Magnetically inductive flow rate sensor

A flow sensor and magnetic induction technology, which is applied to the volume/mass flow generated by electromagnetic effects, the application of electromagnetic flowmeters to detect fluid flow, measure flow/mass flow, etc., can solve the problem of sacrificing the operable flow range and achieve short magnetic field establishment time, low leakage inductance, and the effects of extensive shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] While the invention is susceptible to various modifications and alternative forms, illustrative embodiments thereof are shown by way of example in the drawings and described in detail herein. It should be understood, however, that there is no intention to limit the invention to the particular forms disclosed, but on the contrary, the invention is to cover all modifications, equivalents and alternatives falling within the spirit and scope of the invention as defined by the appended claims.

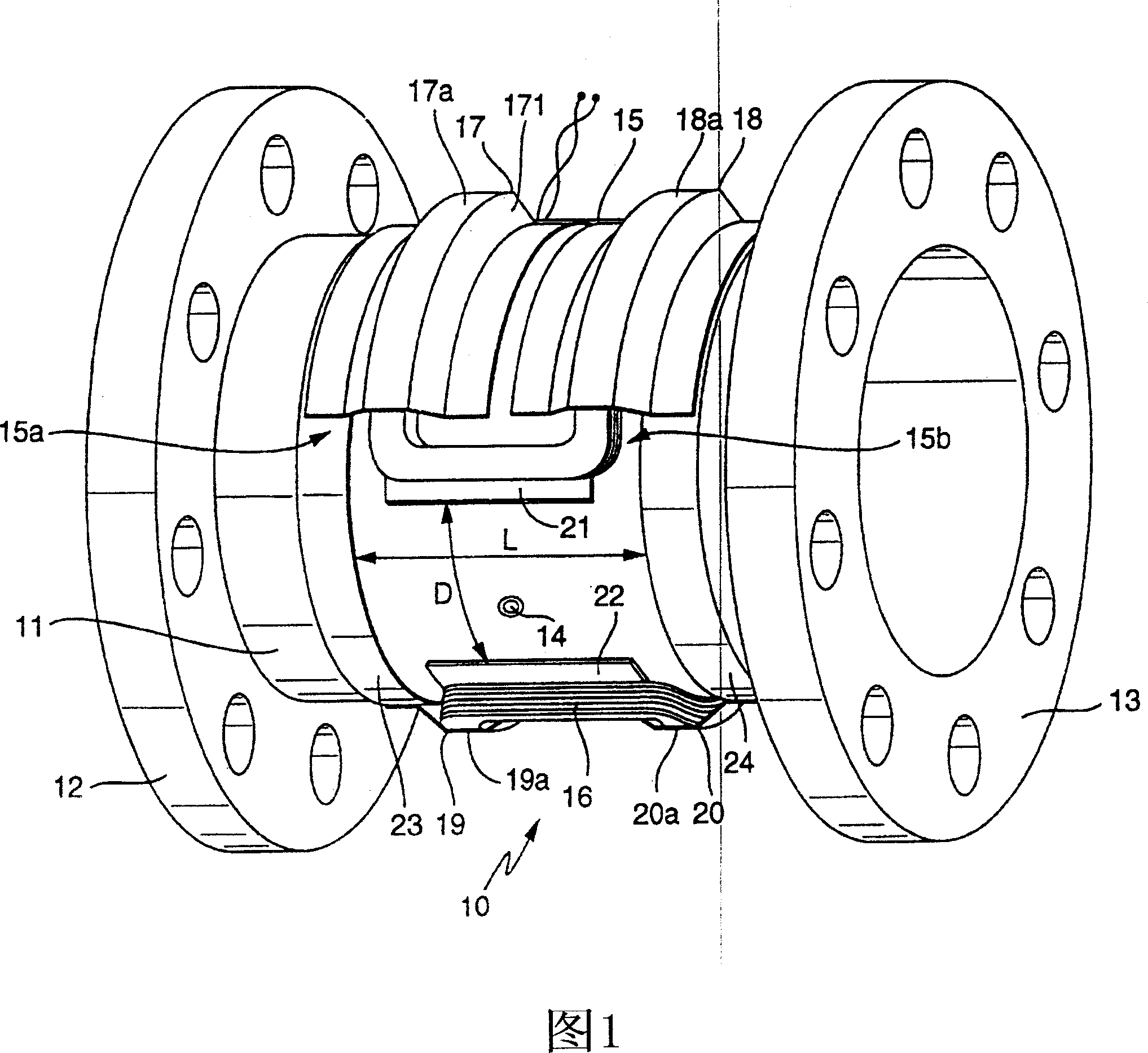

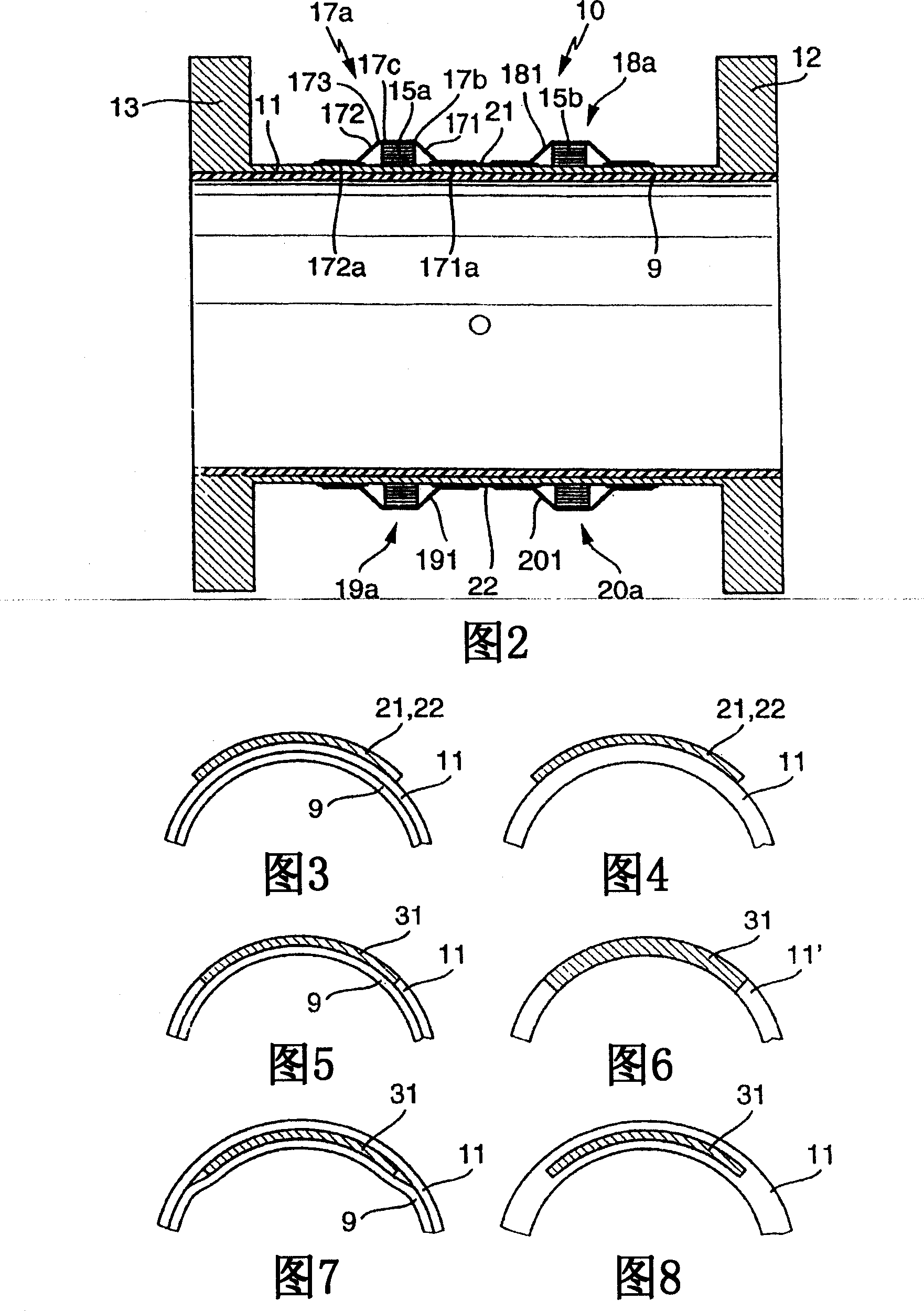

[0031] The magnetically inductive flow sensor 10 shown schematically in Figures 1 and 2 is particularly suitable for measuring conductive fluids flowing in pipes (not shown) having a nominal diameter in the range of approximately 200-700 mm, especially in the range of 350-600 mm. For guiding the fluid, the flow sensor has a measuring tube 11 which can be inserted into the pipeline. The measuring tube 11 can be made of a non-ferromagnetic material such as stainless steel, a suitable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com