Transformer

A technology for transformers and secondary windings, which is applied in the field of transformers and can solve problems such as the volume increase of transformers 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described below with reference to the drawings.

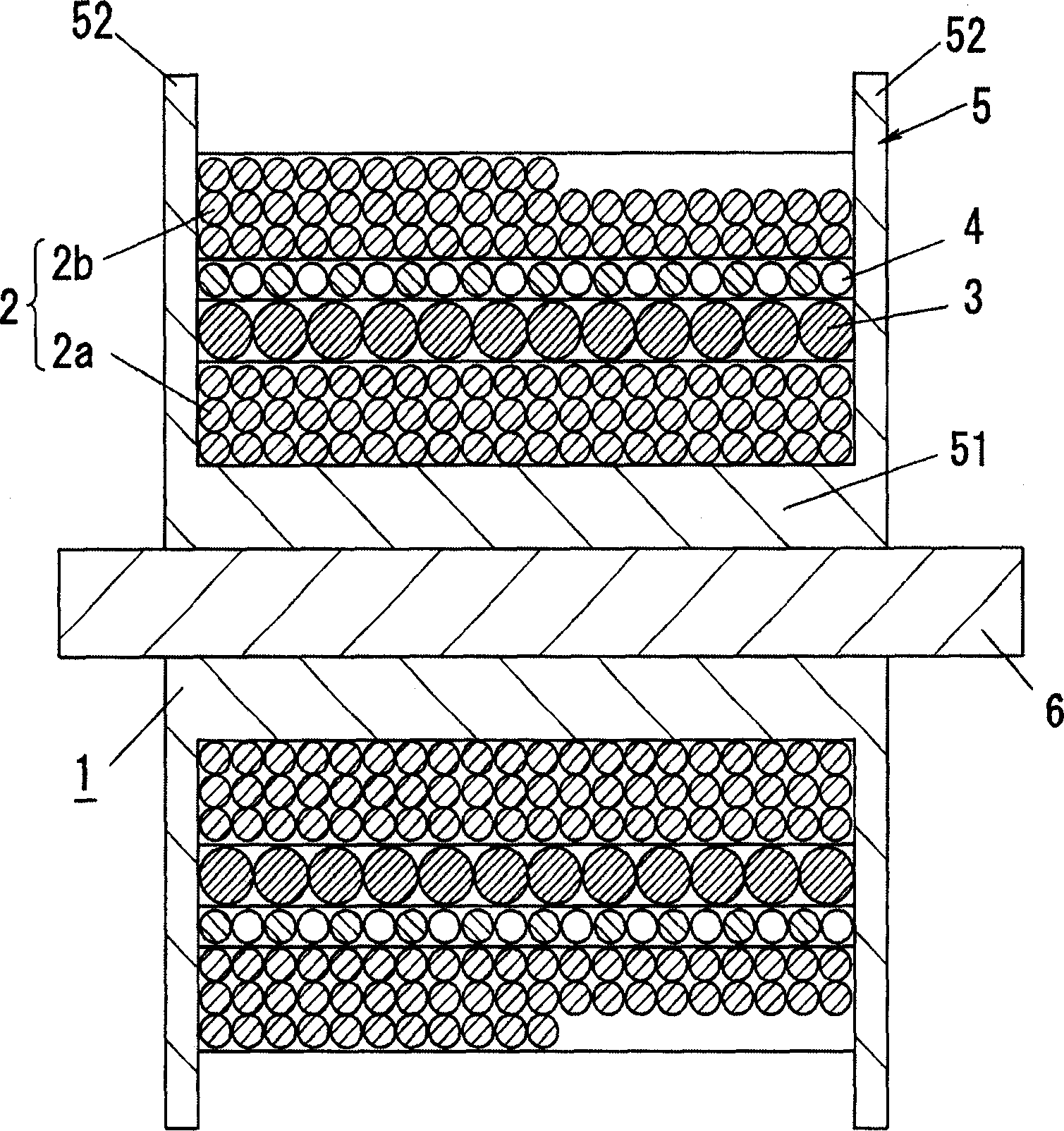

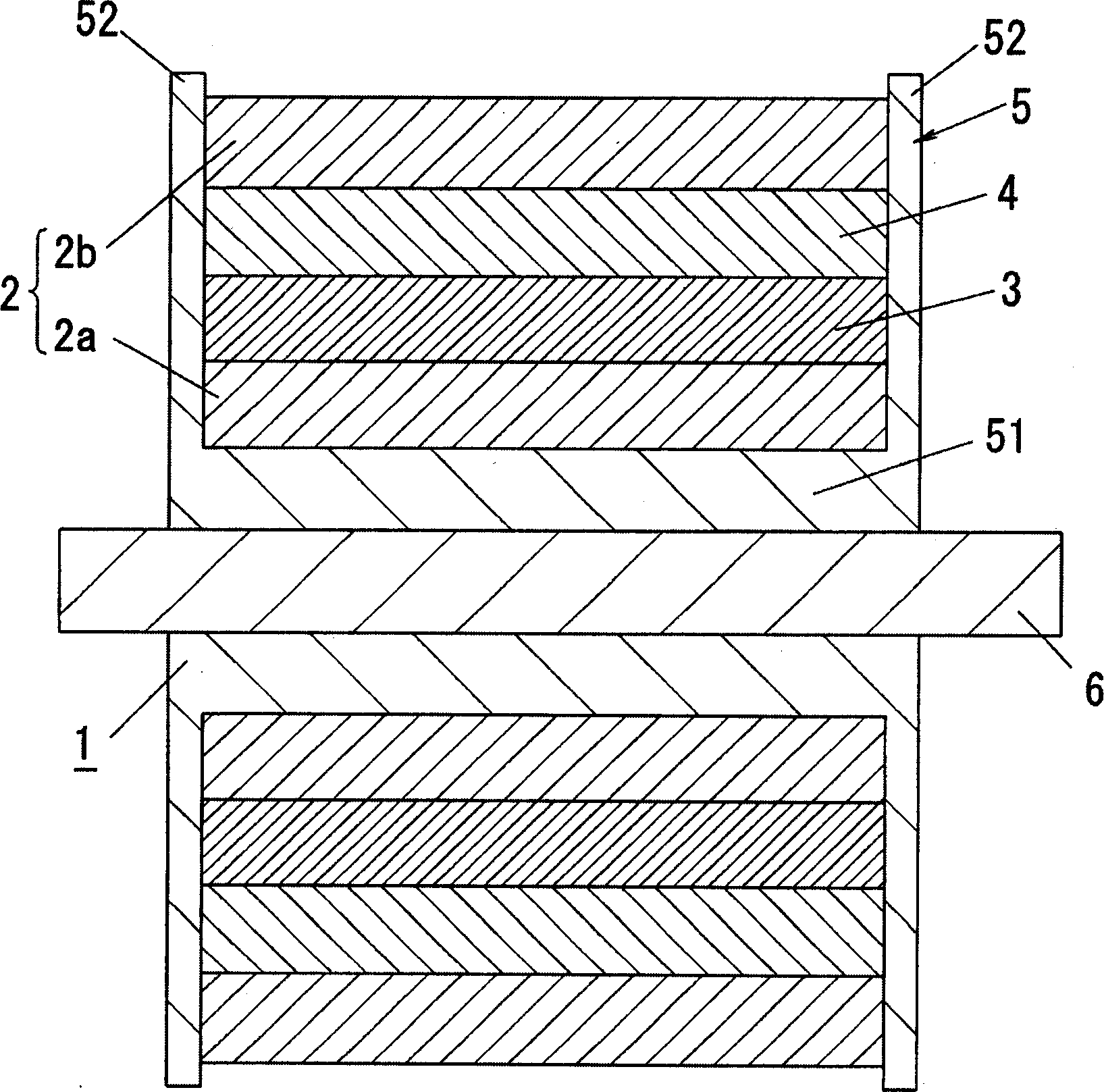

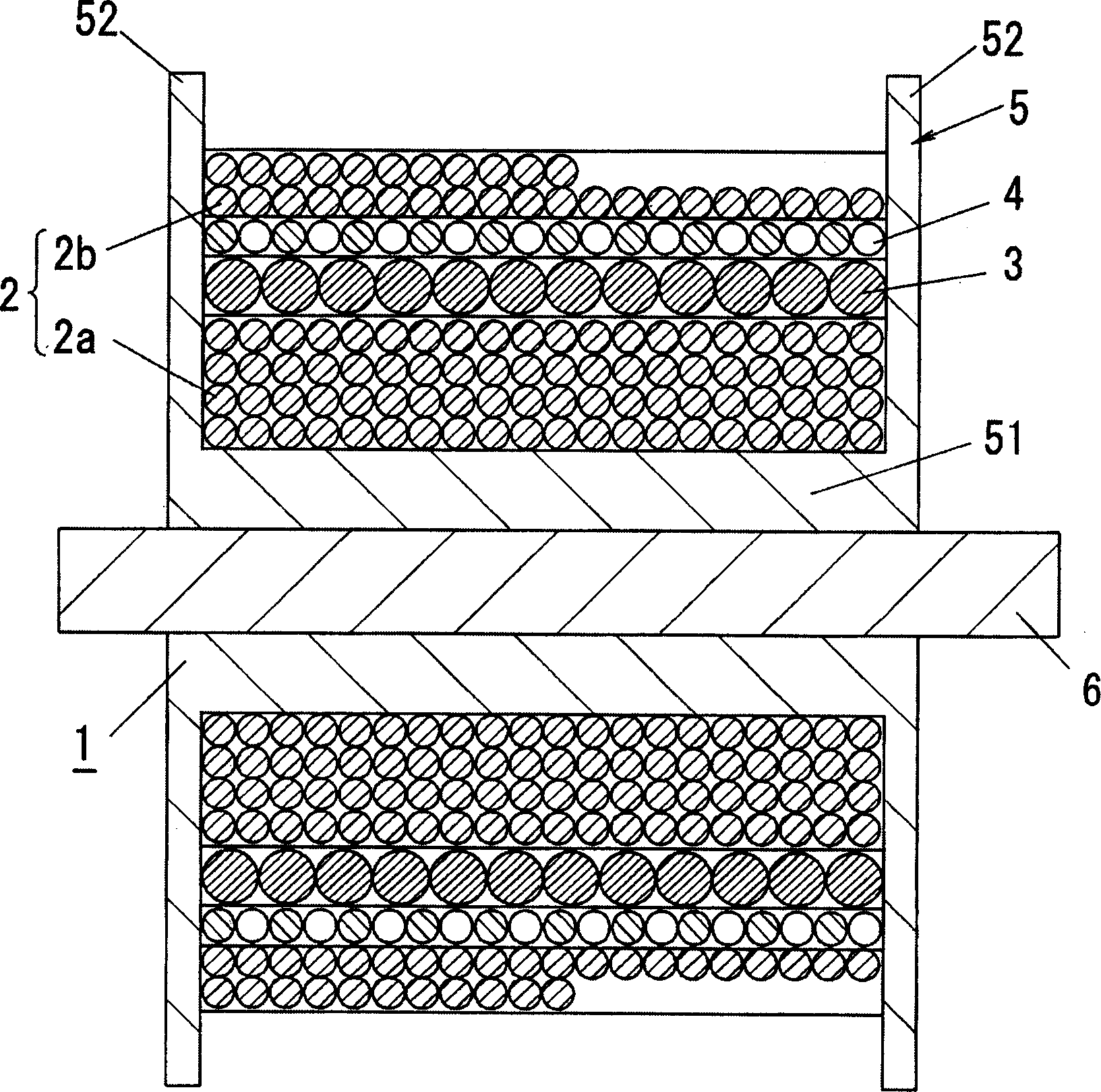

[0028] Transformer 1 of this embodiment, such as figure 2 As shown, it includes a cylindrical shaft portion 51 made of insulating material with a uniform outer diameter and a flange portion 52 protruding from both ends of the shaft portion 51 along the radial direction of the shaft portion 51; The magnetic body constitutes and penetrates the magnetic core 6 of the shaft portion of the bobbin 5; between the flange portions 52 of the bobbin 5, it is divided into four overlapping winding layers in the radial direction of the shaft portion 51 relative to the shaft portion 51, The primary winding 2, the secondary winding 3, and the feedback winding 4 wound on the shaft portion 51. The primary winding 2 includes the winding layer 2a located on the innermost side (hereinafter referred to as “the first layer”) and counting from the inside. The winding layer 2b of the fourth layer (h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com