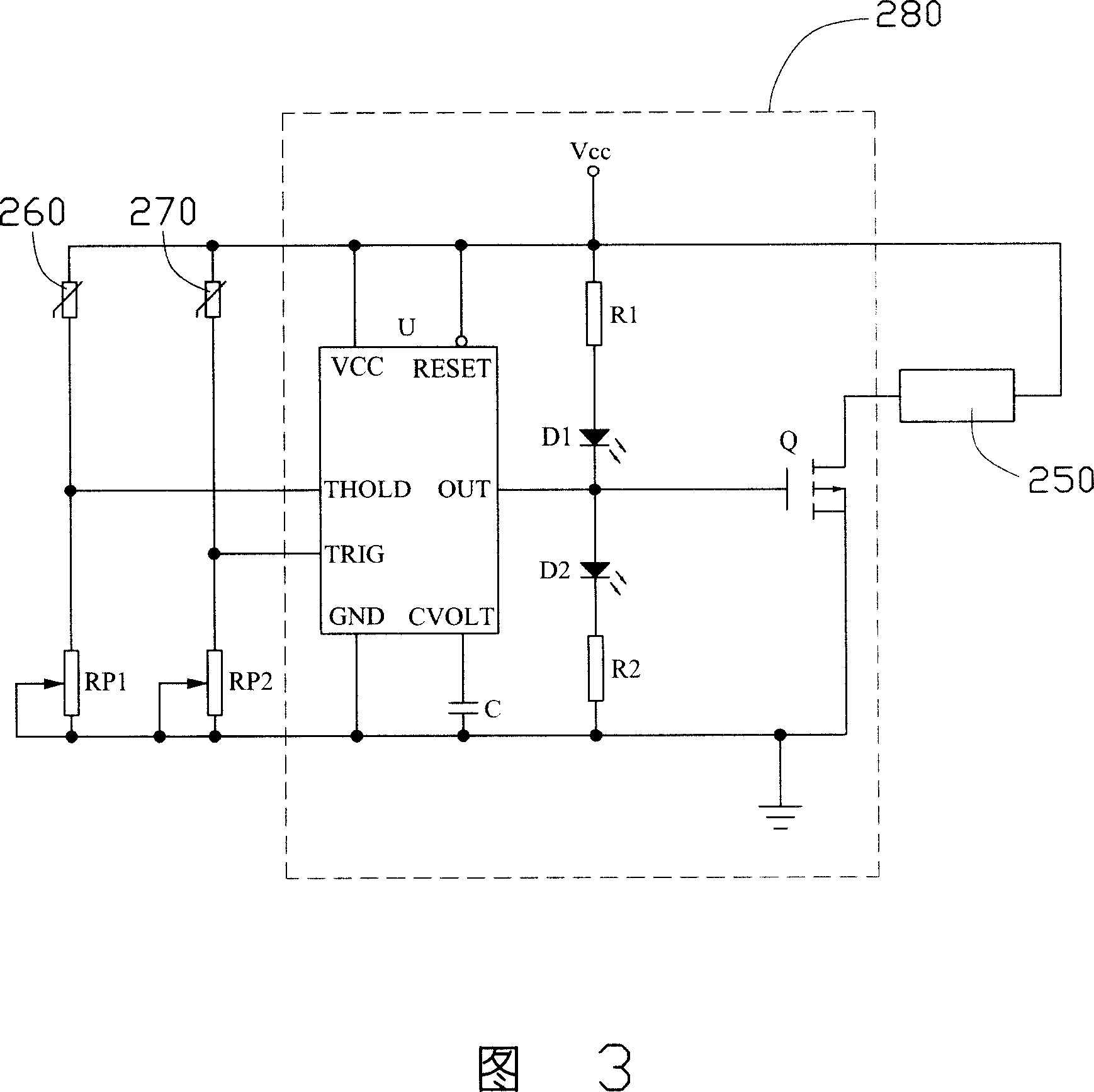

[0012] Please refer to FIG. 2 and FIG. 3 together. The heat dissipation device 200 of the present invention is used to dissipate heat to a heat-generating electronic component, such as a central processing unit 230. Its preferred embodiment includes a fan 210, a radiator 220, a heat conductor 240, a Semiconductor refrigerator 250, a sensor, and a temperature controller 280 (the temperature controller 280 can be arranged on the available space of the motherboard), and the sensor includes a first sensing element 260 and a second sensing element 270 .

[0013] Wherein, the central processing unit 230 is in close contact with one side of the heat conductor 240 (usually with heat dissipating paste between the two), and the other side of the heat conductor 240 is in close contact with the heat-absorbing side of the semiconductor refrigerator 250, and the first heat conductor Both the sensing element 260 and the second sensing element 270 are in close contact with the heat conductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com