Stone material processing method and stone material saw

A stone cutting and frame sawing technology, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of restricting the popularization and application of stone cutting saws, high manufacturing difficulty, low cutting efficiency, etc., and achieves improved cutting conditions and lubrication. And the effect of good cooling conditions and high cutting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

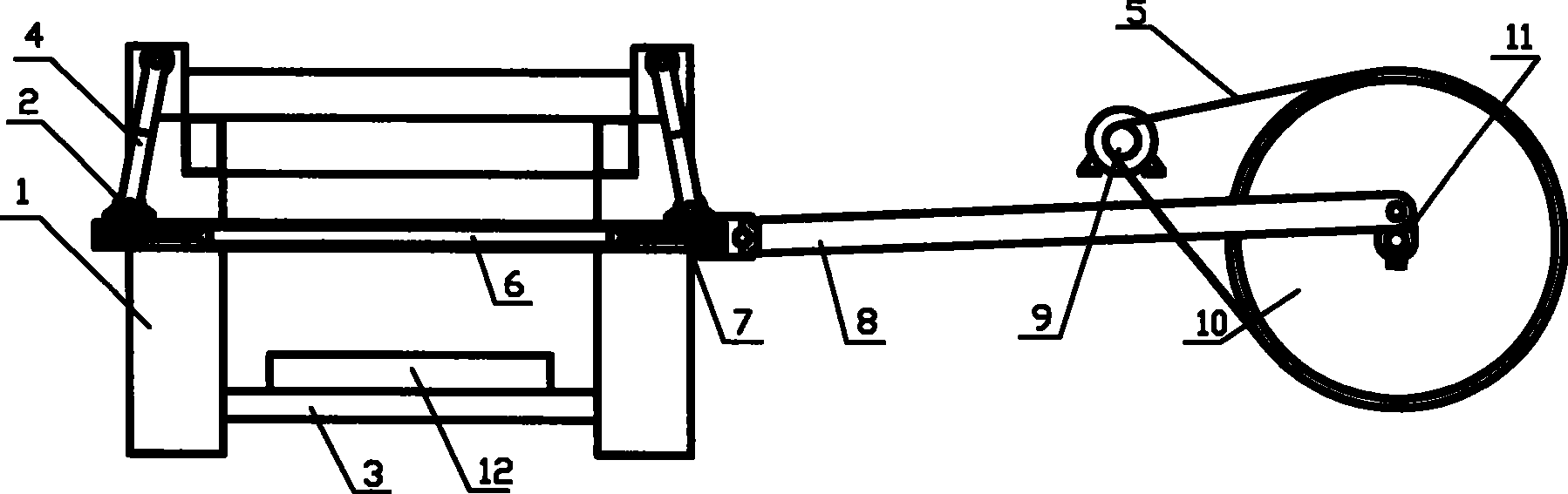

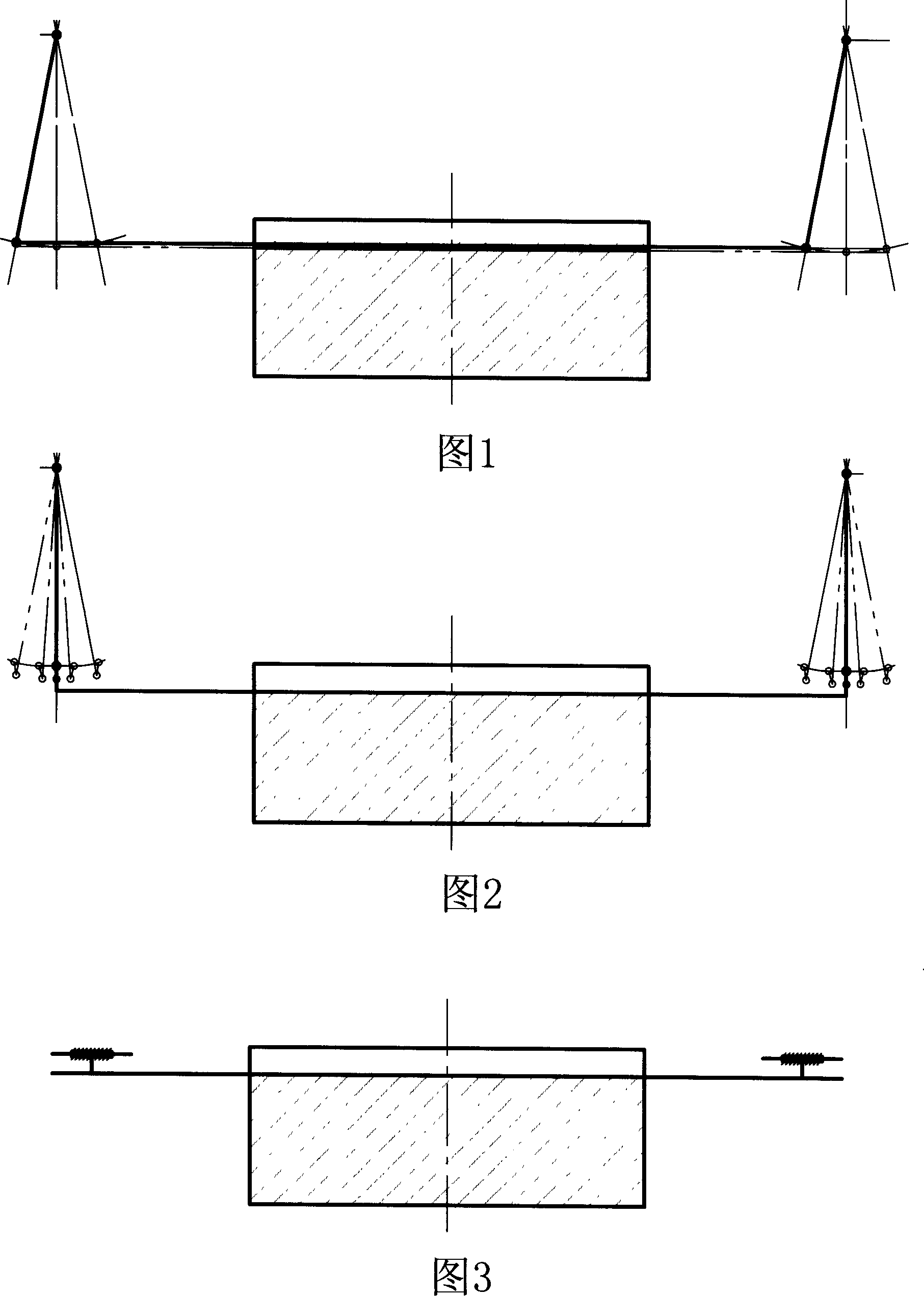

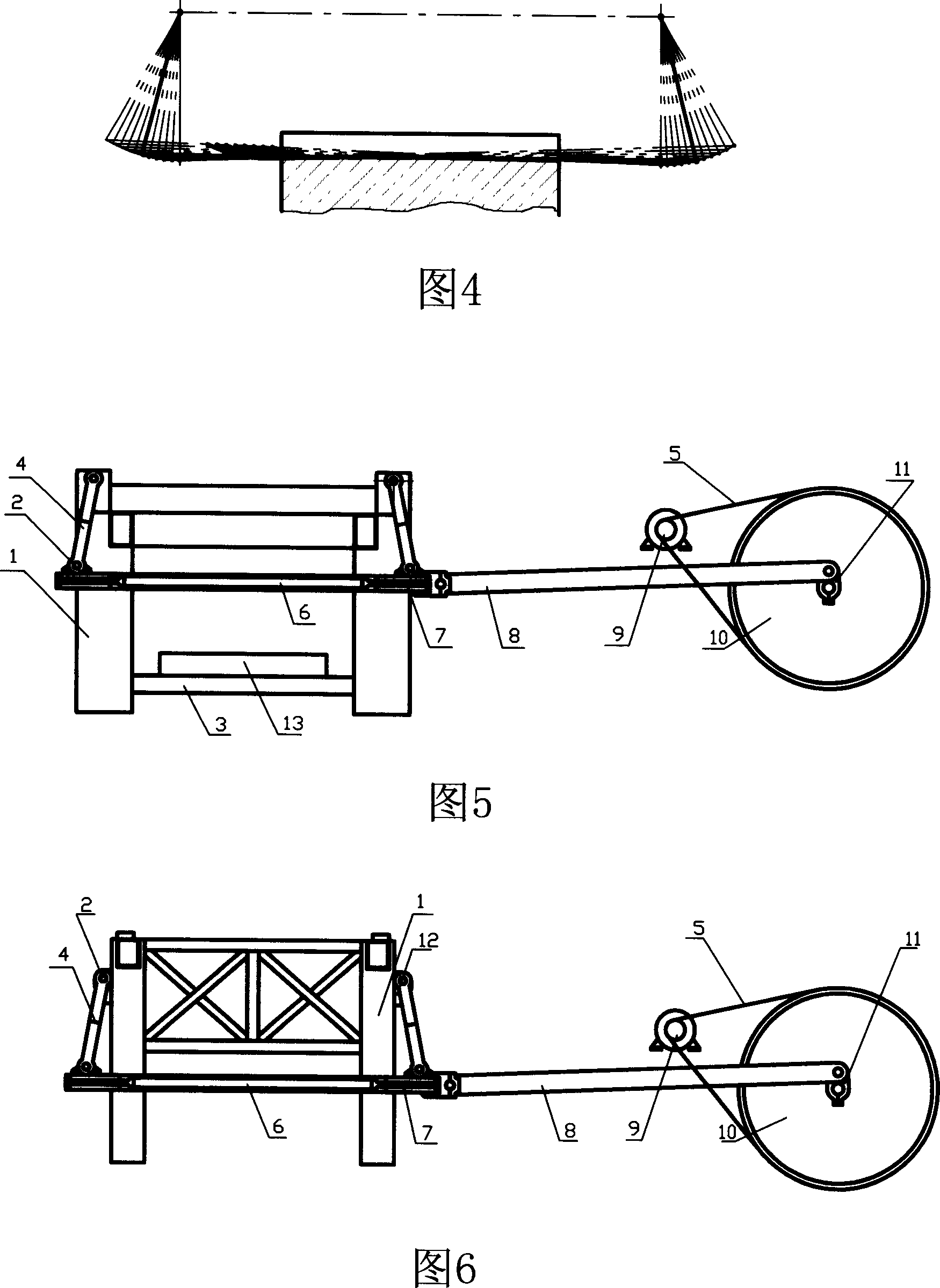

[0022] As shown in Figure 5, the body is made up of four uprights 1 and an elevating platform 3 that cooperates with the uprights 1. A lead screw is arranged on each upright, and the screw nut that cooperates with it is fixedly connected with the elevating platform 3, and the upper end of the swing arm 4 is connected with the elevating platform 3. The upper part of the column 1 is hinged. During use, the lift table 3 lifts the workbench 13 and the stone to lift, so as to realize the feeding of the stone and cut the stone. Two swing arms 4 with equal length, the lower ends of the swing arms 4 are hinged to the saw frame 7, the saw frame 7 is connected to the connecting rod 8 in the crank linkage mechanism, the crank linkage mechanism is driven by the motor 9, and the crank linkage mechanism and the motor are arranged There are flywheel 10 and transmission belt 5, and flywheel 10 is connected with motor 9 by transmission belt 5. The crank 11 in the crank-link mechanism has one e...

Embodiment 2

[0024] As shown in Figure 5, only the diamond saw blade in Embodiment 1 is replaced with a sand saw blade.

Embodiment 3

[0026] As shown in Figure 6, two swing arms 4 with equal lengths, the lower ends of the swing arms 4 are hinged to the saw frame 7, the saw frame 7 is connected to the connecting rod 8 in the crank linkage mechanism, the crank linkage mechanism driven by the motor 9, and the crank linkage mechanism A flywheel 10 and a transmission belt 5 are arranged between the motor and the motor, and the flywheel 10 is connected with the motor 9 through the transmission belt 5 . In the crank-link mechanism, the crank 11 has one end fixedly connected to the flywheel 10, and the other end fixedly connected to the central axis of the flywheel 10. The unilateral swing of the swing arm 4 of this structure can make the saw blade 6 cut continuously in the whole stroke. The axial distance between the two hinge shafts 2 at the upper ends of the two swing arms 4 is smaller than the axial distance between the two hinge shafts 2 at the lower ends of the two swing arms 4, so that the cutting trajectory o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com